A team of researchers from MIT CSAIL have developed ColorFab, a technique that enables the creation of 3D printed objects that change color after production. This process could be integrated into the fashion and jewelry industry, and would help promote waste reduction.

For design and fashion creatives, the long-standing desire to change object color on the go may have just come true. A team at the Massachusetts Institute of Technology’s Computer Science and Artificial Intelligence Laboratory (CSAIL) is developing a technique to allow 3D printed objects to change colors after they have been printed.

Called ColorFab, the new technique could eventually be used to 3D print fashion accessories or home décor which have the ability to switch color to match the user’s needs or desires. Think about the awe-inspiring and colorful nature of the classic mood ring, but applied on a much larger scale.

The process is based on a custom-developed ink that combines a base dye with a photochromic (i.e. light-adaptable) dye. Under exposure of UV light, the photochromic dye can elevate the color of a base dye. Simultaneously, other colors disappear from exposure to visible light ranges.

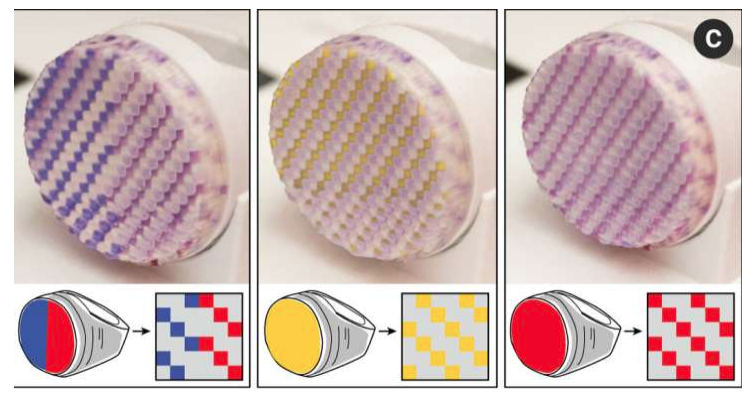

The MIT research team uses a UV light to change the pixels on an object from transparent to colored. All the while, an office projector with visible light ranges works in tandem to turn other pixels transparent.

These findings were detailed in a paper called ColorFab: Recoloring 3D Printed Objects using Photochromic Inks, co-authored by MIT Professor Stephanie Mueller, postdoc Parinya Punpongsanon, undergraduate Xin Wen, and researcher David Kim.

Although the ColorFab platform comes from bright minds at MIT, using the color-changing technique is actually quite simple. First, a 3D designer must upload his or her 3D model to the ColorFab interface. From there, they can then select the desired color pattern for their 3D printed object.

The color swapping is based on a grid-like design. Designers just need decide which pixels they would like to activate and deactivate.

MIT’s ColorFab Platform Aims to Address Waste Problem in Fashion Industry

According to testing by MIT CSAIL, it takes around 23 minutes for a 3D printed part to switch colors. The researchers tested the ColorFab platform on three criteria: coloring time, precision, and how quickly the color decayed.

However, in the future, the team is aiming to shorten this time to just a few minutes by using stronger lights and more photochromic dyes. They also hope to make the color less grainy by activating the colors on an object more closely together.

“Appearance adaptivity in general is always a superior feature to have, and we’ve seen many other kinds of adaptivity enabled with manufactured objects. This work is a true breakthrough in being able to change the color of objects without repainting them,” says Changxi Zheng, associate professor at Columbia University.

Although switching the colors of objects and fashion items sounds like fun, the researchers at MIT have a more righteous goal in mind – waste reduction. The team hopes that more adaptable clothing and accessories will lessen the number of products that one would purchase and subsequently throw away later on.

“Largely speaking, people are consuming a lot more now than twenty years ago, and they’re creating a lot of waste. By changing an object’s color, you don’t have to create a whole new object every time,” says Mueller.

As they continue to refine the method, researchers believe that ColorFab could be adapted for the fashion industry. As a side project, the team is also working on secondary color hues to integrate within the ColorFab platform.

Still in its early stages of development, MIT CSAIL will continue to work on the ColorFab platform, using 3D printing technology to make the clothes and accessories we wear more sustainable and vibrant than ever.

Source: MIT CSAIL

License: The text of "MIT Researchers Develop ColorFab: A Color-Changing 3D Printing Process Like No Other" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.