3D printing is being used to recreate the past in the form of fossils. A British paleobiologist now offers a free library of 3D printed fossils for anyone.

Dr. Roger Close, a Postdoctoral Research Associate and vertebrate paleobiologist at Oxford University’s Department of Earth Sciences, brought together his knowledge of 3D printing and his studies in ‘macroevolutionary’ patterns in fossil records.

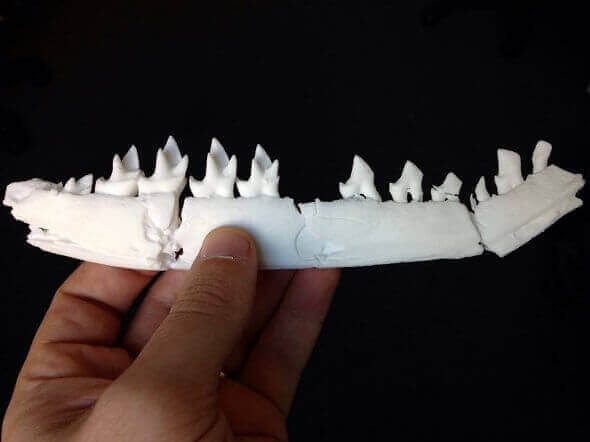

With some colleagues, Roger published a paper reporting the discovery of this 170-million-year-old fossil. He states that Palaeoxonodon is an important species for understanding the evolution of molar teeth in modern mammals.

The team of researchers used 3D printing and 3D scanning to help find out that three species previously described on the basis of individual fossilized teeth actually might only belong to just one species.

How Can 3D Printed Fossils Help?

3D printed fossils have many benefits such as the ability to scale up the fossil meaning it is more easily observed. Roger told i.materialise: “The fact that the model could so easily be scaled up to 20 times its original size made it all the more fun. I found that being able to scrutinize a 3D print was genuinely helpful while describing the anatomy of the fossil for publication, as it highlights features that might not be immediately apparent on a computer-screen rendering.”

Another brilliant advantage of 3D files is that they can be shared. With this technology, researchers, educators, and hobbyists from all over the world can now download, edit, rescale, and 3D print the jaw.

Roger said: “As recently as ten years ago it would have been standard practice to expend a considerable amount of time and effort manually removing the fossil from the hard limestone rock. However, we were able to use an X-Ray Computed Tomography (CT) scanner at the Natural History Museum in London to obtain an amazingly detailed three-dimensional image of the specimen, so all the preparation could be done digitally.”

From here, Roger created a 3D surface file from the scan and was then able to order a 3D print from i.materialise.

If you’re interested in checking out this recent discovery, you can visit the files which Roger uploaded to DataDryad.org!

License: The text of "3D Printed Fossils can be Printed and Shared" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.