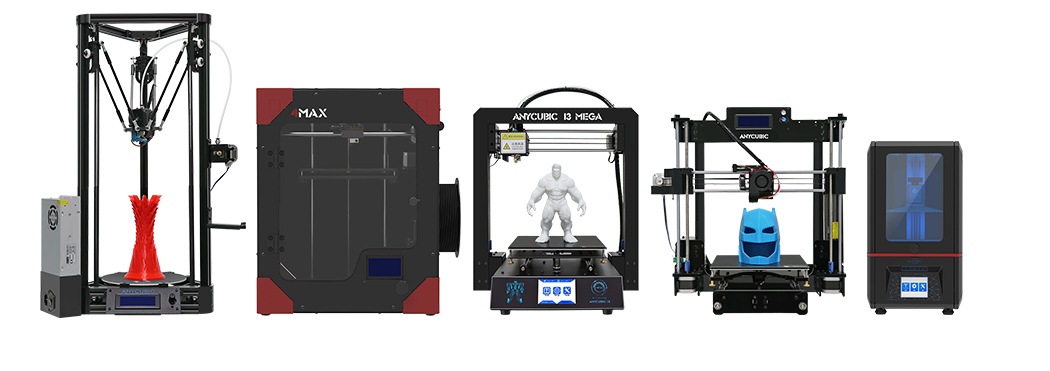

Since Chinese manufacturers have entered the low-cost 3D printer market, Shenzhen Anycubic Technology has been providing users with highly interesting 3D printers for a reasonable price – like the FDM 3D printer Anycubic i3 Mega or the DLP-based Anycubic Photon. We wanted to provide you with more information on the company, so here’s an interview with Anycubic’s Deputy Manager James Ouyang.

Could you please give us a short background how Anycubic started out?

James Ouyang: Anycubic was founded in September 2015 by a group of childhood buddies who determined to make a difference in the consumer 3D printer market. Before that, I graduated with a Chemical & Material Engineering Ph.D. degree from the University of Auckland. I lead the R&D team, and the rest has been well taken care of by the other partners.

What makes the company different from other 3D printing companies?

Anycubic believes 3D printing technology should be accessible and affordable rather than being rocket science. We are specialized in supply chains, online markets, and customer service, and most importantly we have gathered a bunch of genius engineers, so we are very much confident to keep offering the best value of 3D printer worldwide.

How many people are currently working for Anycubic?

Currently, Anycubic has 180 employees, working on 5500 square meters.

What‘s your best-selling product so far? What do you consider your biggest success?

The Anycubic Mega and Kossel are popular FDM 3D printers, while the Anycubic Photon is getting more attention as a reliable hobbyist DLP 3D printer. We consider the biggest success is we are enjoying what we are doing, and customers are happy with our products.

How do you provide customer support worldwide?

Our after-sales and technical support team are required to respond to emails within 24 hours worldwide. We make YouTube tutorials and run Facebook support pages as other decent 3D printer companies do. Also, we are developing a more efficient and user-friendly customer care system via our website, because we consider that would make Anycubic brand different in the long run.

What was the biggest challenge in developing the Photon?

We basically know nothing in detail about the DLP technology at the beginning, so that was the biggest challenge. Indeed, it took us ages to make progress in light source and firmware. However, we see that as an advantage as well, because we could develop a 3D printer totally from a newbie’s perspective. And thanks to our talented engineer team, we did it.

Who’s the intended customer for the Photon?

Anyone who is interested in ultra-fine printing results and does not want any hassles. However, the customers should know that the resins need proper handling and they are totally different from the filament used in the FDM 3D printers.

How is the Photon different from other DLP printers on the market?

In the same price range, the biggest difference would be that the Photon has its optimized firmware and slicing software for both Windows and Mac OS. So the first-time users will not be required to do complex internet connection and debug. The offline printing process is basically simple as a traditional plug-and-print FDM 3D printer. The Photon could also provide reliable and high-resolution printing results as it is equipped with a 2K LCD screen.

Are there any new developments we should know of?

For the Photon, we are developing cool features such wireless connection, cluster control, built-in resin database, and even automatic resin feeding could be developed in the near future. We will update the firmware or the slicer monthly, so the Photon users could always get the latest features by just updating. Besides, the Photon X, a more professional and big DLP printer is on the way. Lastly, we would like to hear more suggestion from the 3D printing community.

License: The text of "Interview with Anycubic: 3D Printing for the Masses" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.