The California startup Relativity Space Inc. is building rockets at a faster and more affordable rate using only gigantic 3D printers.

With forward-thinking innovators like Elon Musk determined to send humans to Mars in the imminent future, the aerospace industry has been wholly focused on finding more affordable production methods to build rockets. In this space, 3D printing technology has emerged as a valuable tool for rocket engine components and prototyping, used by the likes of NASA, MIT, and many others.

One of the brightest young stars in the aerospace industry’s sky, the Los Angeles startup Relativity Space Inc. is going all-in on additive manufacturing. Over the last two years, aerospace engineers Tim Ellis and Jordan Noone have been building their own gigantic printers to manufacture entire rockets.

Both men have amassed experience with some of the most space-savvy company’s in the world; Ellis with Blue Origin and Noone with SpaceX. Together, they eventually decided to team up and find a way to reduce the cost of rocket launches. Currently, a rocket launch costs about $100 million, but Relativity Space wants to bring this exuberant price down to $10 million over the next four years.

To ensure that their production process was cheaper and faster than other methods, the duo set out to build their own 3D printers from scratch.

Relativity Space Thinks 3D Printing is the Key to Reducing Rocket Launch Costs

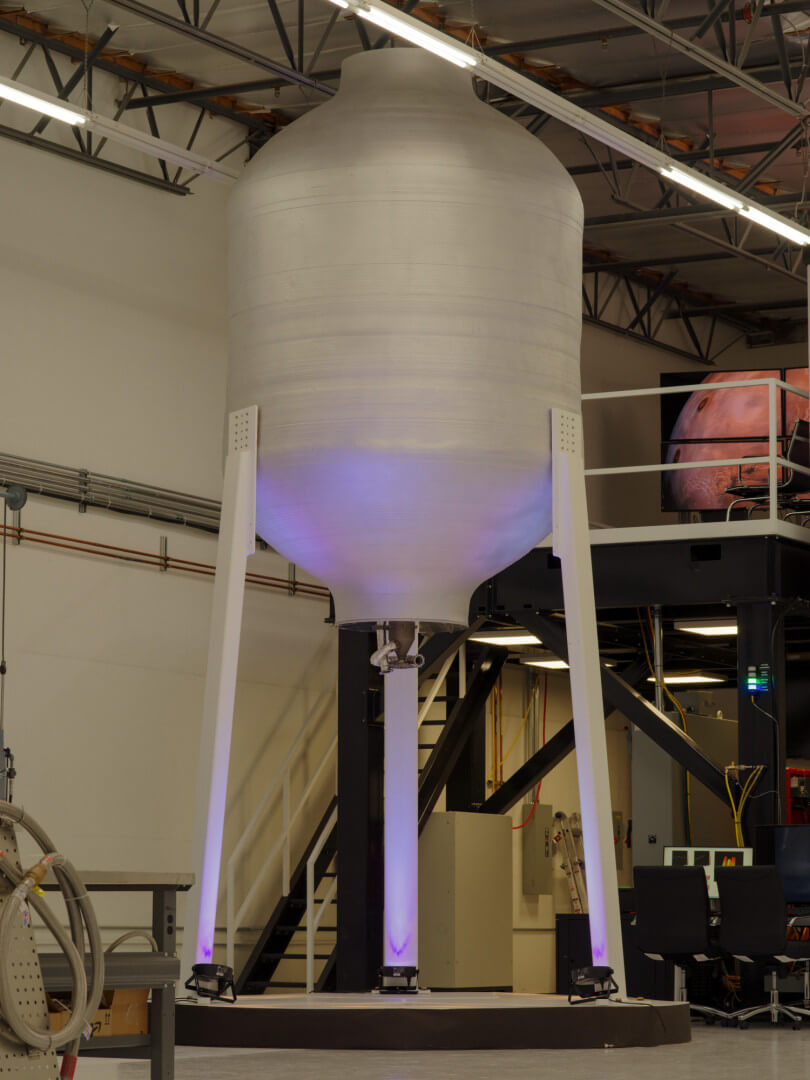

These machines include 18-foot-tall robotic arms that are equipped with lasers that melt aluminum wire into a specified shape. According to Ellis and Noone, these robotic arms work in tandem with custom software to create the rocket’s entire body in a single print.

Although they’ve yet to complete the task of printing an entire rocket, Relativity Space did manage to build a 7-foot-wide and 14-foot-tall fuel tank in just a matter of days. The team also 3D printed a rocket engine in a little over a week.

“The space shuttle had 2.5 million moving parts. We think SpaceX and Blue Origin have gotten that down to maybe 100,000 moving parts per rocket. We want to get to 1,000 moving parts, fewer than a car,” said Ellis.

Sometime around the year 2020, the startup is planning to 3D print a 90-foot-tall, 7-foot-wide rocket that can carry 2,000 pounds to orbit. If successful, the two co-founders claim that the rocket will launch in 2021.

At the moment, Relativity Space has 14 full-time employees and is operating with $10 million in funding. Investors include entrepreneur Mark Cuban, the venture firm Social Capital, and startup accelerator Y Combinator.

Although Relativity Space may not have ingenious billionaires like Musk (SpaceX) or Jeff Bezos (Blue Origin) at the helm, their plan to reimagine the entire manufacturing process of rockets puts them in a league of their own. Additionally, the company hopes to refine its 3D printers to make them durable and adaptable enough to construct a space colony on Mars.

“If you think that type of future is inevitable, then we will need lightweight, intelligent, and automated manufacturing to build stuff on another planet. Our long-term mission is to print the first rocket on Mars,” Ellis says.

Source: Bloomberg

License: The text of "Meet the Aerospace Engineers Using Giant 3D Printers to Create Rockets" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.