An Italian student turned 3 old inkjet printers into a €10 DIY 3D printer. Even though it costs next to nothing, it delivers astonishing results.

Inkjet printers are a commodity: You use them for printing flight boarding passes or the first few pages of your discarded novel. If they are broken or a nicer model comes around, most people throw them away.

Italian maker Michele Lizzit doesn’t like to throw away things – he gives them a new purpose. So he created a 3D printer made from old inkjet printers, Amazon cardboard boxes, an old scanner and some hand-soldered electronics. The result is by no means beautiful. But it is a recycled, working 3D printer which costs just €10 to build.

Lizzit is just 18-years-old and a student at Liceo Scientifico Copernico in Udine, Italy. In the name of science, up-cycling, and curiosity, he broke apart three old inkjet printers and a flatbed scanner. He then had enough recycled components to get to work on a new 3D printer.

Check out the final printer’s test print in the video below:

Trash Your Home Office and Create a Cheap 3D Printer

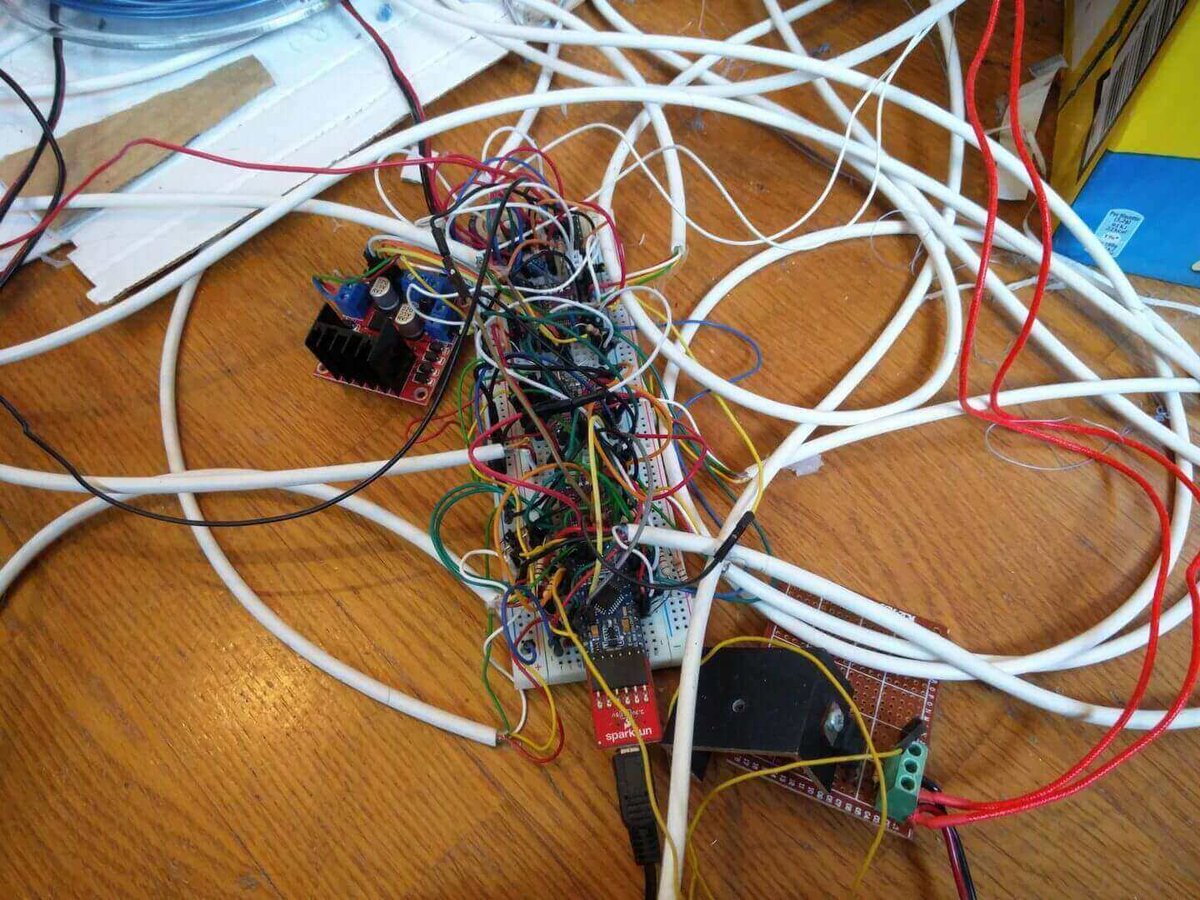

To build a functioning printer, Lizzit only had to buy a hotend extruder and some electronics, all in all for €10. As well as this, he used an ATmega328 processing brain, a motor driver, three driver boards and a high-current transistor.

