Most popular

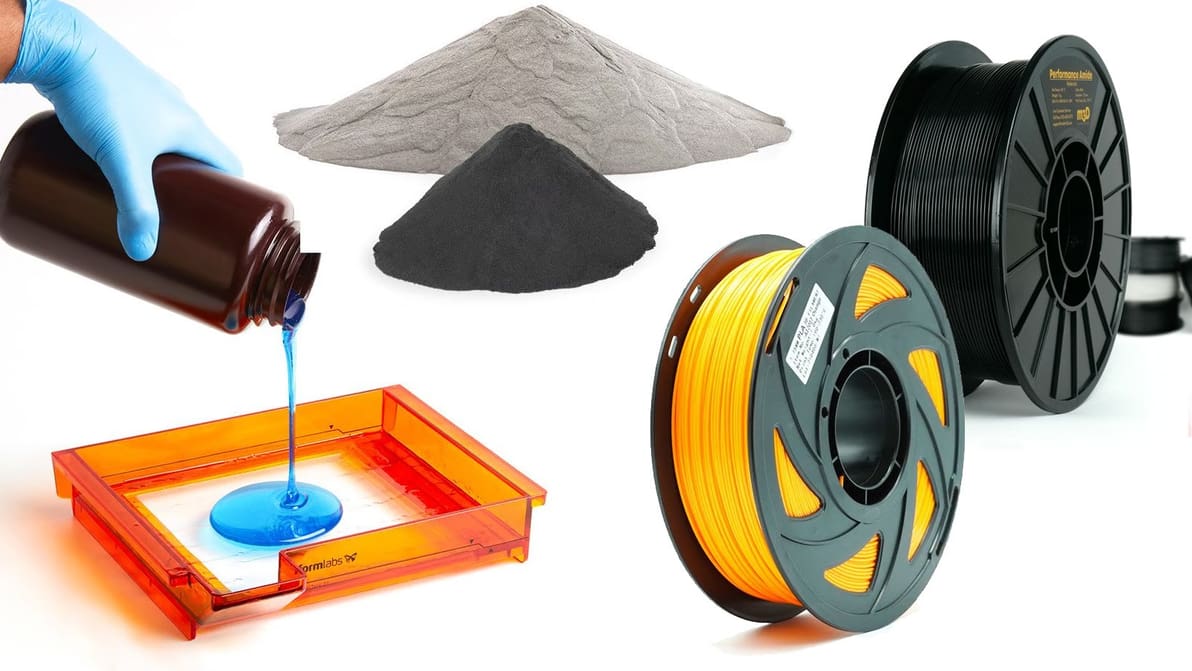

There are thousands of materials used in 3D printing. In this guide for professionals and hobbyists, we cover everything that’s fit to 3D print with.

