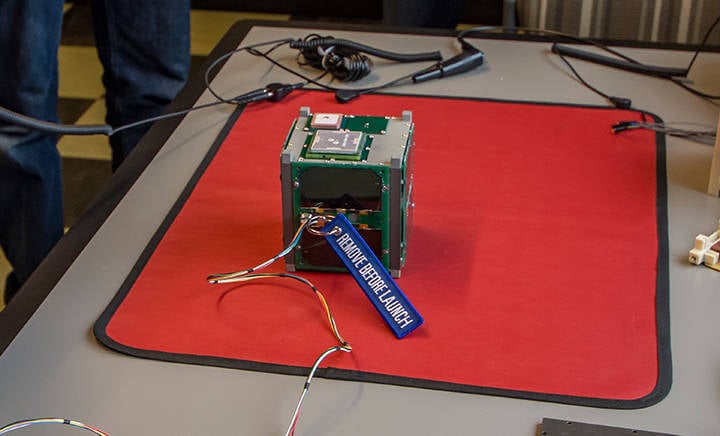

A rocket launch this week will see a CubeSat, designed by students, reach space and collect data on how harsh conditions effect 3D printed materials.

Ever heard of a “CubeSat”? This NASA program deploys (relatively) cheap, small satellites in earth‘s orbit – just think of it as ”lab experiments in space”. One of these small satellites, which will launch on November 10th aboard a Delta II rocket this Friday from Vandenberg Air Force Base, is the “MakerSat-0”. It‘s one of the four satellites of the ELaNa XIV mission.

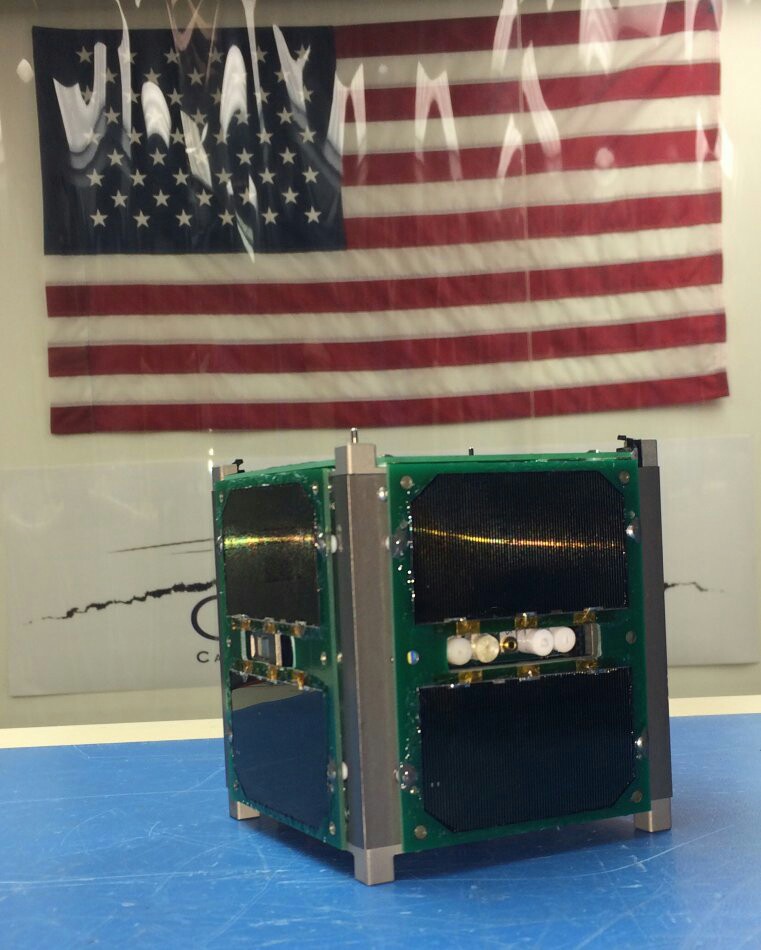

The MakerSat-0 was built by students from Northwest Nazarene University (NNU) and Caldwell High School in Idaho. Its purpose is to collect real-time data on the effects of space on 3D printed polymer materials.

MakerSat-0 will test ABS, PLA, nylon and PEI/PC ULTEM half-gram samples.

The students worked with Made in Space to create the CubeSat. Their design will be carrying electronics to help collect test data continually for the next few years.

“This is the first of two MakerSat missions that we’re launching in partnership with Made In Space… The MakerSat missions will provide the space community with invaluable test data on how these materials react to oxygen plasma, ultraviolet and ionizing radiation, vacuum, extreme temperatures, and micrometeorite collisions,” said Dr. Stephen Parke, NNU engineering professor, and faculty lead.

MakerSat-0 Will Test the Effects of Space on 3D Printing Filament

Radiation, vacuum, extreme temperatures, micrometeorite collisions – these are the effects the MakerSat-0 will have to handle. Even while the CubeSat orbits Earth, the students can access their hard work. After just two hours in space, data will be accessible on Earth. They can do this through their smartphones, making it possible to keep up to date with the data.

Meanwhile, the MakerSat-0 will be flying at an altitude of 800 kilometers. It will also travel at 17,000 mph in a sun-synchronous orbit crossing the North and South Poles. Impressively for us Earth-dwellers, this will happen 14 times a day.

MakerSat-0 will pave the way for MakerSat-1, a CubeSat that will be printed and assembled aboard the ISS, taking advantage of the weightless environment.

The results are of importance for manufacturing in space. “Our AMF printer makes it possible to manufacture and assemble CubeSats on demand aboard the ISS. Using AMF, universities, government and company researchers can rapidly design, print, test, and iterate new research concepts at a much lower cost than traditional research methods on Earth. The MakerSat missions are going to provide us with materials research information that will be used for projects such as Archinaut, the first in-space, autonomous robotic additive manufacturing and assembly platform,” said Matt Napoli, Made in Space vice president of In-Space Operations.

Source: Press Release

License: The text of "Once Launched in Space, MakerSat-0 Will Collect Data on 3D Printing Materials" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.