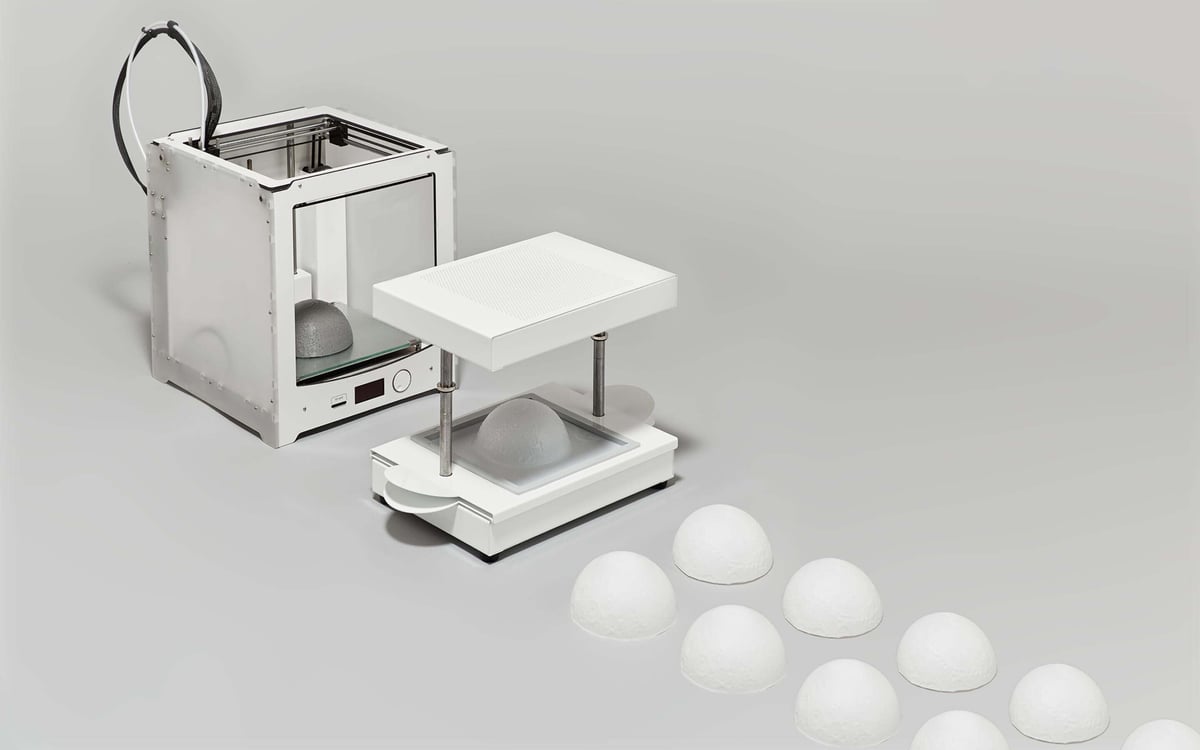

The FormBox is powered by your vacuum cleaner and claims to be quicker than a 3D printer. Could this be your next Kickstarter investment?

For makers and small businesses everywhere, the FormBox desktop vacuum former could be a remarkable piece of machinery. ALL3DP spoke with one of the team to learn more about the product and the campaign.

According to his bio, Benjamin Redford is no stranger to Kickstarter campaigns and knew what he was doing when it came to launching the FormBox. But he still wasn’t expecting quite such a huge response. He said: “It’s gone wild which has been great.”

Redford and his partner, Alex Smilansky, have just ten days left on their campaign but it has already far exceeded the funding goal of $50,000 by a factor of 10. The current tally is over half a million dollars and counting.

When asked whether Redford was ready for the next stages, he claimed he was “born ready”. He added: “Currently our machines are made in Wales, a decision that was made when we thought we were going to be making 200, but now we have quite a lot so we are probably going to explore some distributed manufacturing in countries where they are being delivered in the next couple of months.”

