Here are the 30 finalists in the 3D Printed Habitat Challenge, a NASA competition seeking radical designs for an outpost on Mars.

What could be more exciting than 3D printing? How about the prospect of 3D printing a house? No? Okay, let’s take it step further. How about the prospect of 3D printing a house on Mars, and winning a $25,000 dollar prize for your troubles?

That’s exactly what NASA proposed with their 3D Printed Habitat Challenge earlier this summer. On 10 September they announced the 30 finalists in the contest, and the winner will be chosen at the World Maker Faire in New York on 26/27 September.

Here’s a rundown of the short-listed entries, courtesy of the official gallery from NASA, with accompanying notes from each finalist on the rationale for each design.

What do you think? As a hypothetical Mars colonist, would any of these habitats look inviting to you?

1) The Martian Vault / Tomasz Dzieduszynski

“If it works, don’t change it!” – this famous quote, frequently used by engineers, is the foundation of my project. Since the “cloister vault” geometry is proven to be effective in supporting structures for more than thousand years on Earth, it will do well in harsh, Martian conditons. The free-standing vault is formed around the inflatable scaffoling by small, 3D-printing robots, which use local regolith as a main construction material. The light but thick honeycomb shell provides protection against radiation and micro-metheorites. The whole complex can grow overtime – just like the International Space Station.

Connect with this team via Email.

2) The Neo Native / MOA Architecture

Since the dawn of mankind, the human spirit has expressed itself in bold dimensions, often in the personification of physical adaptability, intellectual growth, and creative expression. As a species, humans have articulated the language of spirit in the benevolent pursuit of science and exploration all the while fully contemplating the fact that the unknown is inherently divine.

Connect with this team via Facebook, Email & at www.moaarch.com.

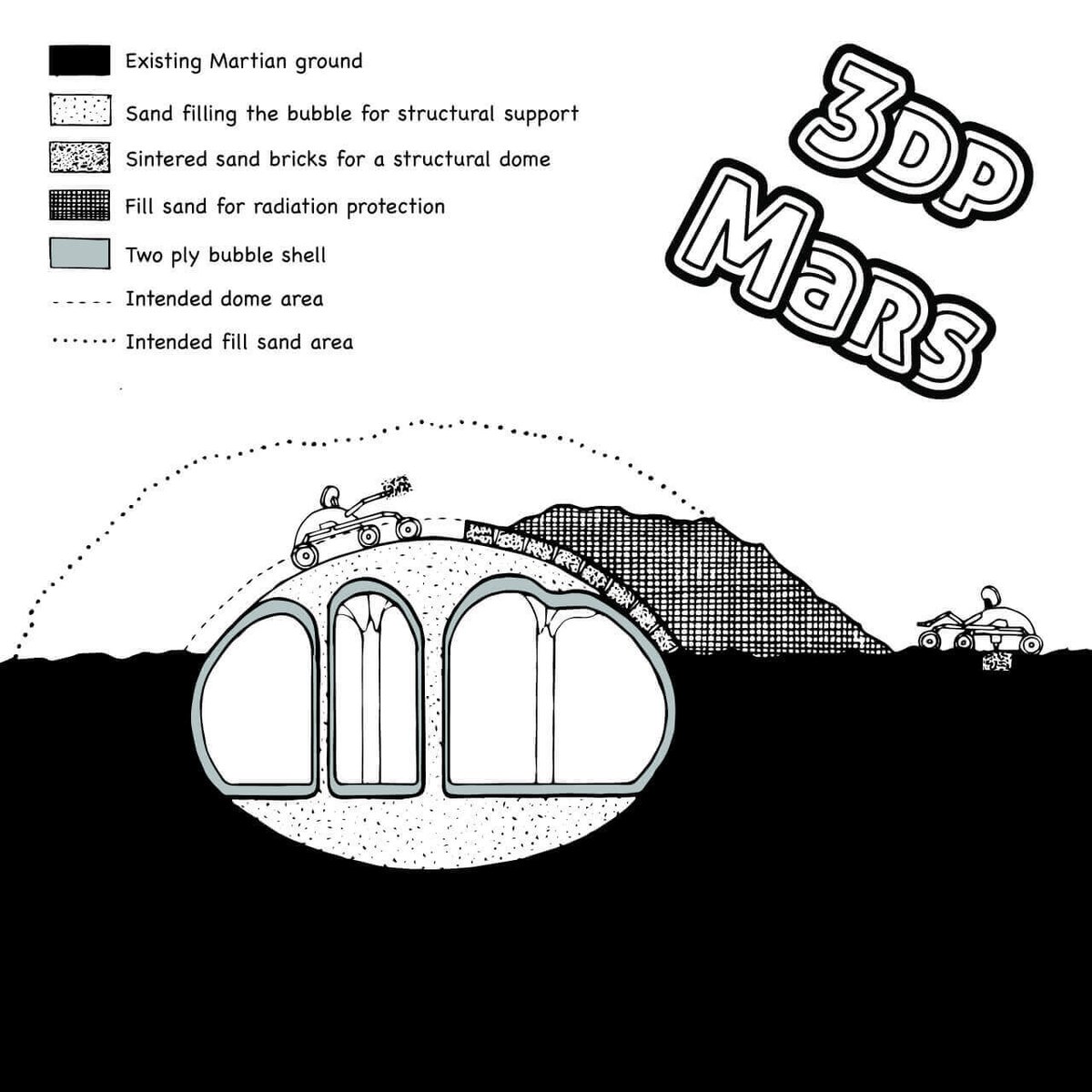

3) Bubble Base / Tridom

Bubble Base is a Smart Inflatable Structure (SIS) that introduces a smart combination between state of the art technology available on Earth, and in-situ production on Mars. By packing high performance materials in a light structure for cross planetary transportation, and filling it with Martian sand, we create a structure that is both structurally strong and technologically advanced.

Connect with this team via Facebook, Twitter, LinkedIn (LinkedIn 2).

