Your small business needs top quality 3D-printed objects to sell. Here’s how to ensure your customers will get the best possible service.

As a small business or entrepreneur offering 3D printed objects, you know how important it is to keep your customers engaged. Providing them with bespoke and unique designs is one thing, but you can’t leave anything else to chance, like a backlog of orders or a broken down printer.

Follow these 8 tips for better 3D printing, so you can maintain your investment and stay ahead of the competition. By doing so, you’re going to save yourself a lot of time and effort, and put yourself in a better position to appeal to new customers and encourage repeat business.

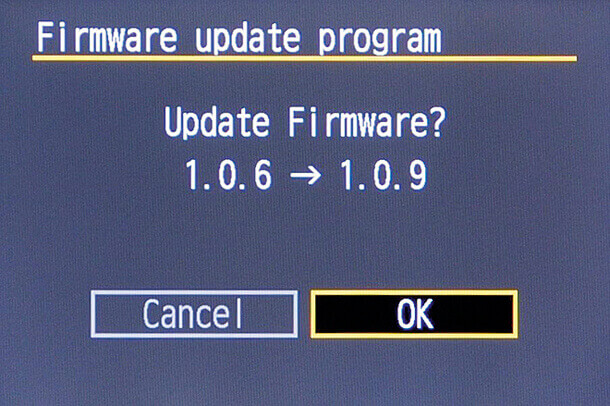

1. Keep the printer’s firmware up to date

Make no mistake, keeping the printer’s firmware up to date is absolutely essential.

Firmware updates provide the latest software and features for your 3D printer, and you’ll be able to print the highest quality items available. Whilst other small business rivals are busy updating their fleet of printers, you can relax and focus on your customers.

To update the firmware on your 3D printer, check the website of your manufacturer daily for announcements. Alternatively, if your 3D printer is wifi enabled, it should have an option to automagically download and install firmware updates from the cloud.

If you follow only one piece of advice on this list, make sure it’s this one.

2. Make sure you have the right filament for the job

Ah, filament. To paraphrase Homer Simpson, it’s often the cause of — and solution to — all of your 3D printing problems.

Prior to loading the material into your printer, unwind the spool a little to check for any knots and kinks. Just like a 2D printer, foreign objects will cause the machine to jam. If this happens in the middle of printing, a small business will lose valuable production time. It doesn’t hurt to do a quick check before the start of each job.

It sounds obvious, but try to follow the manufacturer’s directions for the best type of filament to use with the 3D printer you own. Not all printers, for example, will play nice with ABS filament.

