Win an All3DP article all about you, your company, and how 3D printing helps you create, innovate, and succeed!

3D printing with Formlabs Fuse 1 SLS & 3L SLA help develop the concept cars of tomorrow.

How generative design & 3D printed prototypes helped bring the world's most innovative fishing pliers to market in less than three months.

High-quality, affordable 3D printed prototypes enabled a budding fitness entrepreneur to test and perfect his innovation, and bring the Harambe System from idea to market faster.

Virtually any vehicle part can be recreated or restored with 3D scanning and 3D printing ensuring that classic cars keep rolling.

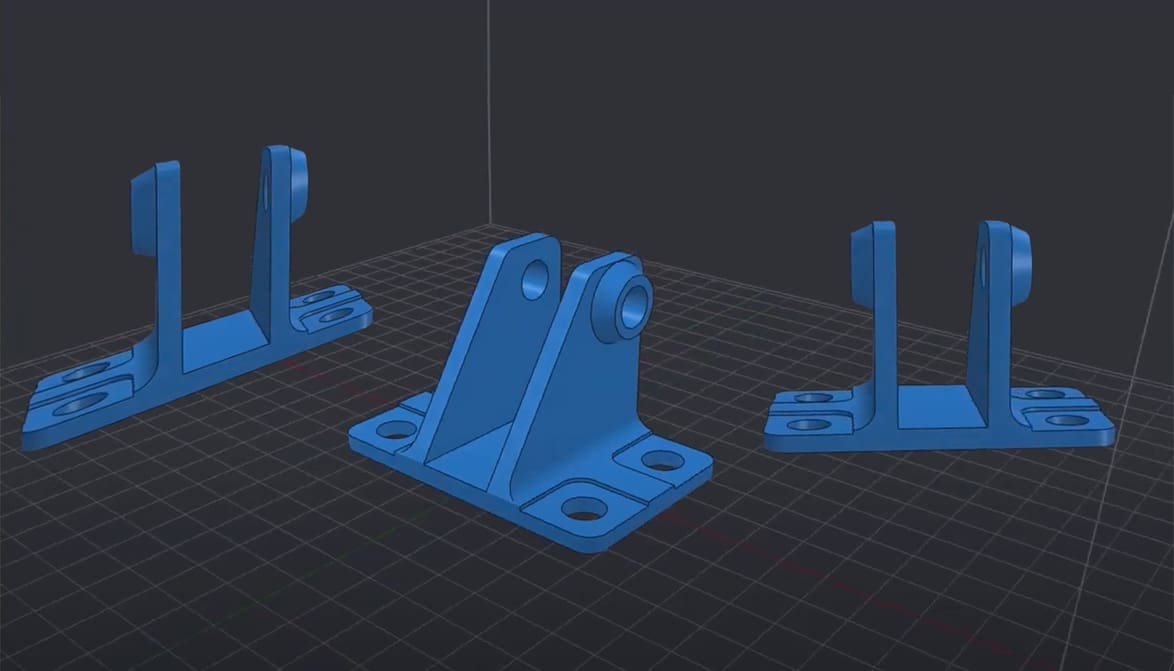

What is the cheapest and fastest way to manufacture 50 simple brackets? We asked traditional and additive manufacturers for quotes then compared it to buying your own printer.

Mercury Systems speeds up PCB manufacturing by replacing a costly injection-molded tools with in-house designed and 3D printed versions.

Ex-Olympian's 3D printing business helps fellow paralympic athletes compete at a higher level.

3D printed parts are, right now, circling the earth, delivering satellites into orbit, and roaming the surface of distant planets. See how NASA-backed innovations are driving 3D printing adoption and innovation here on Earth.

To celebrate Earth Day 2021, All3DP sat down with additive manufacturing company Ai Build to ask: Why do you print with recycled filament?

Süß and friends, a start-up German 3D printing service that helps clients develop their ideas into sellable products.

Forecast 3D was already a successful 3D printing service with clients ranging from aerospace giants to well known designers, but when it shifted to printing PPE during the pandemic, the healthcare industry realized what others already knew: 3D printing makes manufacturing products faster and removes complexity.