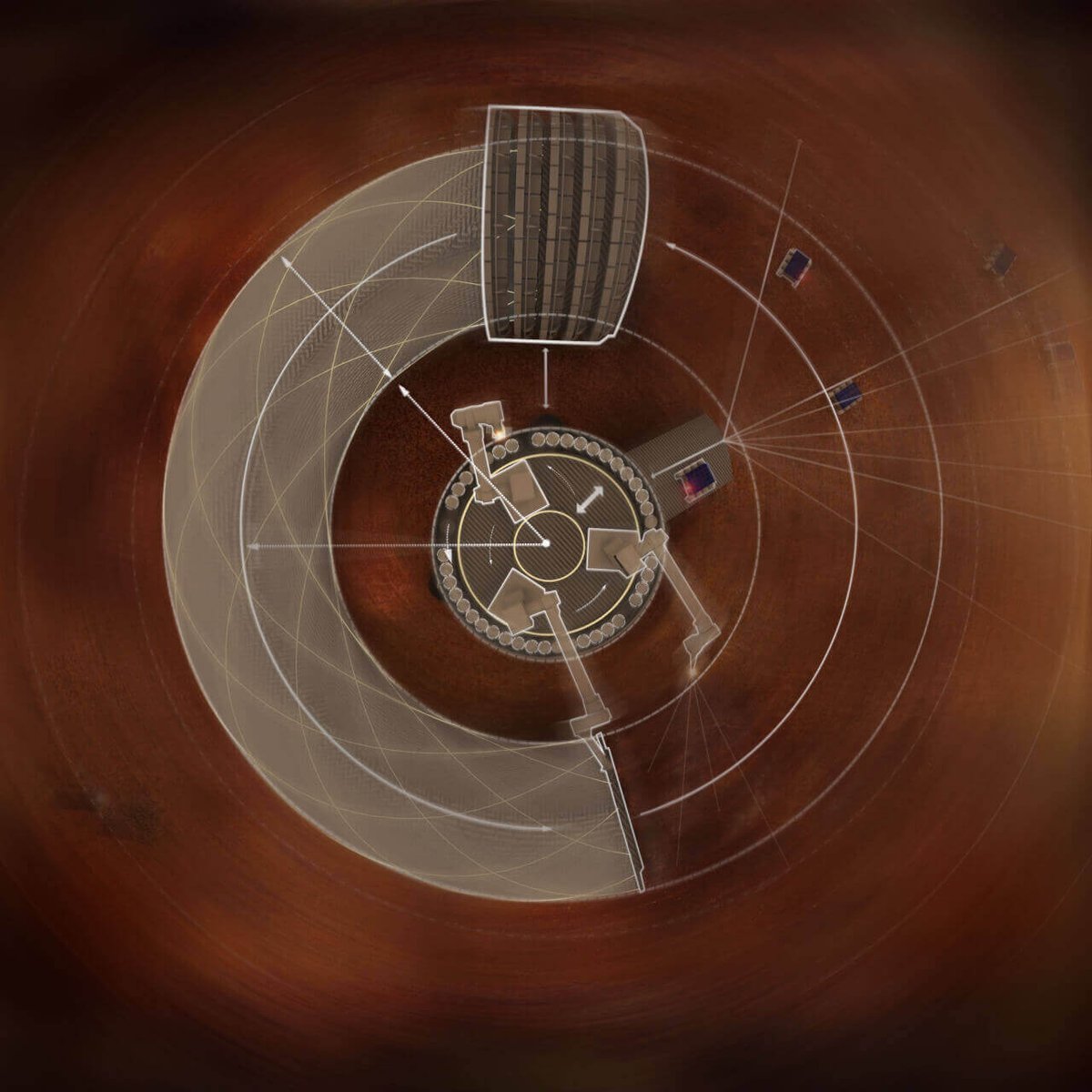

4) Ouroboros / Digital Structures

Ouroboros is an additive manufacturing and spatial concept for producing architectural-scale composite structures that are high-strength, light-weight, and air-tight—all from compounds present on Mars. A shared symbol of ancient cultures, the ouroboros is the idealized embodiment of metabolism; an infinite process of re-creation, of something beginning anew as soon as it ends. Today, the aspiration of the ouroboros persists as we seek to initiate a new and sustainable human culture of technology and design on Mars.

Connect with this team via Instagram, Tumblr, Email & at digitalstructures.mit.edu.

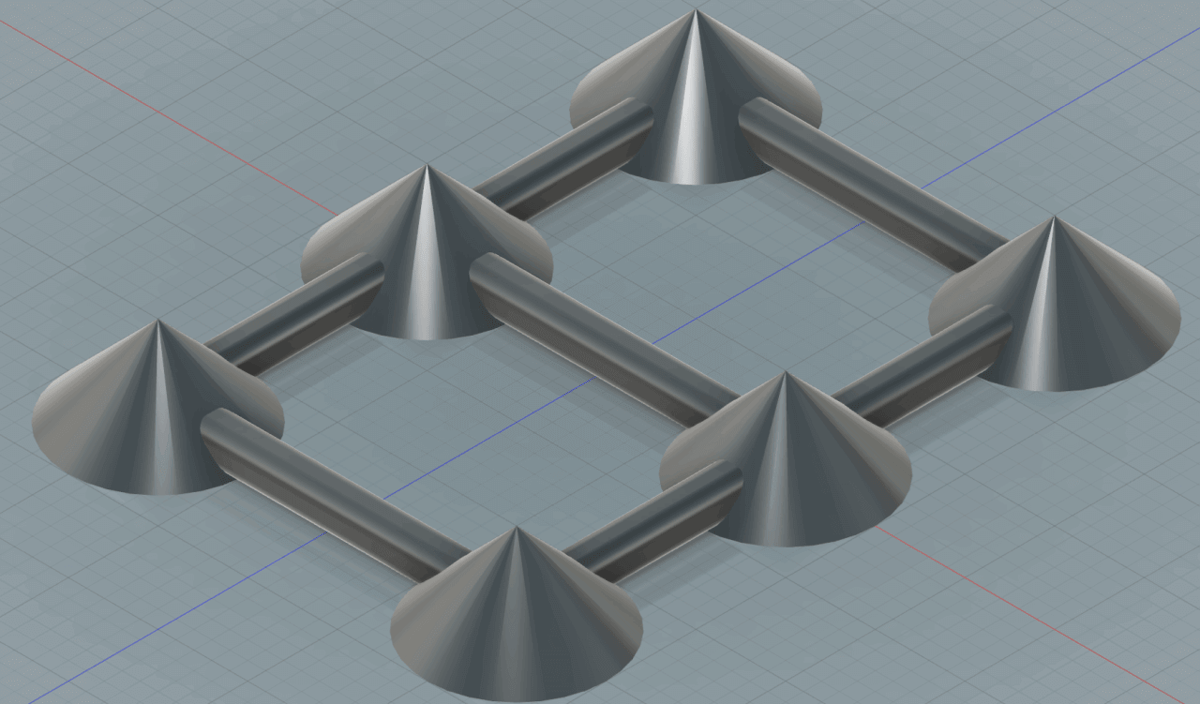

5) The Cones of Mars / 3D Fabrication Technology

A Mars base supports 4 people with integrated habitable structure creates private and social spaces. A functional and physical separation of the crew quarter, health care, dining, exercise areas, and creates a home-like design with privacy for the crew while they work for a year on Mars. The habitat will be cone-shaped to minimize snow accumulation on the roof/wall. The cone will have an outer layer and an inner layer with lattice to minimize material consumption and maximize strength.

Connect with this team via Email & at www.3dfabtech.com.

6) Hybrid Composites

Our team is a multidisciplinary group of experts who are conducting research in architecture, digital fabrication, computation, material science, additive manufacturing, robotics, mechanical engineering and aerospace engineering.

Connect with this team via Twitter, Instagram, Email & at www.ozeloffice.com.

