Researchers have developed a “hyperelastic bone” material which could be used to 3D print implants and help heal fractures within weeks.

The material can be used to 3D print flexible bone implants. 3D printing allows for the bones to be customized and manufactured in any size, shape or form. Surgeons can also manipulate the resulting bones which are both robust and very elastic. Current methods of fixing or replacing bones are awkward and expensive. With this new material, healing fractures could be set to change in as little as five years.

The new synthetic material was developed by assistant professor of materials science at Northwestern University, Illinois, Ramille Shah and her colleagues.

Shah says : “Our vision is to have 3D printers in a hospital setting where we provide the hyperelastic bone ink, so surgeons can make individual implants within 24 hours. You could make off-the-shelf, or patient-specific implants using scans from patients.”

Hyperelastic bone has so far been tested on rats. It was also used to repair the spinal defects in mice, as well as to fix a hole in the top of a monkey’s head.

How Does the 3D Printed Hyperelastic Bone Material Work?

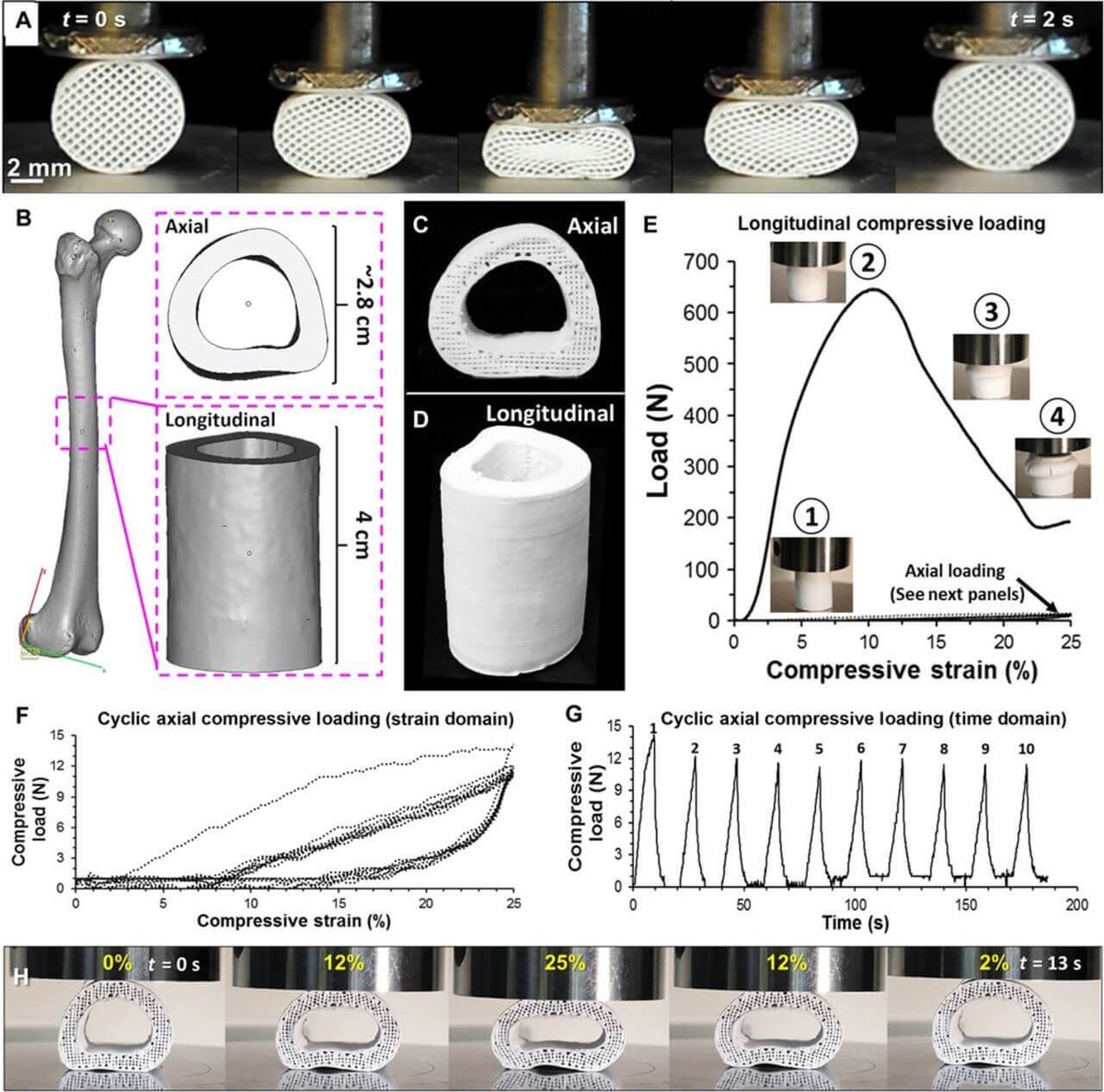

The hyperelastic bone is made from a mineral called hydroxyapatite which is naturally found in bone. The mineral is brittle and so the researchers mixed it with a PLGA, a polymer that binds the mineral particles together.

This added also flexibility to the material. Shah said: “We were very surprised to find when we squeezed an implant, it bounced back to its original shape.”

The hyperelastic bone can replace bone matter or be used as a scaffold, implanted under the skin for new bone to grow on. The implants are infiltrated by blood vessels, once in place, and slowly turn into natural bone.

Shah and her team assume the material could heal many different skeletal problems. They expect to start testing the material on humans within as little as five years.

By using a 3D printer, the artificial bone can be manufactured cheaply and stored for at least a year. However, the printer itself comes with a hefty price tag of around $260,000. But, could it be worth the cost, if it changes the world of orthopedic and craniofacial surgery?

Watch the New Scientist video below to get an overview of the hyperelastic bones:

More info: Science Translational Medicine

License: The text of "3D Printed Hyperelastic Bone Could Heal Fractures in Weeks" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.