MakerBot has unveiled the new MinFill feature for MakerBot Print, enabling minimized infill for faster prints while using less material.

Not all innovative 3D printing enhancements must come in the form of hardware. MakerBot has managed to increase print speeds and minimize filament use by introducing MinFill to their MakerBot Print software.

This new dynamic Print Mode feature is integrated within the company’s 3D printing slicer software. Many projects require surface quality and print speed, but don’t always necessitate durability and density.

In these specific cases, MinFill is the option that the MakerBot community has been waiting for.

MakerBot Print’s MinFill Mode Saves Time And Materials

https://www.youtube.com/watch?v=-NAnRr-33UE

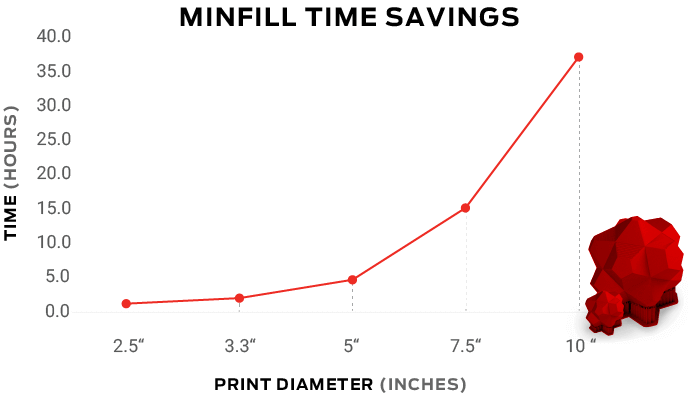

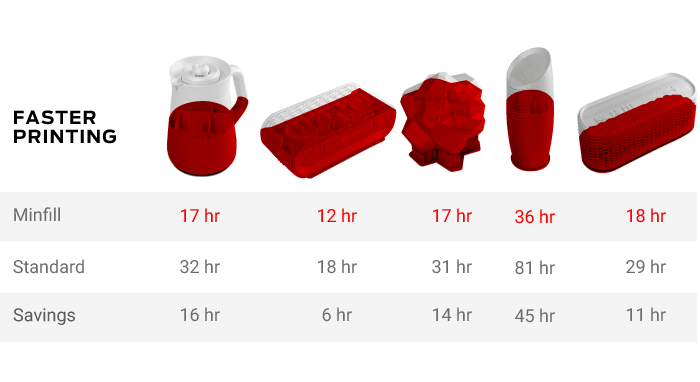

The latest MakerBot Print feature uses an algorithm to determine the bare minimum of infill and support needed to properly 3D print an object. MinFill typically increases print speeds by 30 percent, while also cutting filament use by 30 percent.

These advantages almost triple when it comes to more high-volume models, which print at up to 80 percent of the normal speed. For professional users, this improves concept modeling capabilities, while also allowing more iterations to be produced.

The new feature also offers advantages for educators, who can teach students in a more timely pace while also saving on material costs. MinFill is compatible with the MakerBot Replicator+, Replicator (5th Gen), and the Replicator Z18.

How Does This Algorithm Work?

And so, the MakerBot software team developed a way to eliminate infill when it’s not needed. The new feature works using an intelligent slicer algorithm, automatically streamlining and reducing support structures.

3D models are automatically analyzed by the algorithm, generating the least amount of infill possible for each print. MinFill focuses on the shape, placement, and density of the supports, onladding them to areas like roofs or certain wall types.

If the print necessitates no internal structures, than MinFill ensures that none will be printed. The MakerBot Print feature always takes surface quality into account, ensuring that the aesthetic of your print is never compromised.

According to MakerBot, MinFill is the only solution that automatically adapts to all geometries without the need to manual adjust the software. By providing increased speeds and reduced material use, MakerBot is improving the functionality of their 3D printers through software enhancements.

Source: MakerBot

License: The text of "MakerBot MinFill Offers Faster Prints With Less Filament" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.