MUN MED 3D is the first 3D printing biomedical laboratory housed at the Health Science Centre in St. John’s, Newfoundland and Labrador, Canada. Its founders have some tips for how others can create their own.

Michael Bartellas and Stephen Ryan came up with the idea of a 3D printing laboratory during their time as medical students. The students became interested in how 3D printing was being used in medicine.

In order to learn more, they both bought 3D printers and began printing and designing models for medical use. However, this wasn’t enough and they applied for a grant at their university which supports initiatives that involve teaching.

The students spent months preparing an application and were awarded the funding. With this grant, they could buy an Ultimaker 2+ and LulzBot Taz 6, hire an engineering co-op student and find space in the Health Science Centre in St. John’s.

MUN MED 3D was born and it’s been an unstoppable force since then. To name just a few of their achievements, Bartellas explains to Ultimaker that they’ve now employed three co-op engineers. They’ve also collaborated with ten medical divisions, published scholarly work, and presented research locally and nationally.

Better yet, they’re able to reach out to the local and international communities through teaching, support the STEM curriculum, and also produce prosthetics. That’s not all though, MUN MED 3D has 35 completed or ongoing projects.

Create Your Own 3D Printing Medical Laboratory with Bartellas’ Tips

For anyone interested in creating their own 3D printing medical laboratory, Bartellas has a few tips. Firstly, he suggests you should know about 3D printing before embarking on a project involving the technology.

As well as reading everything you can, Bartellas suggests hands-on action. He explains that he played around with a Micro M3D and a range of software for months. During this time, he learned the important skill of converting CT and MRI scans to 3D renderings.

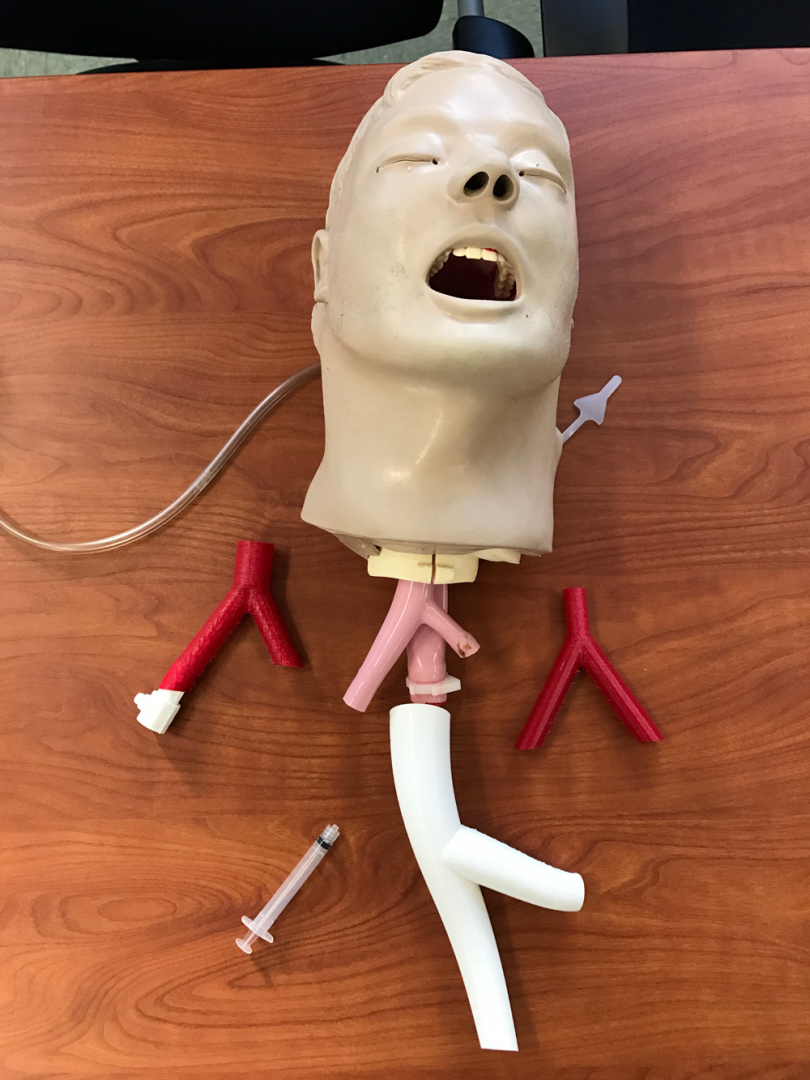

Bartellas suggests that if you’re trying to set up a medical lab with the help of collaborators, having them hold and see how useful the models are in person is a useful factor. Finding and printing relevant medical models is a must.

However, more importantly, perhaps, is finding a mentor who believes in you and your vision. Bartellas also suggests connecting with as many interested people as possible. It doesn’t matter whether they’re engineers, teachers, students or clinicians.

Once the MUN MED 3D lab was set up, prototyping for free ensured people received high-quality finished prints. Bartellas suggests that you budget for this as it’s a useful tool for encouraging people to use the lab.

“Once you have demonstrated your usefulness as a research partner, through high-quality professional work, it will be easier to arrange a cost-sharing strategy for future projects,” he explains.

A few more useful tips include finding solutions and designing prints which are achievable. This helps build trust between yourself and those you’re collaborating with.

Bartellas ends by encouraging you to develop your team and to produce scholarship to get your name out there. The more you do this, the more you’re likely to find funding. Inspired by the MUN MED 3D lab? Find more of Bartellas’ useful tips over on the Ultimaker website.

License: The text of "How MUN MED Set Up a Low-Cost 3D Printing Medical Unit" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.