Although this impressive project has only taken a year to come to life, Redford’s inspiration came a lot earlier on. He said: “For my Goldsmith’s University Degree, I actually turned a normal drill into a rotational molder, I put a lot of molds in the washing machine and I turned a sewing machine into a band saw. I started working on trying to melt metal in the microwave, you can melt metal if you put ceramic in the microwave, but they wouldn’t let me do that.”

Working at Mint Digital in China, Redford noticed that there were many different machines which could be made to fit your tabletop. Once he realized this, he said: “I came home and quit my job and me and Alex started this project.”

How can a FormBox Complement a 3D Printer?

Redford is enthusiastic about 3D printing, but was quick to point out how a FormBox could aid any hobbyists. He said:

“In my experience with 3D printers I love them, they’re amazing. When I was in this factory in China, they had a 3D printer to prototype but they had loads of other machines as well.”

Redford’s main aim is pretty simple: “We want to make all of those other machines super easy to use and to a desktop scale. That’s what gets us excited, when you make something it is not just one process. There are a few machines that come around 3D printers.”

He reckons this is great for his company as there aren’t many people creating desktop tools to complement 3D printing, he explains: “We have found it is beneficial to 3D print, vacuform, and then cast to get 20 parts rather than print something 20 times. There can be so much that goes wrong with a 3D printer and there is a lot to be disillusioned about.”

Who is Interested in FormBox?

Redford claims that they have focused on three voices when planning this project. He explained: “Small craft users, such as Etsy sellers or Facebook sellers; and small businesses; and then hobbyists we aimed for with the Kickstarter campaign and this has proved successful.”

There are many benefits for these groups when it comes to using the Formbox. Redford said: “With certain crafts there is a high barrier of entry as you need to be technically savvy whereas with our machine you can just cut up a potato and put it in the machine and create a vase really quickly. It is really difficult to make custom molds especially if you are trying to keep your costs low, so with our machine you can make your own.”

However Redford has also been surprised by the interest that unexpected groups have shown in the FormBox. He said: “All of these people have suddenly come out of the woodwork including chocolatiers. We went nuts when we realized we had gone viral in cake making Facebook groups,” he laughs. “It was being sent around these groups to show you can make multiple patterns on your cake — we hadn’t considered this at all.”

Mayku Library

The whole project has been developed at the Makerversity in London. Redford explained: “It’s a maker space in central London in the basement of Somerset House, and it’s like one of the only maker spaces in London, if not in central London, that focuses on physical things.”

As well as this physical FormBox, Redford has also developed the Mayku Library which he hopes will greatly benefit designers. He said: “Both Alex and I come from a digital design background so it is incredibly important to us, as without that people aren’t going to know how to vacuform stuff.” He added: “This is where it all begins I guess, and we want to start collaborating with great designers and that will be where the heart and soul of Mayku will be online.”

In order to make sure that the FormBox was usable for everyone, Makerthons were held in order to test out the design. He said: “We wanted using our machine to be as easy as making toast and not just for factories and so the makethons were important for feedback on our products, what changes can we make while we are in design phases and for user testing to make the best experience possible. It is also for building a community. We will be doing much more of those in the future.”

What Can You Make with a FormBox?

The most interesting item Redford has seen created with the FormBox was something a little unusual. He said:”My personal favorite was probably a team at one of the makerthons who made a bees wax banana chandelier. They vacuformed a load of bananas and made two part molds and filled them with bees wax and made a hanging bees banana chandelier.”

For the future it seems that more desktop industrial tools are in the pipeline. Redford said: “There are loads of things that we want to build, like another 10 machines we want to make. The next one is not 100%, but a sheet maker is really exciting as people can start shredding their old plastic and saving the world a little bit which is quite useful.”

When asked what he was most excited about Redford said: “I cant wait to get these things into the hands of people and see what they make.”

If you’d like to find out more, then make sure to visit their Kickstarter campaign page to get in on the action.

License: The text of "Interview with FormBox Creator Benjamin Redford" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.