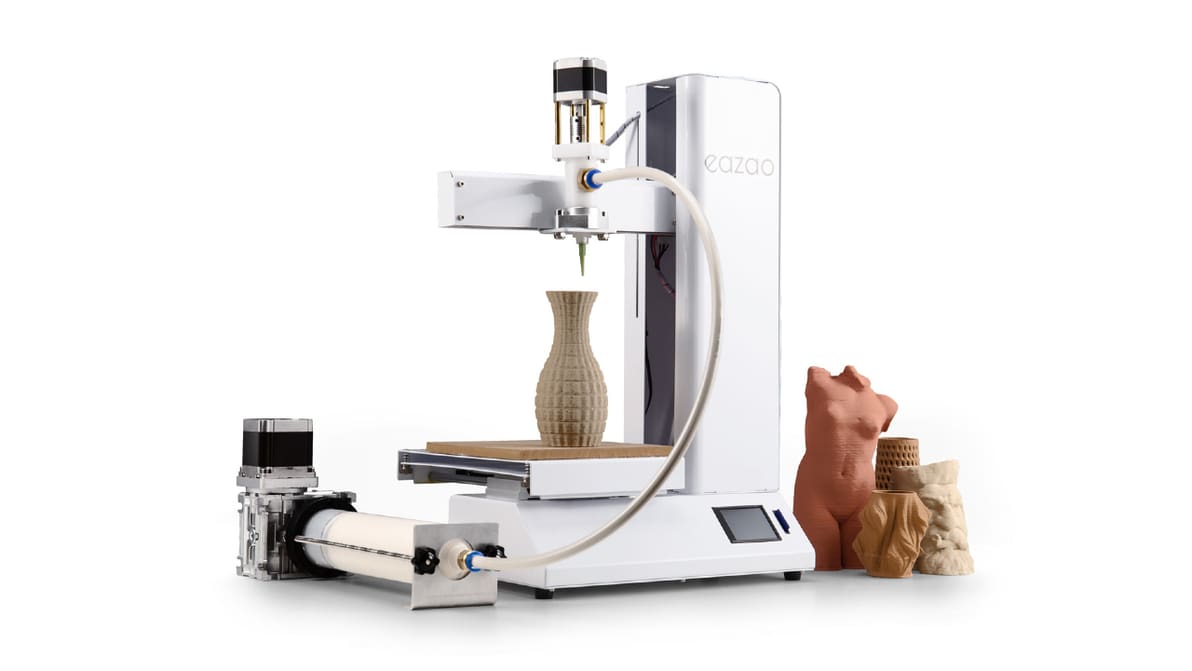

Pioneering researcher Julian Jauk explores the uses of 3D printed clay and why it’s the more sustainable building choice.

New “green medal” environmental prize at world-renown show goes to low-carbon footprint garden with 3D printed terracotta planters.

Discover the strongest 3D printing materials and how to pick the right one for your 3D printing project.

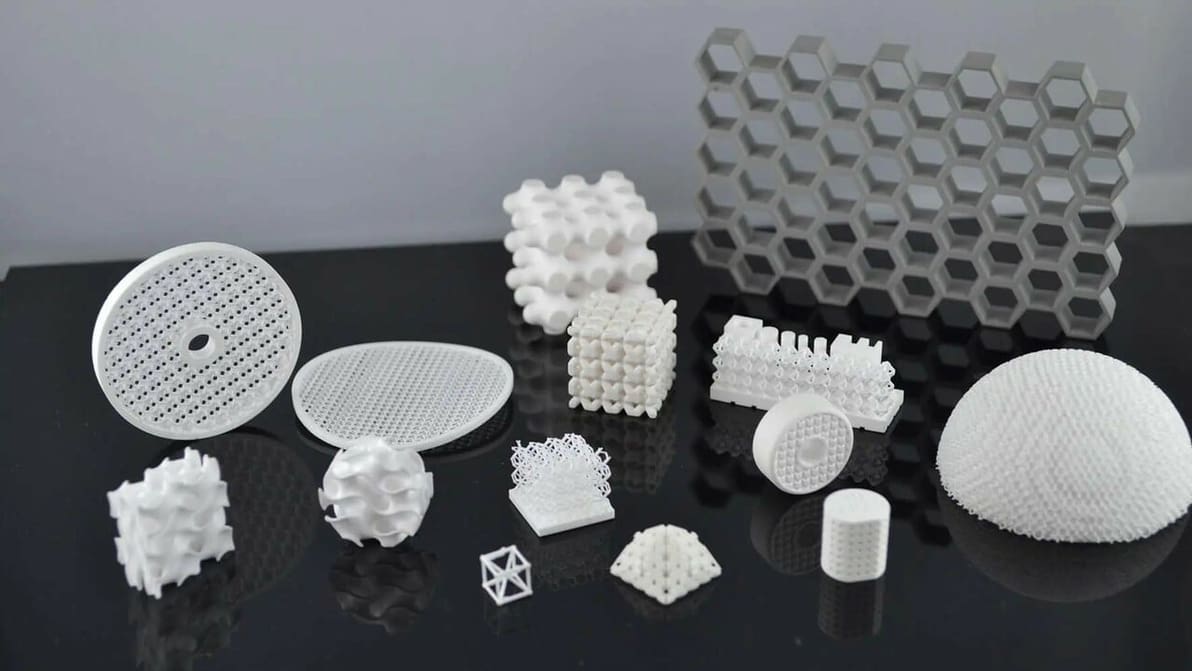

Learn why vat photopolymerization is the most advanced 3D printing method for technical ceramic materials used for more parts today than ever.

Deepen your understanding of technical ceramics and why 3D printing is the fasting growing method of manufacturing ceramic parts and products.

A new VoxelMatters report finds 3D printers that print technical ceramics have matured greatly over the years along with the available range of materials, so why is industry uptake so slow?

Print larger and series production ceramic parts with the new CeraFab System S320 vat polymerization 3D printer from Lithoz.

With software to network Lithoz ceramic 3D printers located at service bureaus around the globe, you have access to your own ceramic part factory.

Smashed your coffee mug? You may soon be able to print a new one if the Cerambot Eazao Kickstarter gets off the ground. The hottest thing about it? The microwavable kiln that hits over 800 ℃.