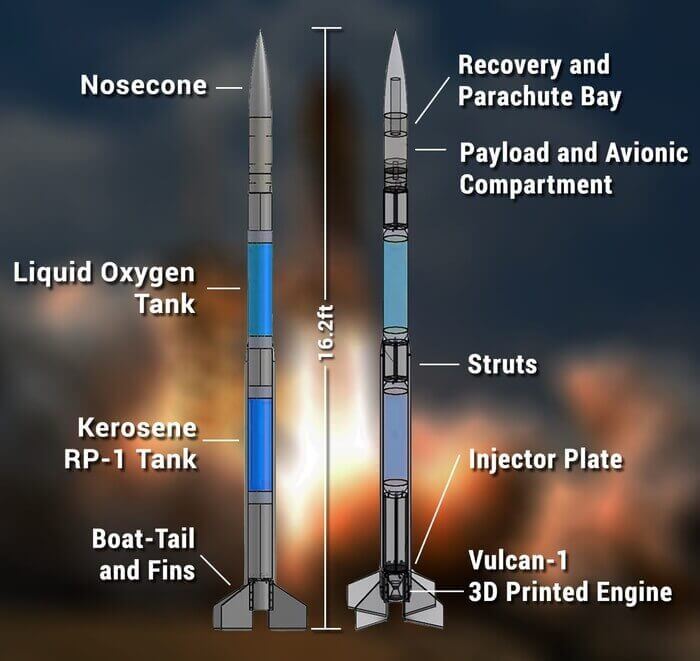

This Kickstarter project is literally flying high. The first students that have previously designed, 3D printed and tested a rocket engine are now aiming higher. Their advanced design of a 3D printed rocket engine is called The Vulcan-I. It is a “bigger, better, but completely different design” in comparison to the original Tri-D engine, the team says.

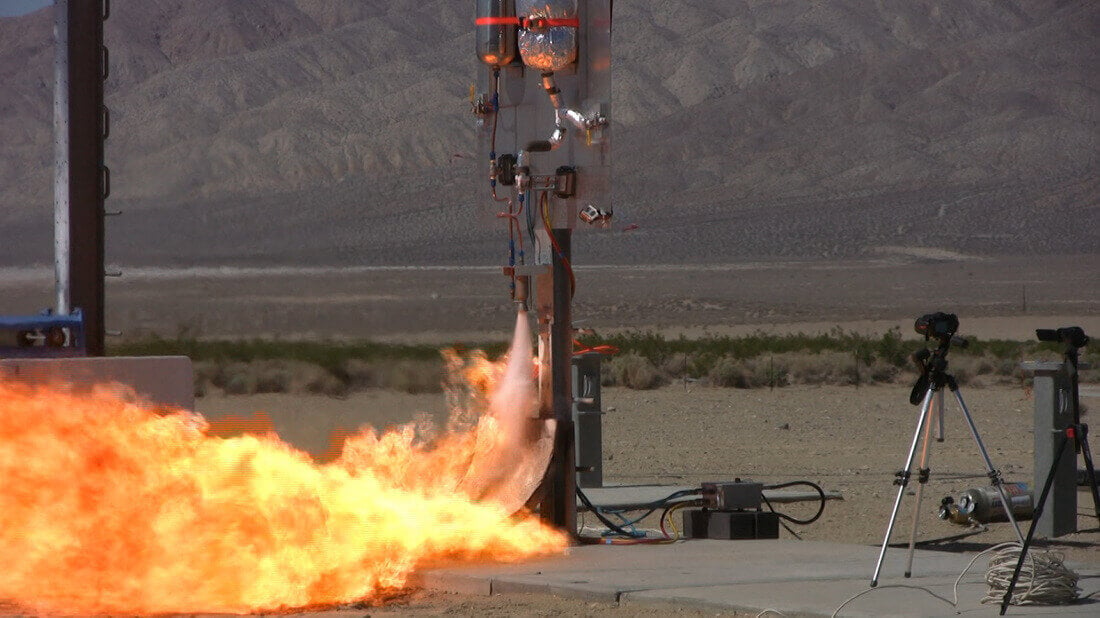

They’re not doing anything halfway: Hot fire tests have been completed, the first in April and the second one on 4th of June. If all goes according to plan, the Vulcan-I will be part of a rocket body being launched in June (no specific date announced yet), making the campaign creators SEDS group (Students for the Exploration and Development of Space) at the University of California record holders at least twice:

1. first student organization to launch their rocket engine in a rocket

2. highest flight of a rocket by a 3D printed engine

The Kickstarter crowdfunding campaign for the Vulcan-I closed with more than 25% overfunding. Initially, the team wanted to collect 15,000 $, which is not much for a crowdfunding campaign. The difference to other campaigns is that backers get a few nice goodies, but they are not crowdfunding a product like a 3D printer that the backers get once it is produced. Bear in mind, a team of undergraduate students that want to lift their own rocket into space are getting that money.

The specifications of the Vulcan-I rocket body allow for a flight altitude of 3 kilometers. This may not even reach the stratosphere, but still is impressive for a rocket prototype. They say the rocket provides a thrust of 340 kilograms, which is a number I can not really compare to anything. Only so you have one reference for comparison, the NASA Space Shuttle produced a sea level thrust of 179,097 kilograms.

The very same student organisation has already researched the feasibility of 3D printed rocket engines. They sucessfully designed and tested a metal 3D printed rocket engine.

“It was an amazing feeling,” said Deepak Atyam, SEDS president. “We could all feel the power of the engine in the bunker. It’s something you can’t really describe.”

As the first university worldwide to use a 3D printed rocket engine, on 5th of October 2013, their Tri-D system made headlines. Its successor, the Vulcan-I, is one of a few prototyped 3D printed engines in the world.

What is so revolutionary about the Vulcan-I is not only that it is the first rocket with a 3D printed engine, but the fact that a student organisation has the capabilities to launch a prototype they cannot afford to build or launch by themselves. While a single person may have no direct advantage of what they do, many people decided to spend some of their money on this project.

Why? This project touches one of humanities’ desires: Exploring the vast endlessness surrounding us that is space. The fact that a 3D printed rocket engine made by students, not rocket scientists, is a promise. That rocket science is not always proverbially rocket science. A promise that maybe space travel gets so affordable not only the richest people on the planet get to enjoy it. A promise that there is a technology that improves so fast it will make our lives better by any means. Or, as the SEDS team express themselves with joy:

“It also could prove to the world that we are more ready to be an interplanetary species than ever before.”

License: The text of "Heavenwards: Vulcan-I, the 3D printed rocket engine" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.