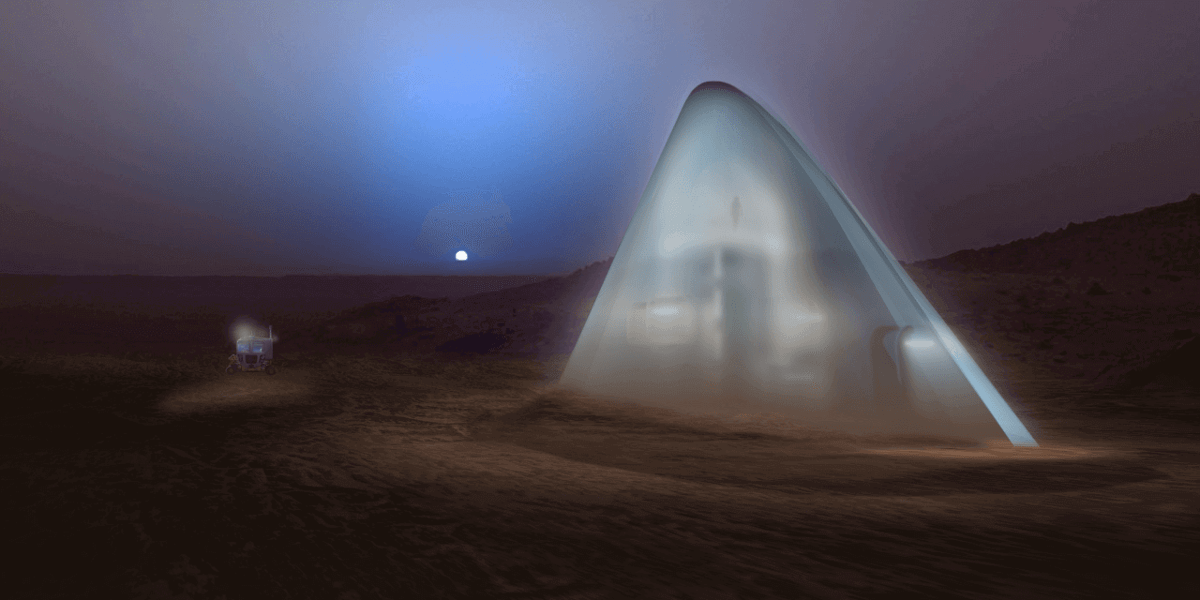

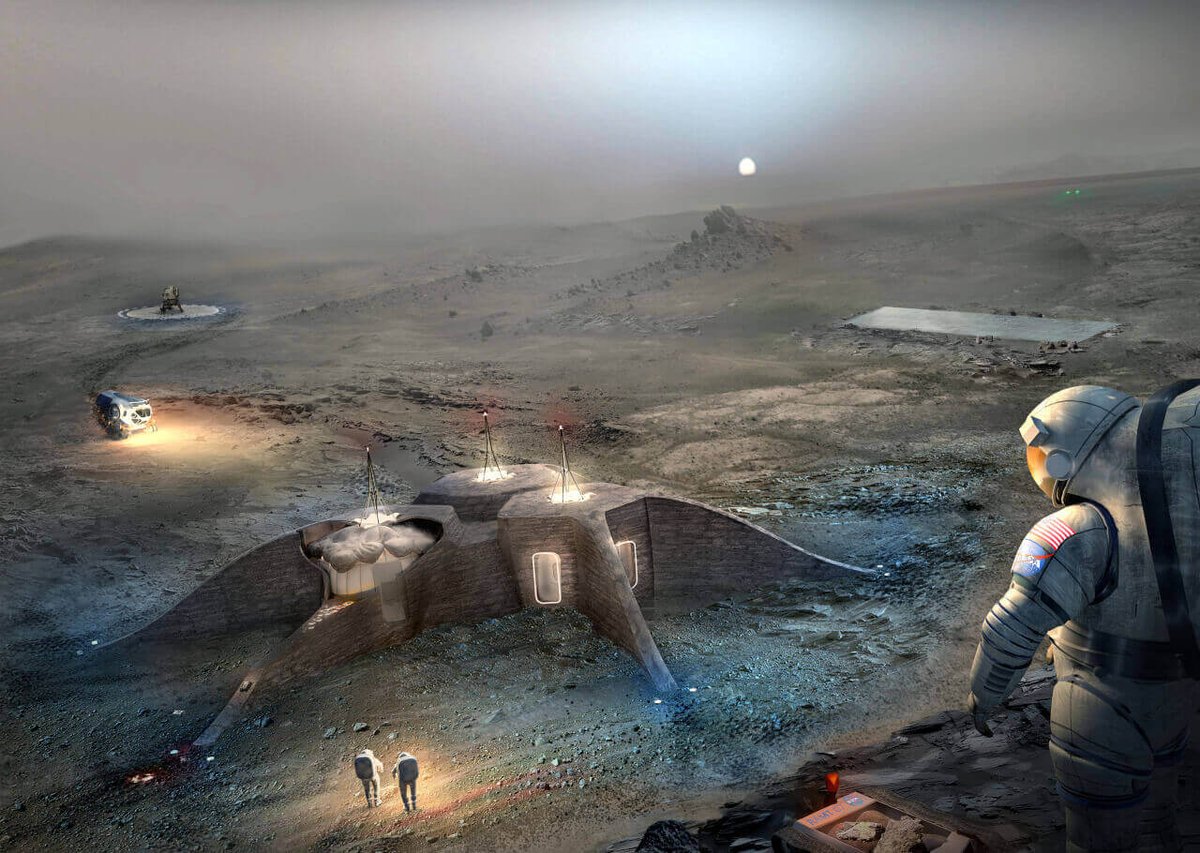

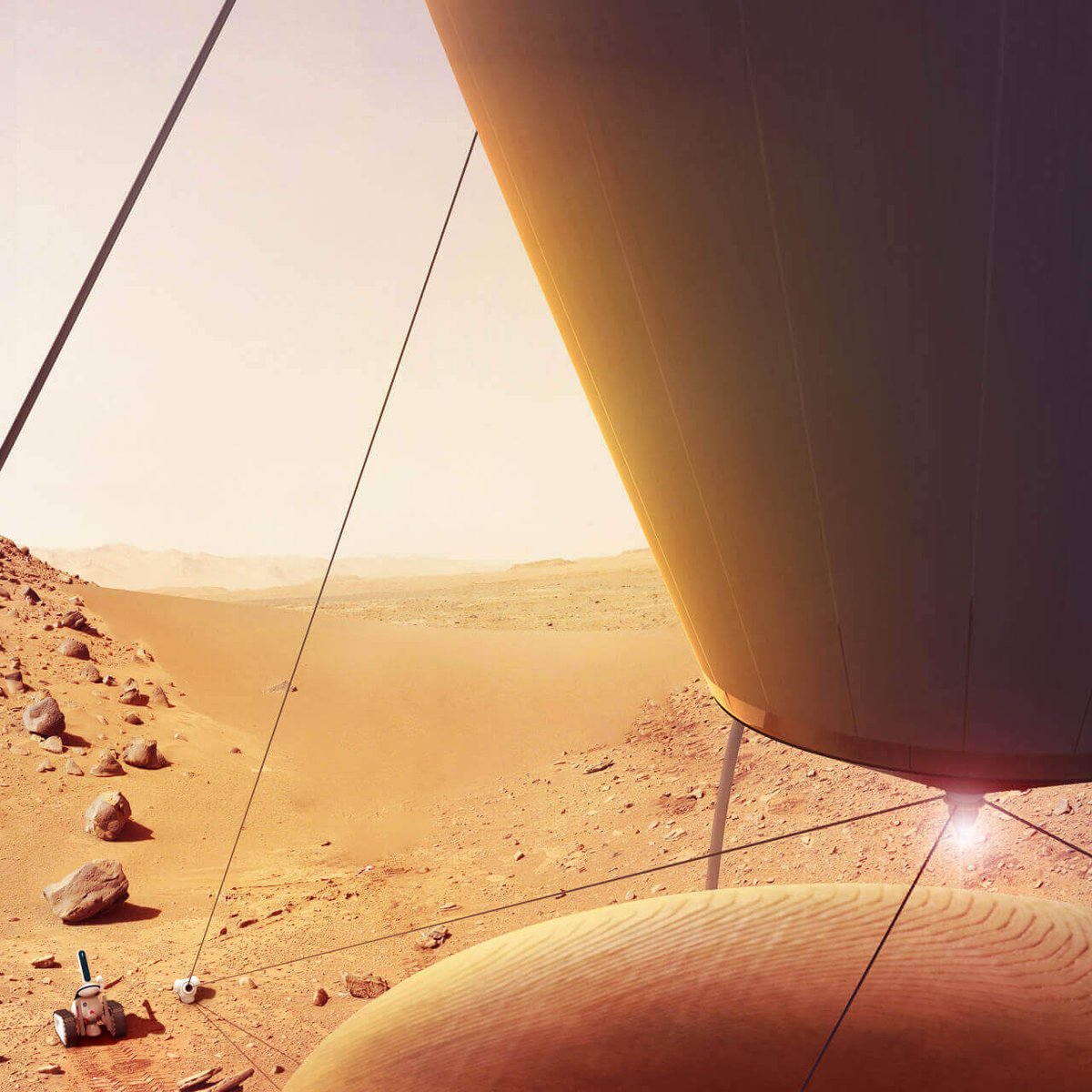

7) ICE HOUSE / SEArch/Clouds Architecture Office

ICE HOUSE is born from the imperative to bring light and a connection to the outdoors into the vocabulary of Martian architecture – to create protected space in which the mind and body will not just survive, but thrive. With water as the core resource for future outposts on extraterrestrial bodies, NASA has taken a “follow the water” approach to exploration; ICE HOUSE extends that concept to construction. The innovative structure draws on the abundance of water and persistently low temperatures in Mars’ northern latitudes to create a multi-layered pressurized radiation shell of ice that encloses a lander habitat and gardens within. A unique 3D printing technique harnesses the physics of water and its phase transition to construct ICE HOUSE.