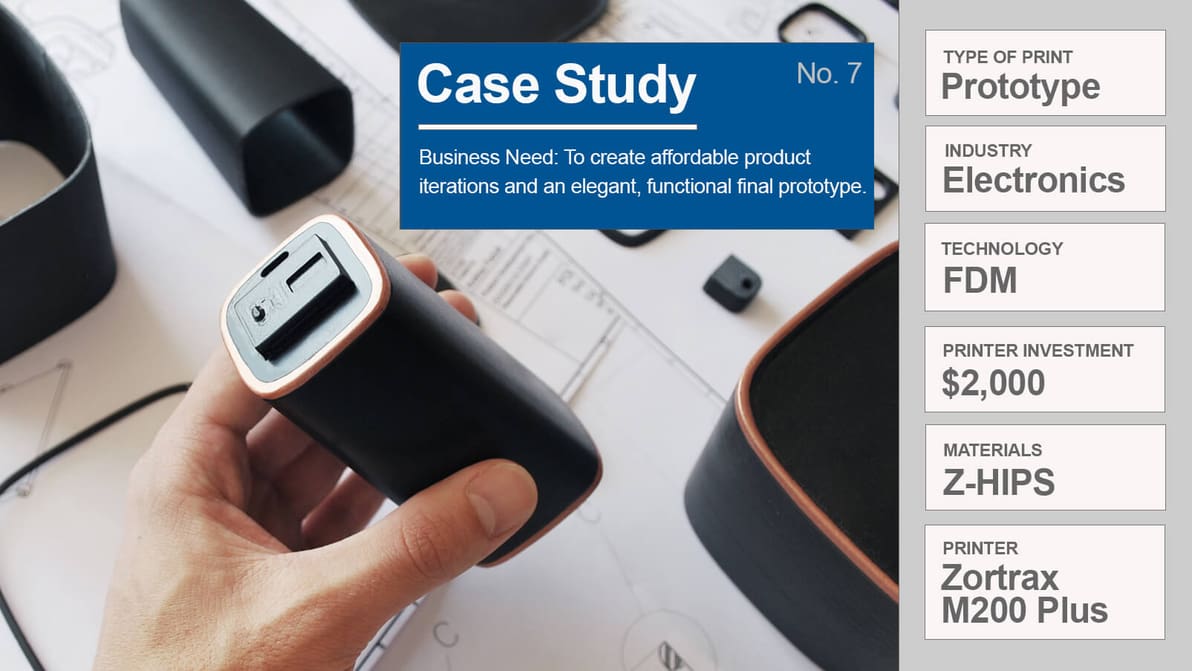

Beautiful and functional product prototypes aren’t just for big-budget design firms anymore. New 3D printing technology puts great-looking prototypes – and quick and cheap design iterations – within reach for practically any professional.

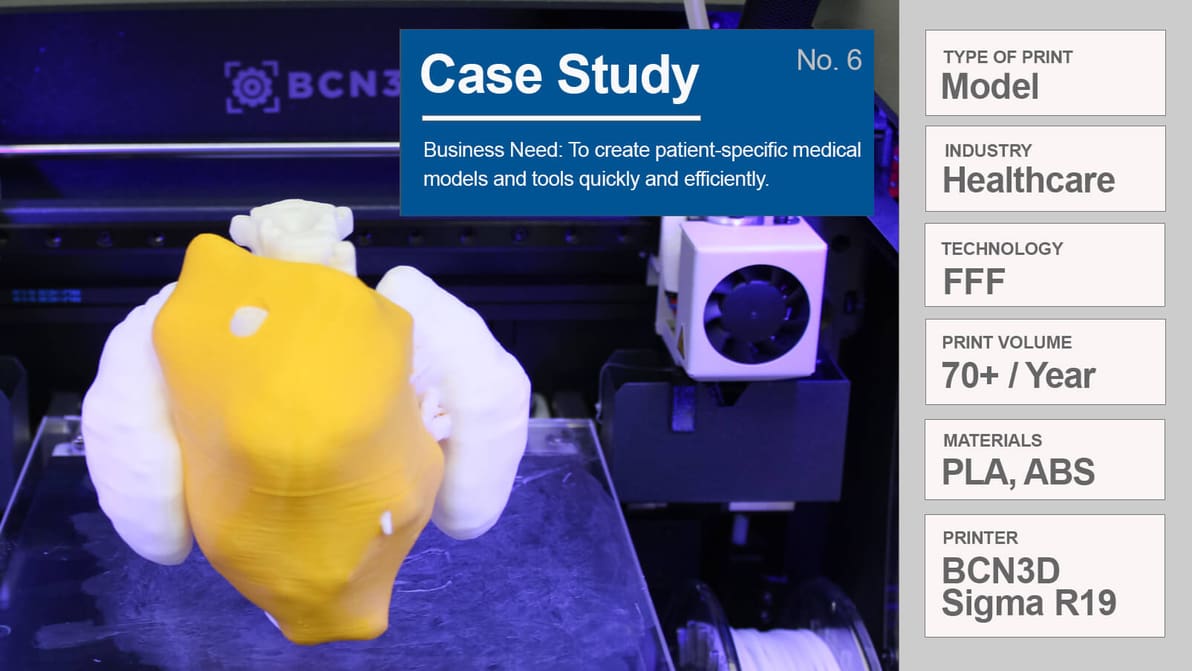

Someday soon, all hospitals may have 3D printing units capable of making patient-specific three-dimensional models and tools essential for diagnosis, treatment, patient education, surgical planning, and in-OR guidance.

