Researchers from MIT’s CSAIL lab have developed the Foundry system. It breaks down the complexity of 3D printing with multiple materials.

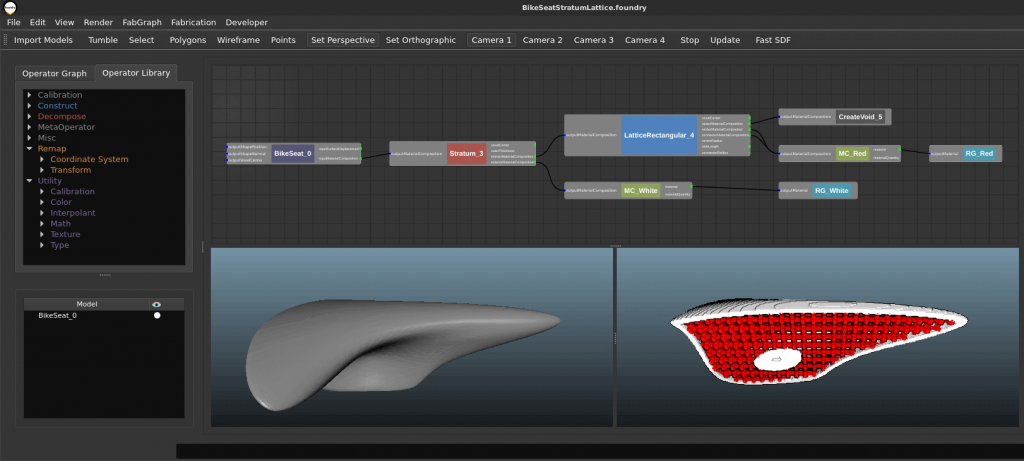

Foundry is a new software package from MIT’s Computer Science and Artificial Intelligence Lab (CSAIL). It’s made for custom-designing a variety of 3-D printed objects. It‘s fast, allows for procedural approach and can even handle multiple materials – and it could become the “Photoshop” of 3D printing.

What’s useful about the software is that it breaks down the complexity of designing a multi-material 3D printed model. MIT’s CSAIL has created the interface to be usable for everyone, not just programmers.

Kiril Vidimče, first author on the paper that presented Foundry and an MIT PhD student, told Design News:

“Even though there are some generative tools out there (e.g., ones that produce lattice geometries), there are no design tools that output material compositions,” said Vidimče. “As such, if you wanted to produce a part that, for example, varies in elasticity along its length, there are no tools to design such behavior.”

Check out the video below to get a feel for Foundry and its uses:

Foundry is a Photoshop for 3D Materials

Although there are already multi-material systems, Foundry offers true multi-material additive manufacturing processes. This means the final part is designed and manufactured using 3D printing.

The software’s high resolution could mean new additive manufacturing capabilities could be realized. For example, creating parts with differing material properties.

Vidimče explains:

“In general, spatially-varying materials allow a paradigm shift in product design. Instead of selecting a particular material from a catalog based on its known mechanical or thermal properties, a designer can precisely specify the required properties in a continuous space.”

MIT use the software with their MultiFab printer. However, Vidimče points out that Foundry can be used with any commercially available multi-material printer. As he points out, the software is the “Photoshop for 3D materials.”

However, the technology is best used for creating 3D printed end-use parts. A design created with Foundry will not be manufacturable using traditional manufacturing processes.

The researchers are still improving and tweaking the software. They hope that in the future, Foundry can be integrated into existing CAD programs, seamlessly interweaving geometry design. Currently, designs must be imported from CAD software before the final material composition can be chosen.

Source: Design News

License: The text of "Could MIT’s Foundry Interface be the Photoshop of 3D Printing?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.