Connect with this team via Twitter, Email & at www.cloudsao.com, www.marsicehouse.com & www.spaceexplorationarchitecture.com.

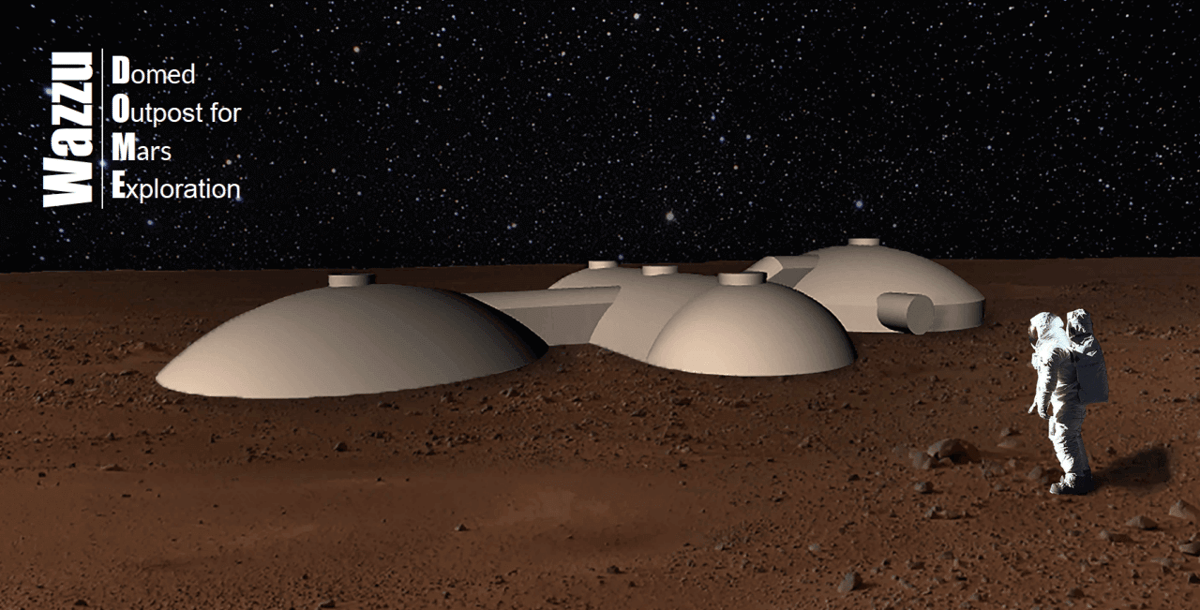

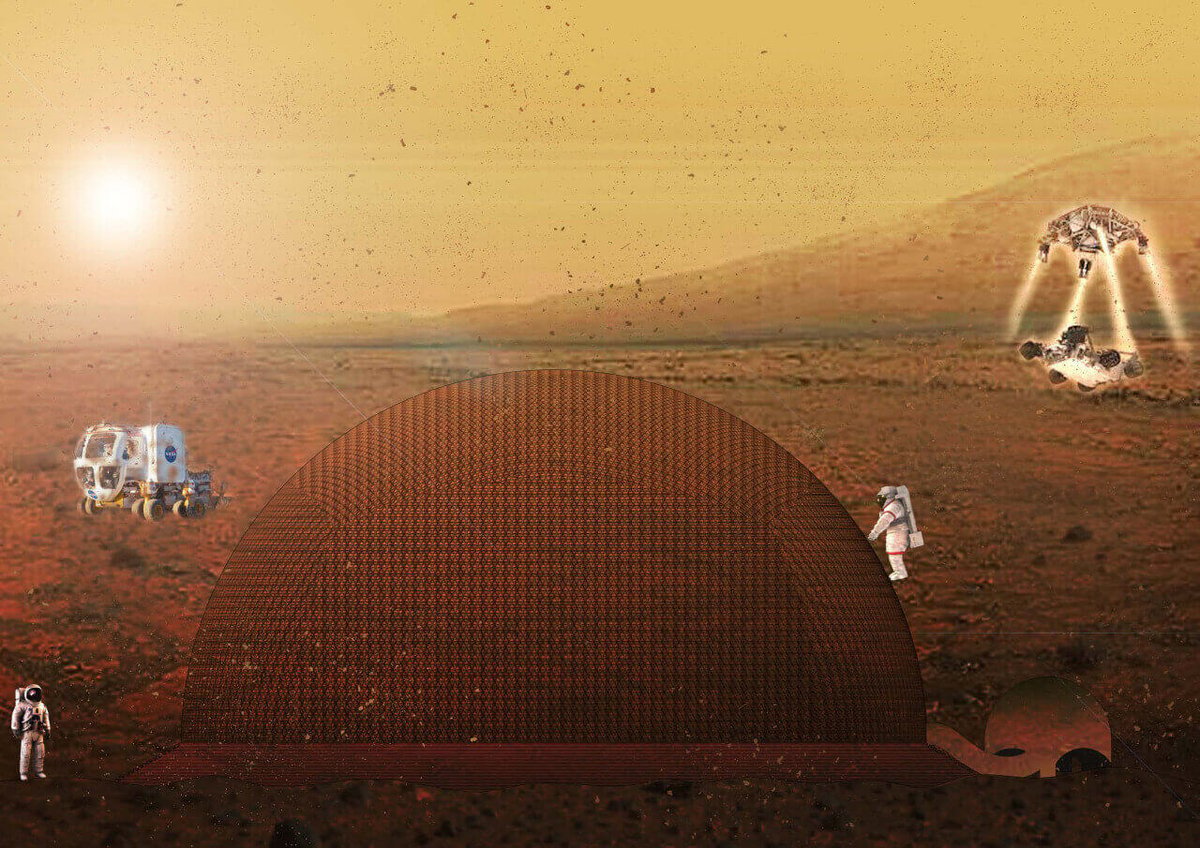

8) Wazzu DOME (Domed Outpost for Mars Exploration) / WSU 3D Printing Research Team

Our team has developed an architectural design named Wazzu DOME, that will take advantage of a novel 3D printing process, requiring only in situ resources on Mars i.e., Martian regolith, to build a dome structure for a settlement. The process deposits regolith layer-by-layer while simultaneously converting it into stable walls through the use of microwave sintering. The structure is built in the area where the regolith is harvested, making the structure partially underground.