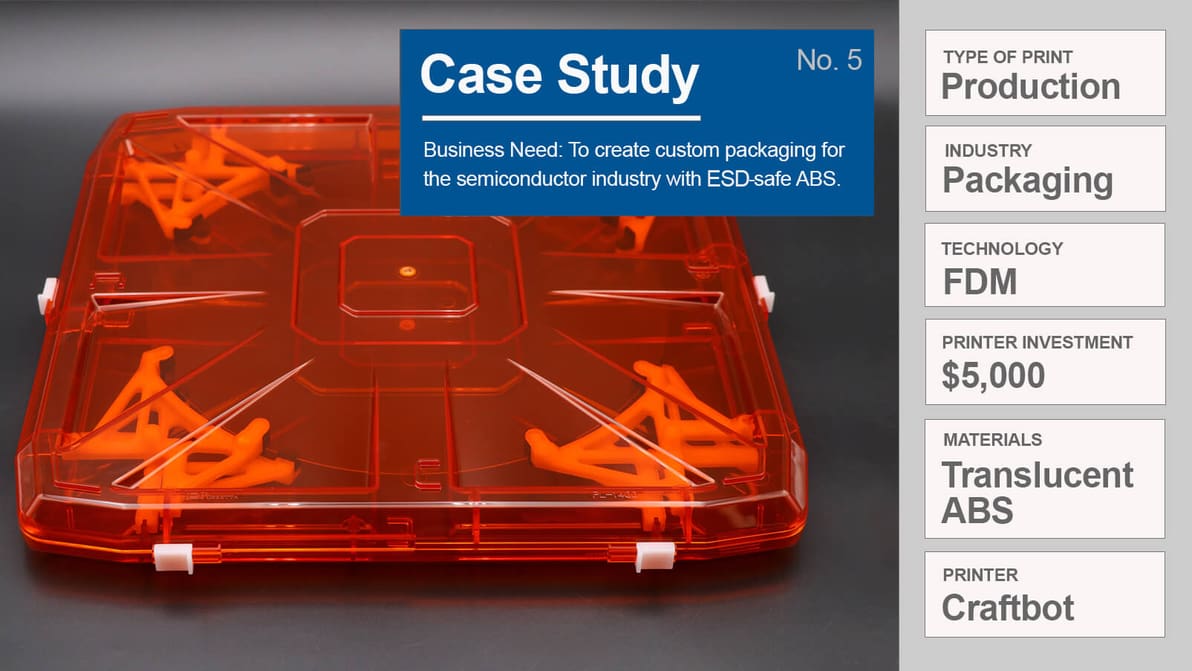

Not satisfied with off-the-shelf solutions, Pozzetta Products decided to make its own ESD-safe filament and turn a fleet of Craftbot 3D printers into a production factory.