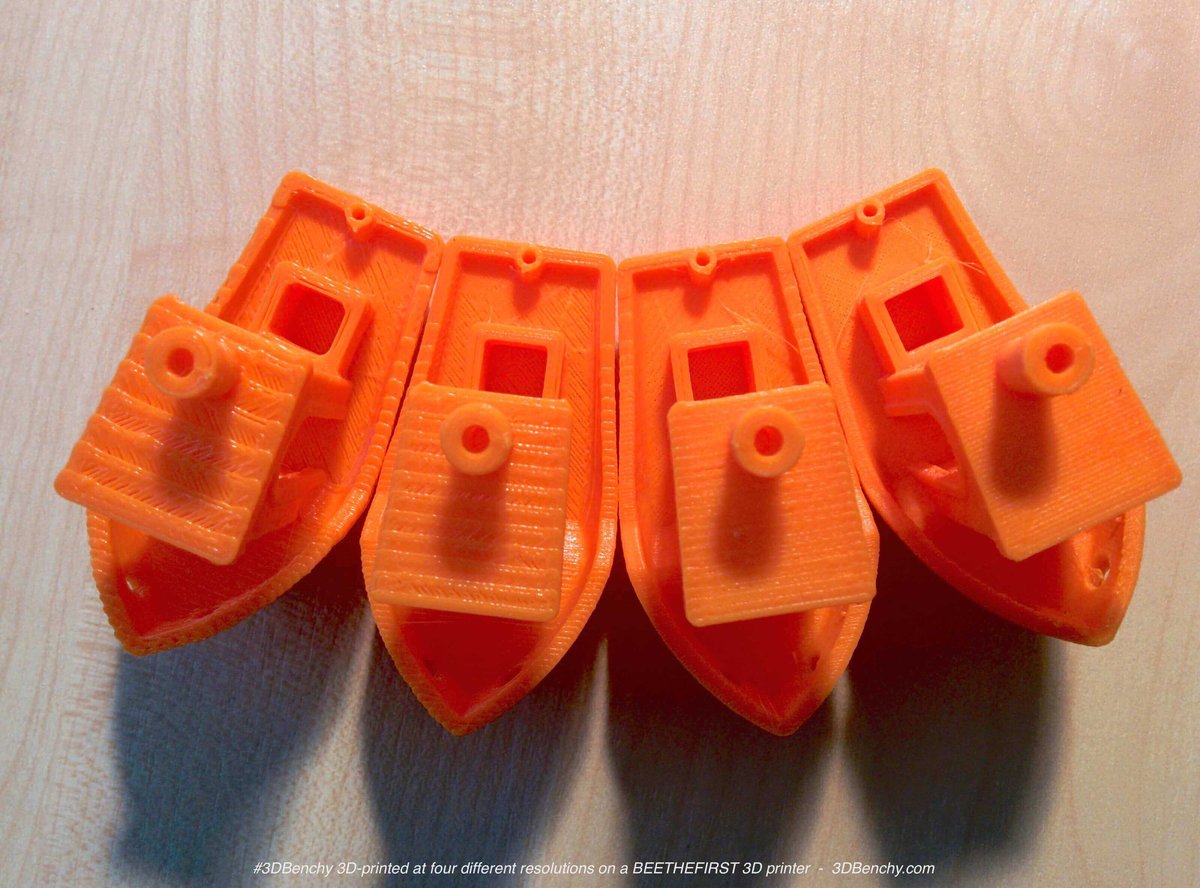

3. Printing in standard resolution is the sweet spot

You may be under the impression that high resolution is the best. Not always!

The higher the resolution of a print job — the thinner the filament layers – the longer it will take to complete. And when you factor in a medium sized object for printing, you’re looking at a turnaround time of 24 hours or more.

Conversely, the lower the print resolution (and the smaller the object), the quicker you can move from one job to the next. Standard resolution is the perfect midway point, giving your small business the quality you need at speeds that help you keep up with customer demand.

4. Swap out different colours while the print is paused

More expensive 3D printers can print in more than 2 colours. But your small business can print in extra colours without extra cost.

If the job is a single piece print, here’s what you do. Pause your project in the middle of a print, and then swap out the filament for a different colour. Then resume printing and — hey presto — you have multiple colours. This trick can be repeated as often as your patience allows!

Another tactic is to print separate parts in different colours, for example the limbs of an articulated doll, and then assemble the finished model.

5. Put together a 3D printing tool kit

You’re a professional maker, so you’re got to have the right tools for the job.

In your workshop or workspace, put together a kitbag that includes a spatula, needle-nose pliers, and a sharp plastic object to scoop, shape, and remove extra bits and pieces from your 3D printed items.

And even if your 3D printer has a heated print bed, sometimes it’s worth using a gentle adhesive like hairspray to ensure the first layer of the print always bonds to the build plate.

Alternatively, add a “raft” to the underside of the print job — a removable layer of plastic – to make it totally foolproof.

6. Sand and paint objects to give them a signature look

Your small business can add a personal touch to 3D printed objects by paying close attention to the details.

Once a print job is complete, there’s still a lot of “post-production” work that can be done. Gently sand items to remove any rogue strands of filament, or use acetone to give the object a smooth finish. You can even custom paint it to the customer’s liking.

These extra steps will surprise and delight your customers, especially when it comes to 3D printed figurines of people and pets.

7. Create custom print profiles for your small business

Not all print jobs are the same, so tinker with the print profiles to produce the best result.

All 3D printers offer you a “good, better, best” option for print settings. This is great in the early stages of your small business, but you can also do a deep dive into the settings to create your own custom print profiles, and save them for later use.

This is especially useful for repeat customers who have specific requirements for their print jobs. Or if you want to experiment with individual models to produce the optimum build.

8. Have your printer ready for your next project

You never know when that phone’s going to ring, or your email inbox is going to ping. Your small business should be prepared to start on each new project quickly and easily.

Be ready to move at a moment’s notice by leaving filament in your machine and having a clear build plate. This is especially important if using a mobile device to manage and activate your print job remotely.

It’s helpful if someone is in the vicinity of the printer — or if you have a remote camera set-up — to help verify that everything is running smoothly. And that a fresh print job hasn’t started on top of another!

Economics 101: Desktop 3D Printing

Follow the tips listed above and soon you’ll be 3D printing like an expert. It’s all about the details and giving your customers what they want. Taking a great service and making it better is how the best small businesses become successful.

Finally, if you’re interested in learning about more advanced techniques for small businesses, download this free white paper from MakerBot Europe, Economics 101: Desktop 3D Printing. It has useful case studies on real-time prototyping as a way to reduce costs and streamline design cycles.

License: The text of "Running a Small Business? 8 Maintenance Tips for your 3D Printer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.