Connect with this team via Twitter (Twitter 2, Twitter 3) & Email.

9) Marsapia / Mars Terrain Intelligence Collaborative

The most ubiquitous and accessible material on Mars is the high (6-14%) iron content silica sand which covers the vast majority of the planet’s surface. Once the iron and silica have been separated from the soil matrix, using thermal and magnetic processes, these materials will be moved to hoppers and become the media for induction extrusion /plasma arc sintering heads, positioned by multi-axis CNC hydraulic/servo-driven arms. These robot controlled print-heads will produce first permanent structures on Mars.

Connect with this team via Email, Blogspot & Issuu (Issuu 2).

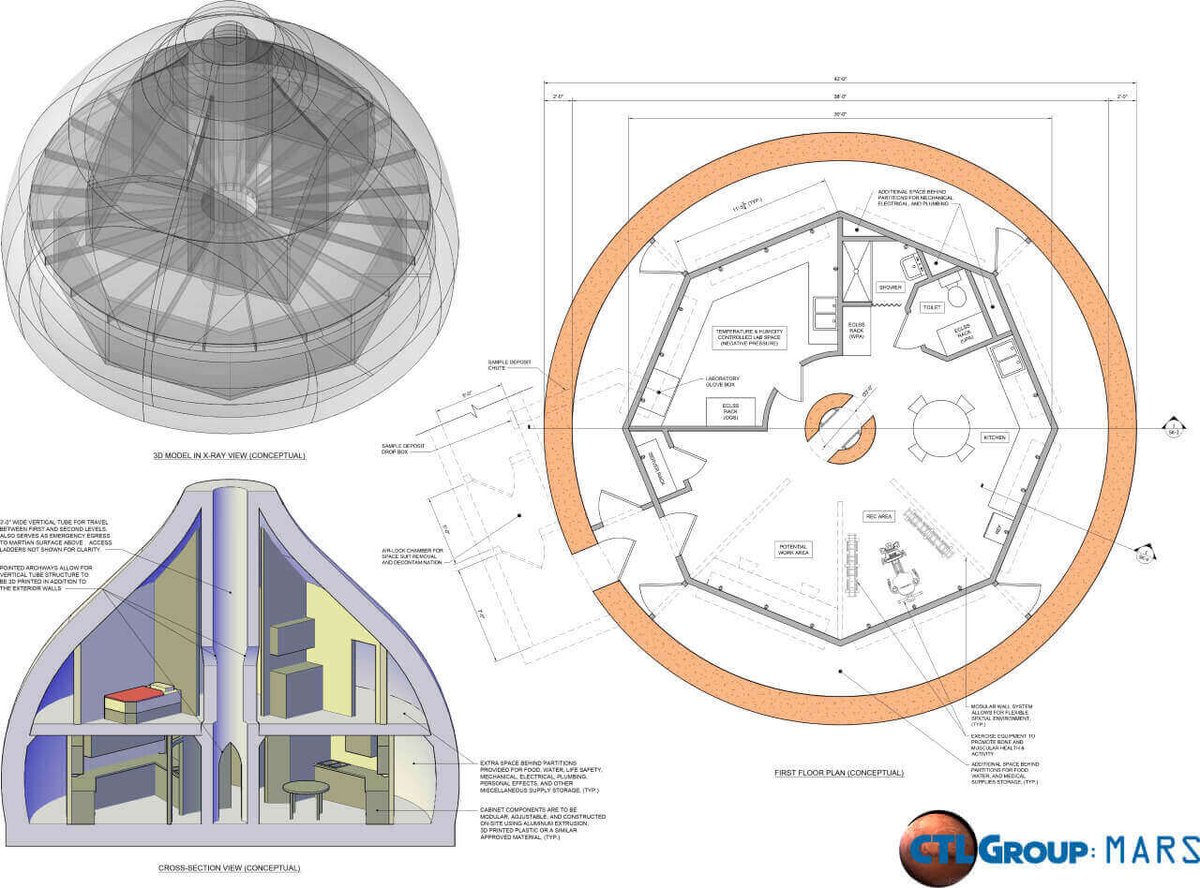

10) Seed Habitat / CTLGroup Mars

CTLGroup:Mars’ submission to the 3D-printed habitat challenge combines advances in our ability to “print” structurally sound materials and solutions to engineering challenges devised in ancient Rome. The structure we propose is informed by ancient concrete designs that did not include reinforcing steel (which is difficult to manufacture on Mars or to transport from Earth) and by investigations into the use of concrete for lunar structures that took place in the 1980’s. Additive manufacturing technologies allow for structural customization to suit any location of interest on Mars.

Connect with this team via Twitter, Instagram, LinkedIn, Email & at www.ctlgroup.com.

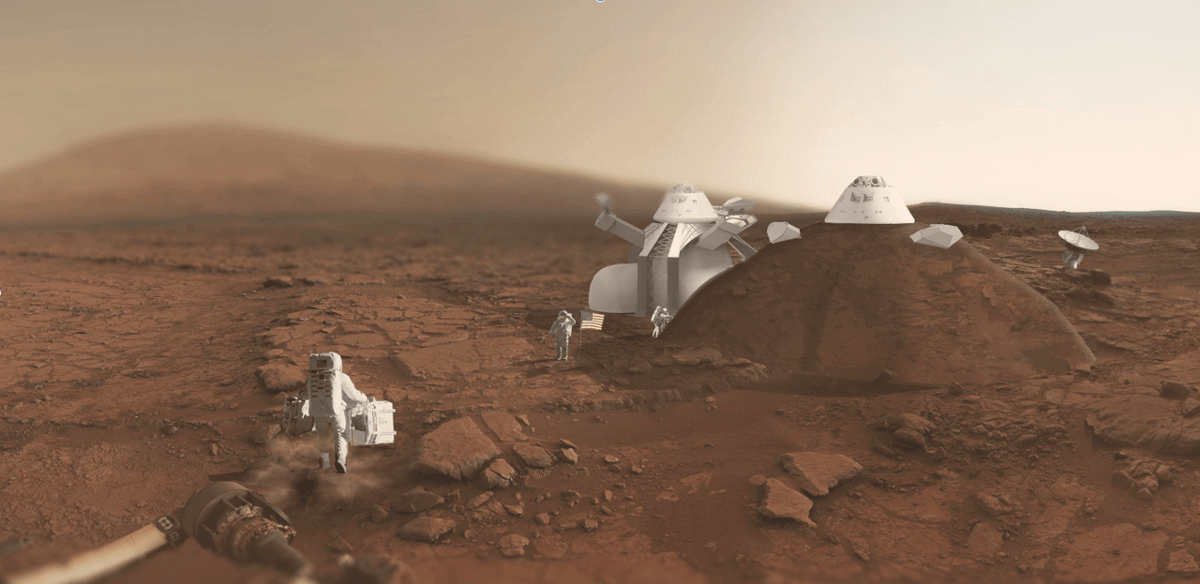

11) Regolith Geodesic Dome Habitat / NBVS

The Mars habitat would provide a safe and viable living environment for the brave astronauts whose destiny it would be to undertake the mission to Mars. The mission would consist of three phases, the first two of which would be unmanned. First, a surveying expedition, then the construction phase, and lastly the manned supply launch.