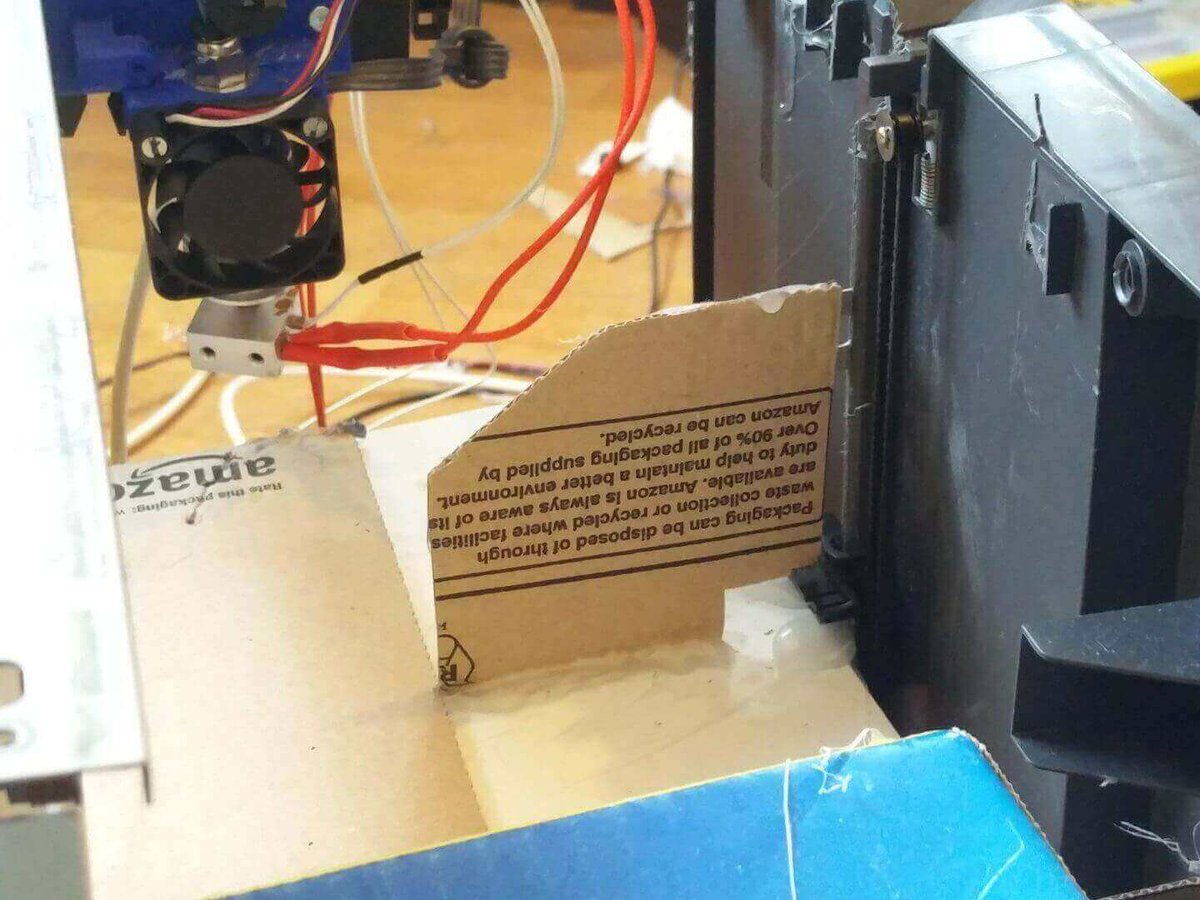

After procuring everything he needed, assembly included 3D printing an extruder housing and getting to work on repurposing old parts. He used two cardboard boxes as a printer frame, and then fixed the axis on them. As well as this, rather than buy a new hobbed bolt, he used an inkjet printer paper loading mechanism.

He explains: “The procedure to build the Z axis then varies greatly depending on the scanner you have. What I did is to take the plastic plate that covers the scanner and attach it to the “movable” part of the scanner, then I have covered it with a sheet of thick cardboard that protects the plastic plate from the heat and offers great adhesion for prints.”

Although the printer doesn’t look particularly professional, with cardboard biscuit boxes supporting the frame, it works. Now, Lizzit hopes to create a solid metal frame to make printing more precise.

However, he explains that the printer can achieve a print resolution of 33 microns on both axes. If you’d like to have a go yourself, check out the open source system firmware created by Lizzit. You can find out more about Lizzit’s process and follow his instructions on his website.

Don’t fancy breaking apart equipment in your office? Instead, why not check out All3DP’s list of cheap 3D printers, here? They won’t cost you €10, but they’ll help avoid an argument with your boss.

Source: New Atlas

License: The text of "Italian Student Builds a €10 3D Printer from Old Inkjet Printers and 3D Scanner" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.