In an effort to improve the industrial usefulness of 3D printing steel, Lawrence Livermore National Laboratory has developed a process that yields stronger steel than current methods.

Lawrence Livermore National Laboratory is at it again. Not content with printing aerospace carbon-fiber composites, glass at room temperature and large-format metal prints, another team from the never-resting R&D lab, along with collaborators from Ames National Laboratory, Georgia Tech and Arizona State Universities has turned its considerable additive manufacturing expertise on furthering one of metal 3D printing’s greatest issues. Steel.

Steel is a great metal, used for more applications that you can shake a metal stick at. An alloy of iron, carbon and myriad other metals, it exhibits desirable chemical and mechanical properties that have made it a go-to metal for many industries.

Trouble is, it is generally terrible for 3D printing, losing some of the characteristics that make it special. The ‘secret sauce’ of steel’s success lies in its structure. Centuries of metallurgy have lead to a combination of steps in its production that give it a cell-like structure.

Boundaries exist between ‘grains’ of alloy in the material which, when strong enough, make the metal tough yet ductile enough to form into useful shapes. Formed by the intense heating the metal undergoes in its making, current laser sintering 3D printing processes cannot recreate this fracture-dampening strength.

3D Printing Better Steel

When you attempt to use steel in current metal 3D printing processes, typically laser sintering, the resulting solid is porous. Generally this means vastly weaker bonding holding the whole thing together, when compared to traditionally forged steel. The parts are strong, but have little of the ductility that makes steel so useful.

A report from the collaboration focuses on the 3D printing of 316L steel, a common marine-grade steel favored for its chemical resistance. This particular variant of steel traditionally exhibits both strength and ductility, and this new research may well have unlocked a path to printing it without the expected trade-off of ductility.

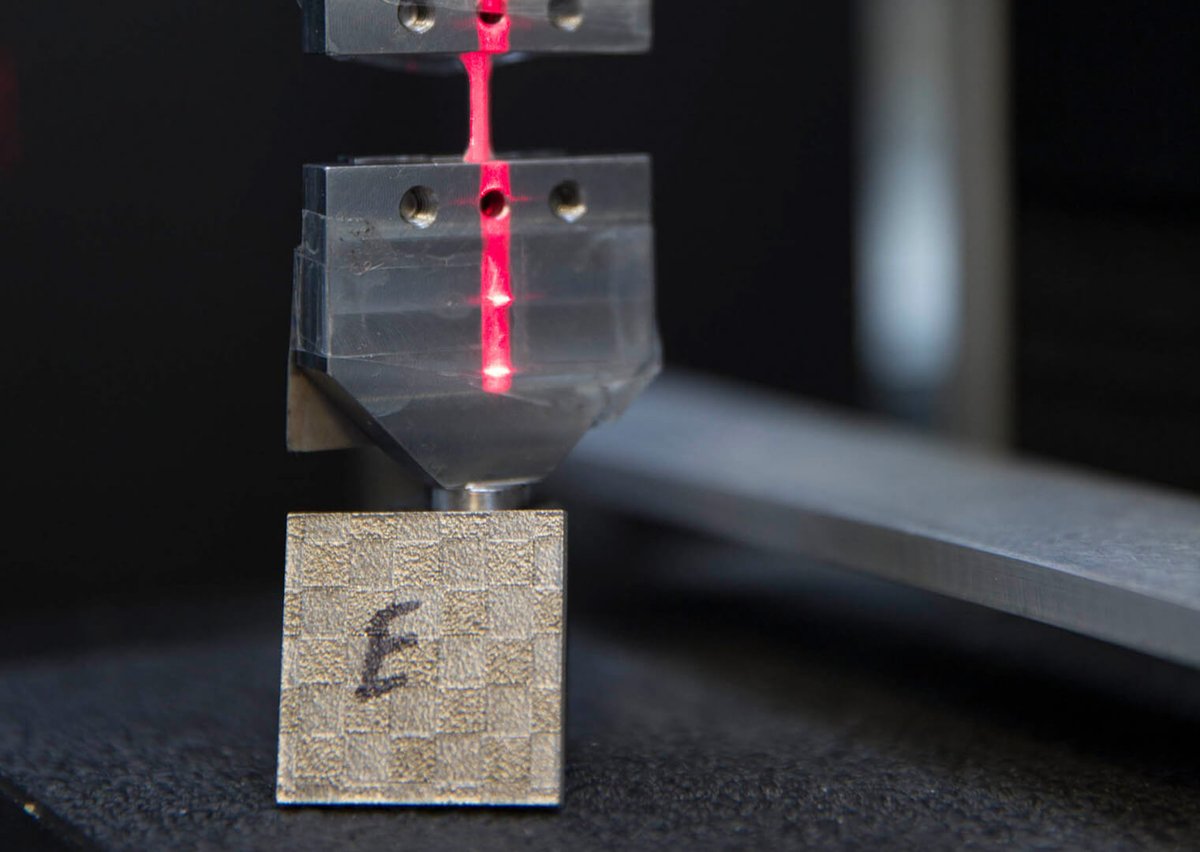

Using a regular metal laser sintering machine, the researchers added a computer control in place to monitor and alter the rapid heating and fusing of the metal powder. With precise control of this they were able to manipulate the growth of grains with strong boundaries. Similar to, and at times exceeding those formed naturally in traditional forging, the result is 3D printed 316L steel with both strength and ductility.

The report, Additively manufactured hierarchical stainless steels with high strength and ductility, is available to read over at Nature Materials.

Source: ScienceMag

License: The text of "LLNL Researchers Develop Process to Print Stronger Steel" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.