Connect with this team via Email.

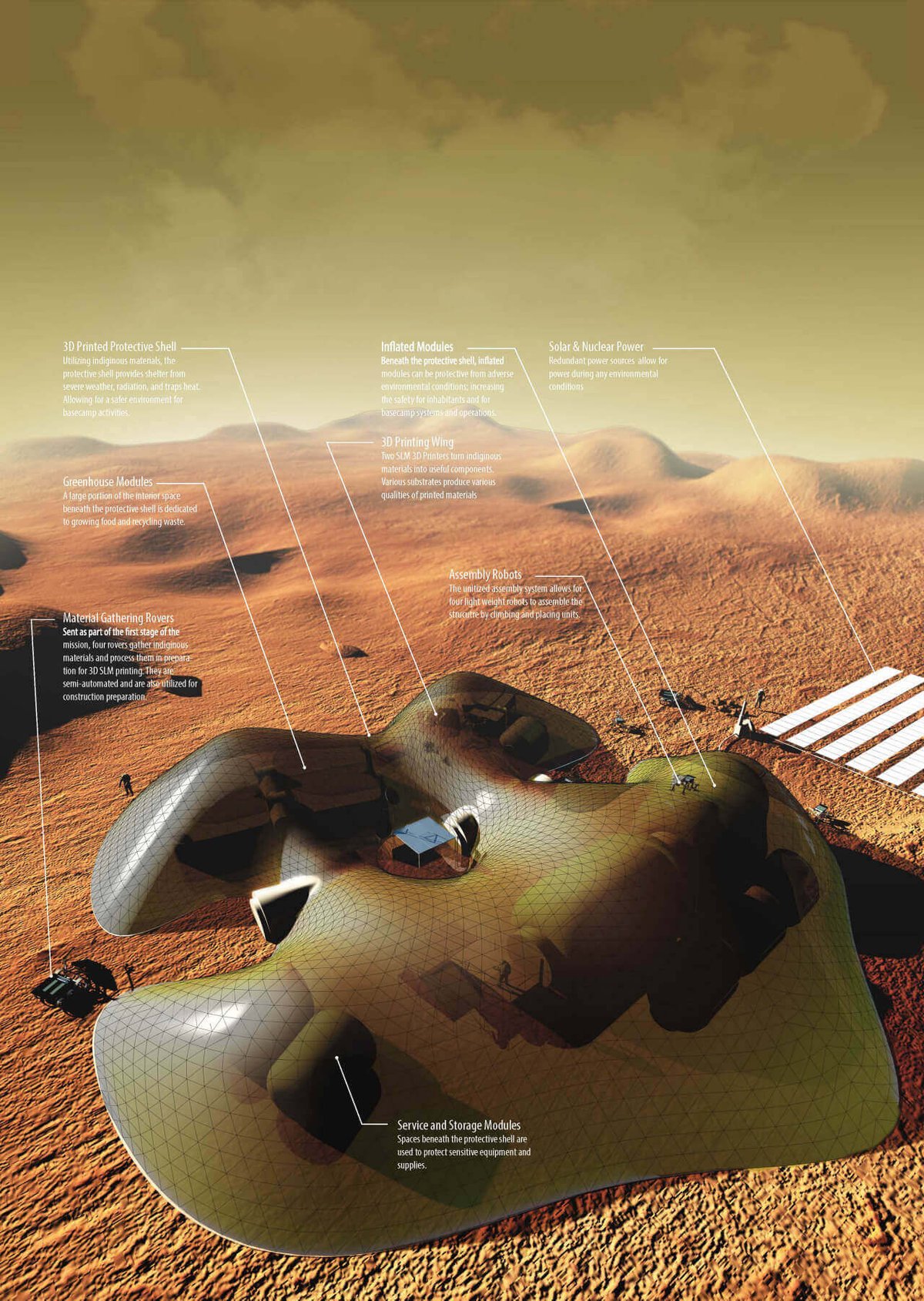

12) Mars Artificial Atmospheric Envelope (M.A.A.E.) / MP1-S7

The Mars Artificial Atmospheric Envelope (M.A.A.E.) is designed to be a resilient shell to Mars’s extreme conditions while advancing 3D printing technologies with in-situ resources. M.A.A.E. utilizes a multilayer structural system comprised of both 3D printed in-situ material and an inatable shell made of recyclable ETFE. The 3D printing methods and structure are based on biomimicry. In nature, bees use hexagons to construct their hive as the symmetry reduces the complexity of the structure by its strength to eciency ratio and its smallest total perimeter. The geometry helps maintain consistent sizing, allowing multiple bees to work on various construction areas concurrently. This natural occurrence sets the precedence for using multiple printers simultaneously during construction.

Connect with this team via Twitter & Email.