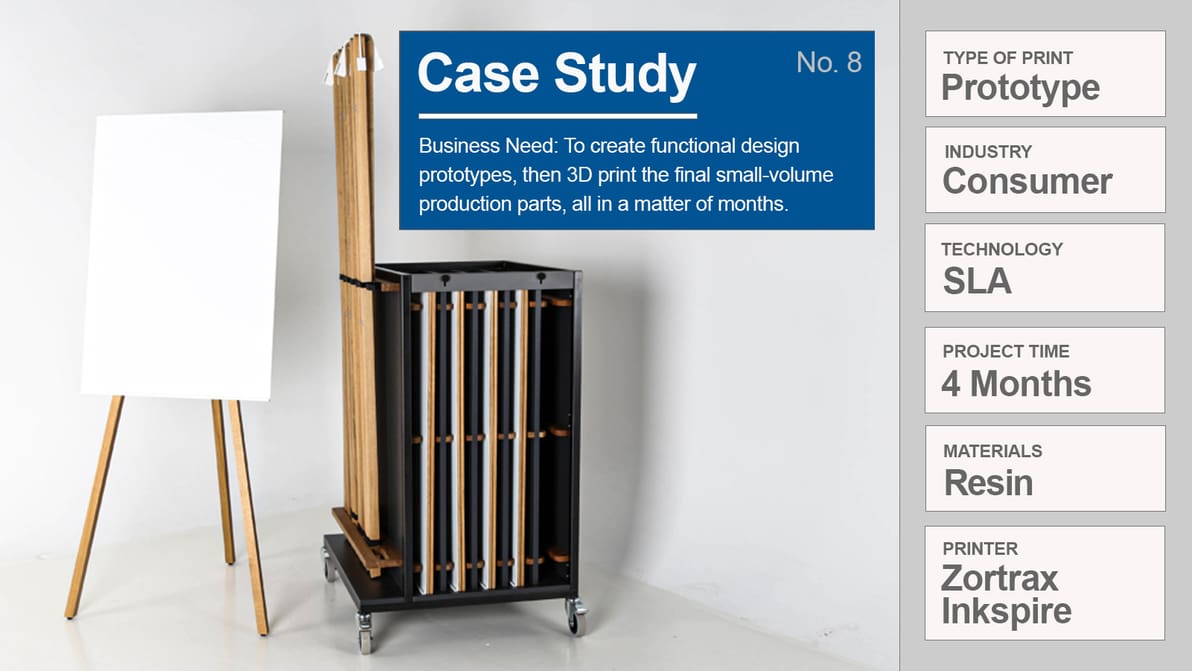

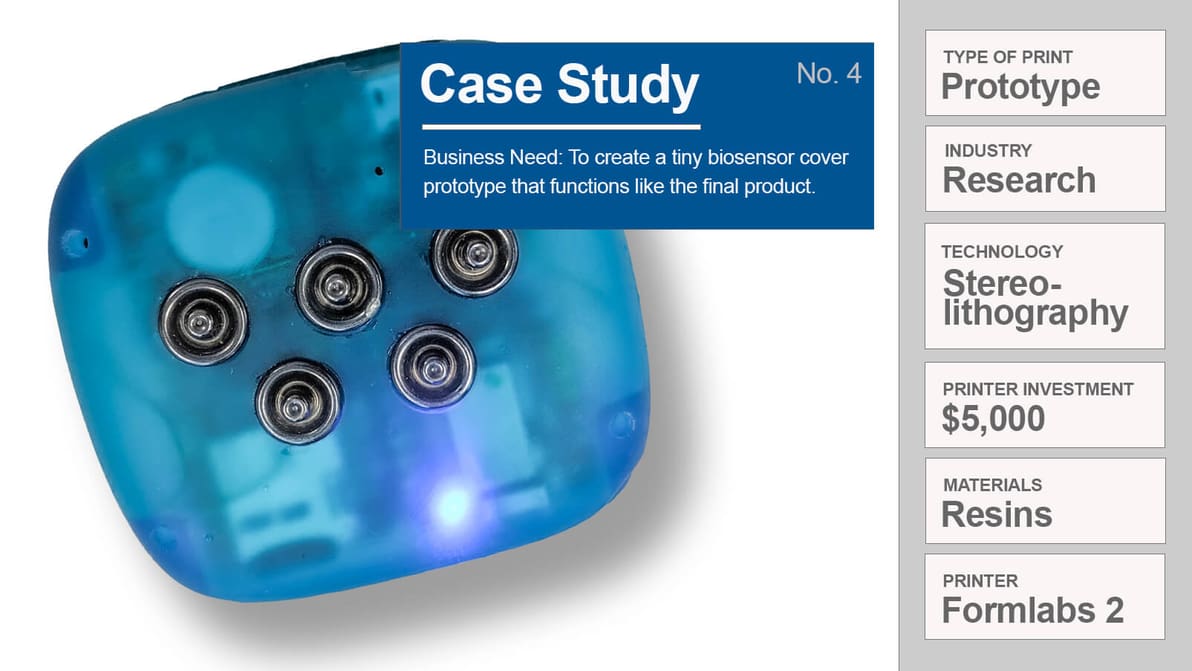

Affordable, versatile resin 3D printers let research engineers experiment on printed prototypes that look and act more like a final product.

Two innovative Swedish companies – one in jewelry design and one in metal 3D printing – collaborate to push the boundaries of 3D-printed wearable art. Take a look at this Digital Metal case study to learn more.

How a Guatemalan architect creates stunningly intricate furniture designs achievable only with a large format 3D printer.

How one automotive parts company invested in 3D printing to solve a tool problem and ended up saving 70% of costs and transforming their operation.