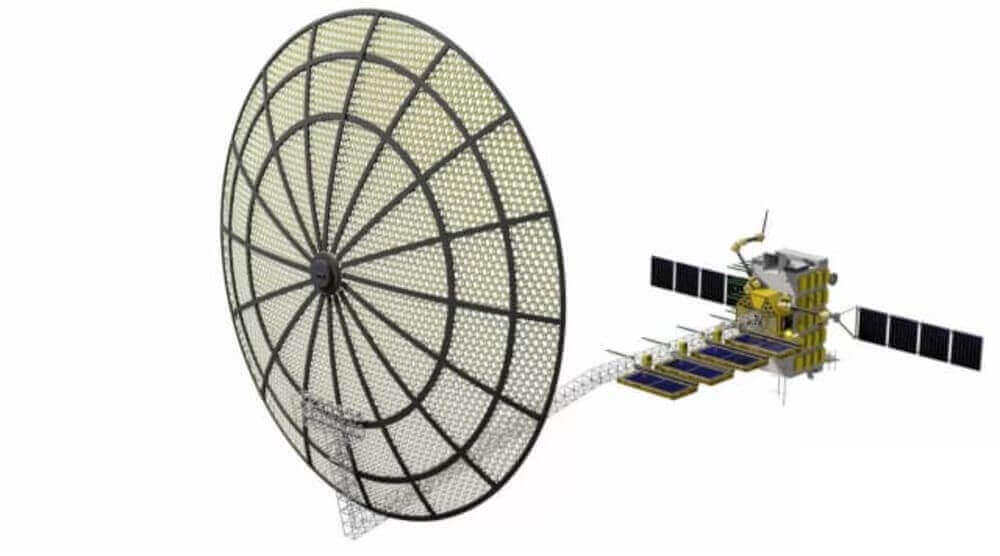

Made in Space has developed and demonstrated a system called Archinaut which uses 3D printing and robotic arms to manufacture in space.

Worried about where humans will live once we’ve blown the planet to smithereens in a hail of nuclear fire? Then you may be glad to know that Made in Space is even closer to additive manufacturing in space. Mars, here we come!

Made In Space has developed and recently demonstrated a system called Archinaut. The aim of the system is to be able to 3D print and assemble large objects in the cold vacuum of space. Examples include solar arrays, satellites and space station modules.

A demonstration here on Earth was recently shown to the public. The system, which is funded by NASA, was able to operate from within a thermal vacuum chamber.

Made in Space even showed off the technology further by 3D printing a 37-meter-long structure. Made in Space CEO Andrew Rush, explains:

“These successful demonstrations mean that on-demand, adaptable manufacturing of complex structures in space has been significantly derisked. This expands the design space. We hope that mission planners can now more confidently design missions around in-space manufacturing and assembly, optimizing satellites for their operational environment, not just launch.”

The company already has two small 3D printers installed on the International Space Station (ISS). But the Archinaut project, which is essentially a huge 3D printer with robotic arms, would add a radical new dimension to their capabilities.

https://youtu.be/e2N1i7_13QM

Could Archinaut Foster Close Encounters of the Third Kind?

There are many huge benefits which come with being able to manufacture in space. For example, it’ll be possible to print large telescopes which are too big to launch. Dreaming bigger, could it lead us to finding life on other planets?

More realistically, it’ll definitely be possible to create better tools on demand. To do this, the system works by 3D printing large parts and then attaching them together with the robotic arms.

Perhaps this will also be how we create new homes in space. Or so Rush suggests anyway. He adds:

“Satellites incorporating in-space manufacturing and assembly will inherently be more capable and provide more value to operators and users. We’re proud to be making this vision a reality and grateful for NASA’s support.”

It’s all very exciting. But the company estimates that it’s going to take at least three years before they’re ready to launch a small satellite and fabricate/assemble a large structure in space. Let’s hope the planet Earth can hold on until then.

Source: Mercury News

License: The text of "Made in Space Take a Giant Leap with New Archinaut System" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.