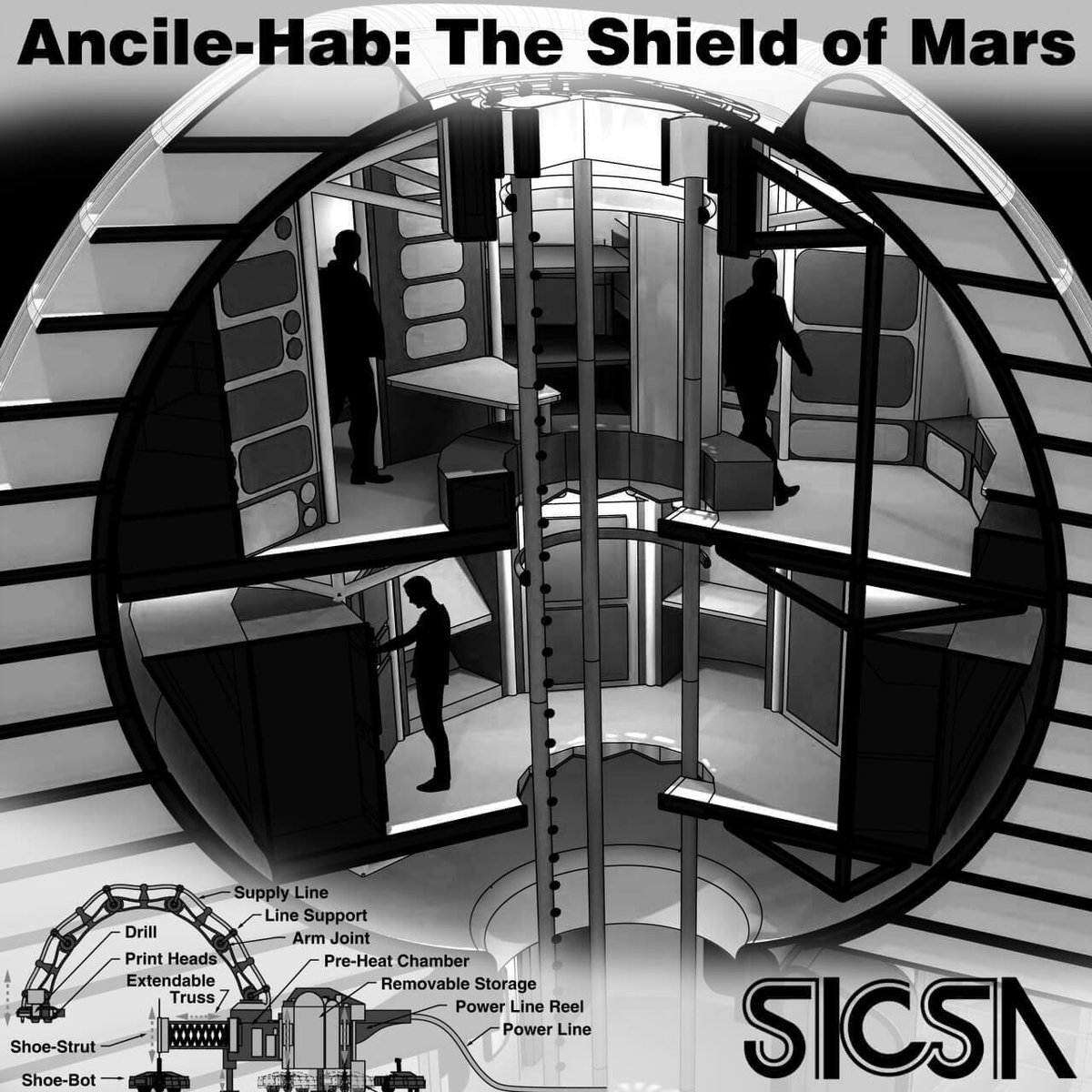

13) Ancile-Hab: The Shield of Mars / SICSA

The habitat design uses in-situ resources to print the protective external structure of the Mars outpost, an approach which will greatly reduce launch up-mass and cost while decreasing radiation and micrometeorite risks. The name “Ancile-Hab” originates from the Ancile shield given to humans by the Roman God Mars, this shield will protect humans from hazards of the Martian environment. Beginning by landing a power plant, mobile 3D-Printer/Processor (3DP), and Multi-Purpose Shoe Bots (MPSBs). The MPSBs position the 3DP and the power plant, connect them together, and start collecting loose regolith to deposit into the 3DP’s processors. The MPSBs repeat this cycle to insure continuous material input for uninterrupted printing. The 3DP first prints the foundation and then begins printing the protective mound and the pressure vessel within.

Connect with this team via LinkedIn (LinkedIn 2), Facebook, Email & at www.sicsa.egr.uh.edu.

14) Mars Hab N1

The Mars Hab N1 team’s habitat design architecture has achieved five major goals: (1) On site (@ Mars) 3D printability of all the habitat structural components (including Alon glass for habitat windows), (2) Simple & robust habitat fabrication / assembly on Mars by the human crew, using a Martian 3D printer capable of using metallic powder obtained through ISRU processes that the team has evaluated for the Martian 3D printer, (3) Habitat sustainability to support a living & laboratory station for at least four crew members using Nuclear Radioisotope Power system which will provide power, heating and lighting, (4) An intelligent hydroponics platform to provide sustainable food and oxygen supply for the crew members and (5) In-depth trade study analysis with appropriate figure of merits to challenge existing NASA habitat architectures for Mars colony concepts in order to prove that the team’s design is better in safety, feasibility, cost and practicality.

Connect with this team via Facebook (Facebook 2), Email & at www.hbartech.com & www.howeindustries.net.

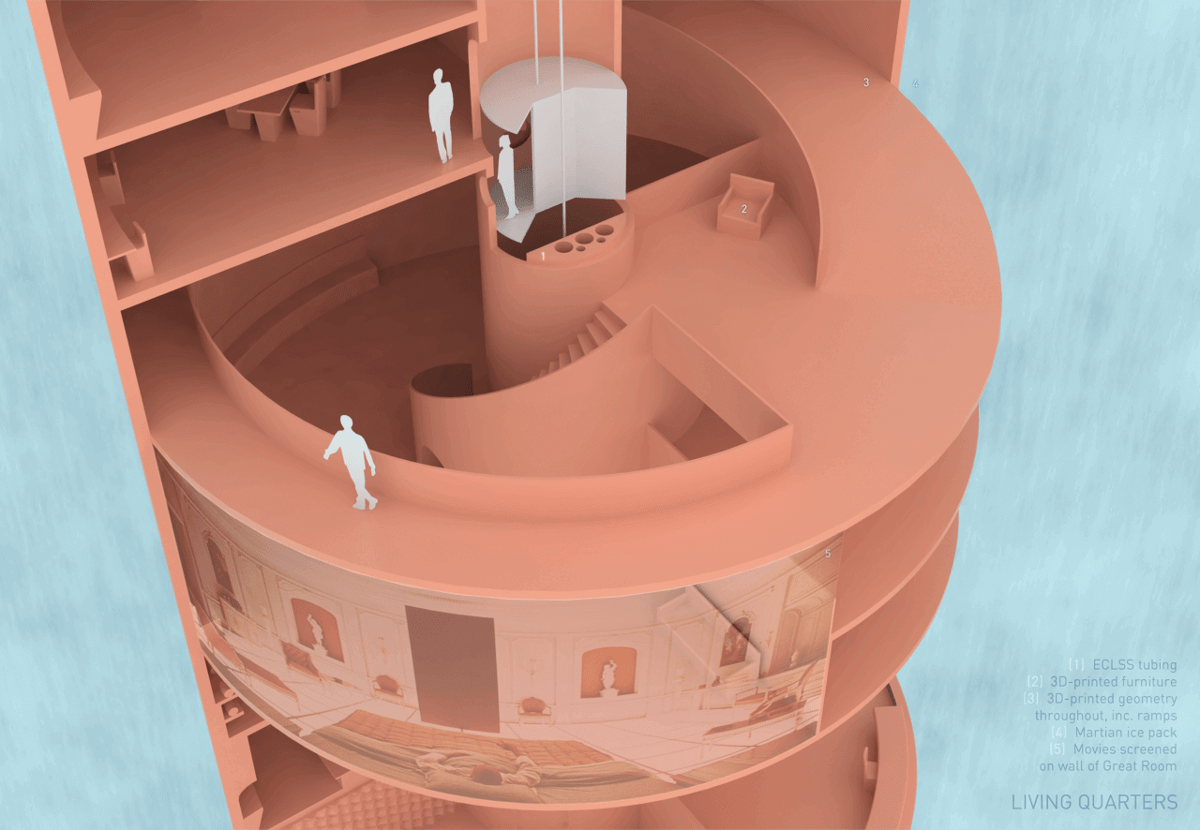

15) Team Staye

We believe that boring into the ice of the Equatorial Frozen Sea is the best strategy for initiating a Mars settlement. Easy access to water, protection from cosmic rays, and warm daytime temperatures make this location ideal. Our proposal is based around a silo-shaped habitation, 3D-printed in cement, beginning at the bottom of the bore hole. The silo comprises multiple levels, each having a different programmatic focus. Cement 3D printing enables the creation of walls, cabinetry, furniture, and more, with greater speed, task-specificity, and durability than would otherwise be possible.

Connect with this team via Email.

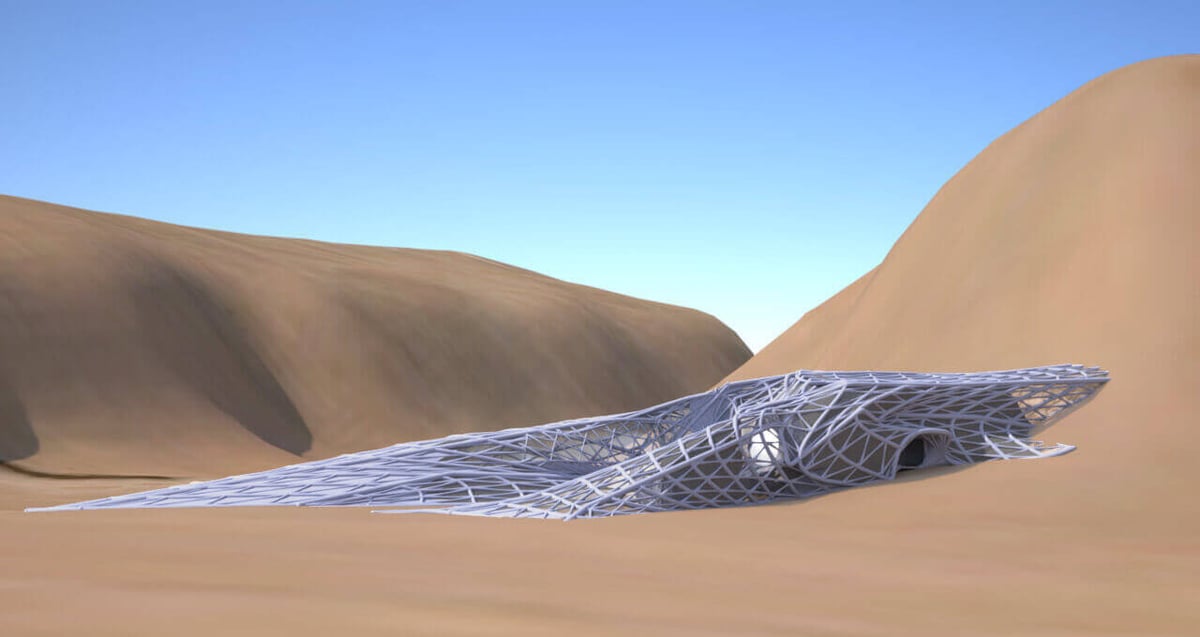

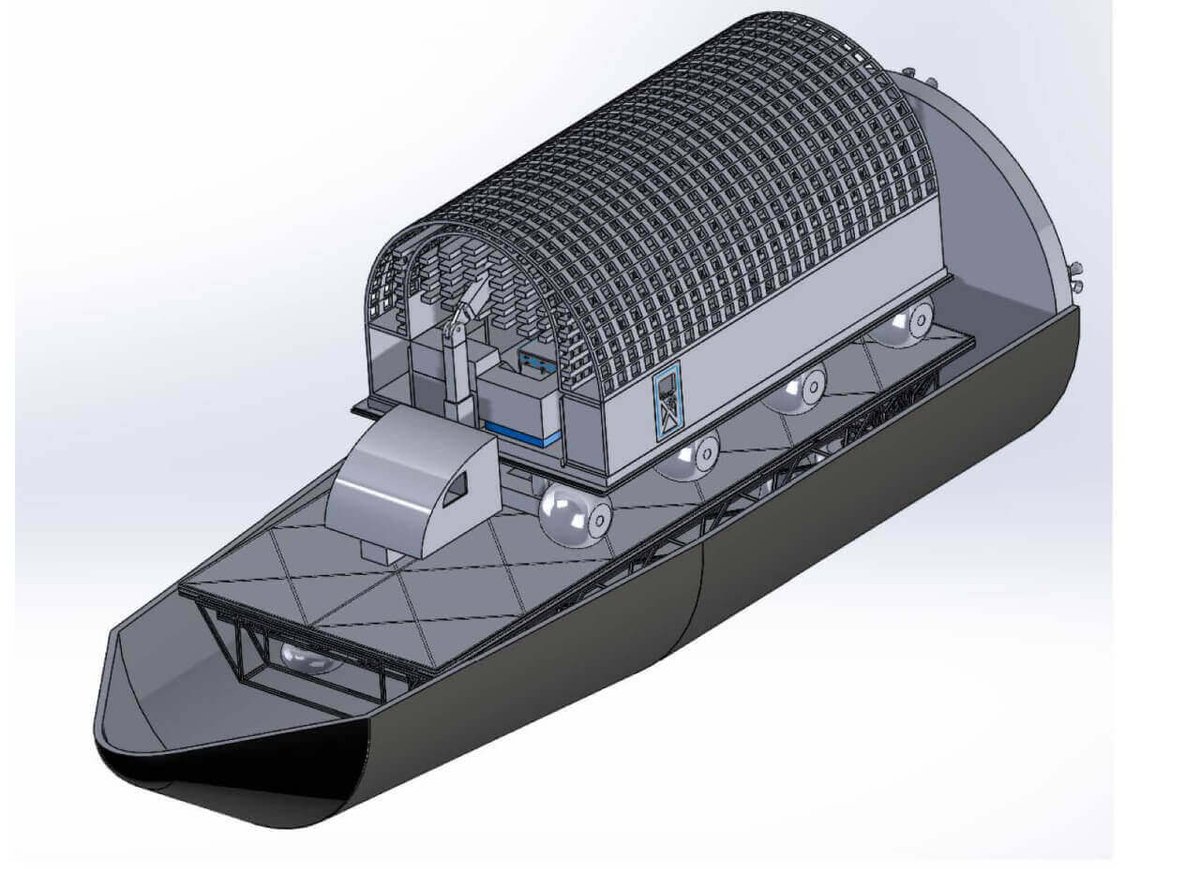

16) Mollusca L5 / LeeLabs

Our concept proposes a design and methodology for a Mars shell/membrane system to create a protected space for inflated habitation modules and outdoor areas while utilizing 100% indigenous materials as the 3D printing substrate. The vaulted structure is adaptable to a range of geographical conditions and habitat sizes through an open-platform 3D printed modular construction and fabrication system. The approach is modularized into separate upgradable stages: Material Prep, Fabrication, and Assembly, converting regolith into high strength glass panels. The interior layer is composed of inflatable units (provisioned from Earth) and configured for redundancy and utility. The exterior layer of locally sourced and fabricated modular glass units allow for a generative designed shell structure, providing the inhabitant with protection from severe weather, high radiation, small impacts, and extreme temperatures. The “front yard” typology allows the inhabitants to further engage with the Martian environment under the protective shell. This approach facilitates future growth of the habitation camp, as the exterior shell can be extended, adjusted, and repaired thanks to its unitized nature.

Connect with this team via Facebook, Twitter & Email.

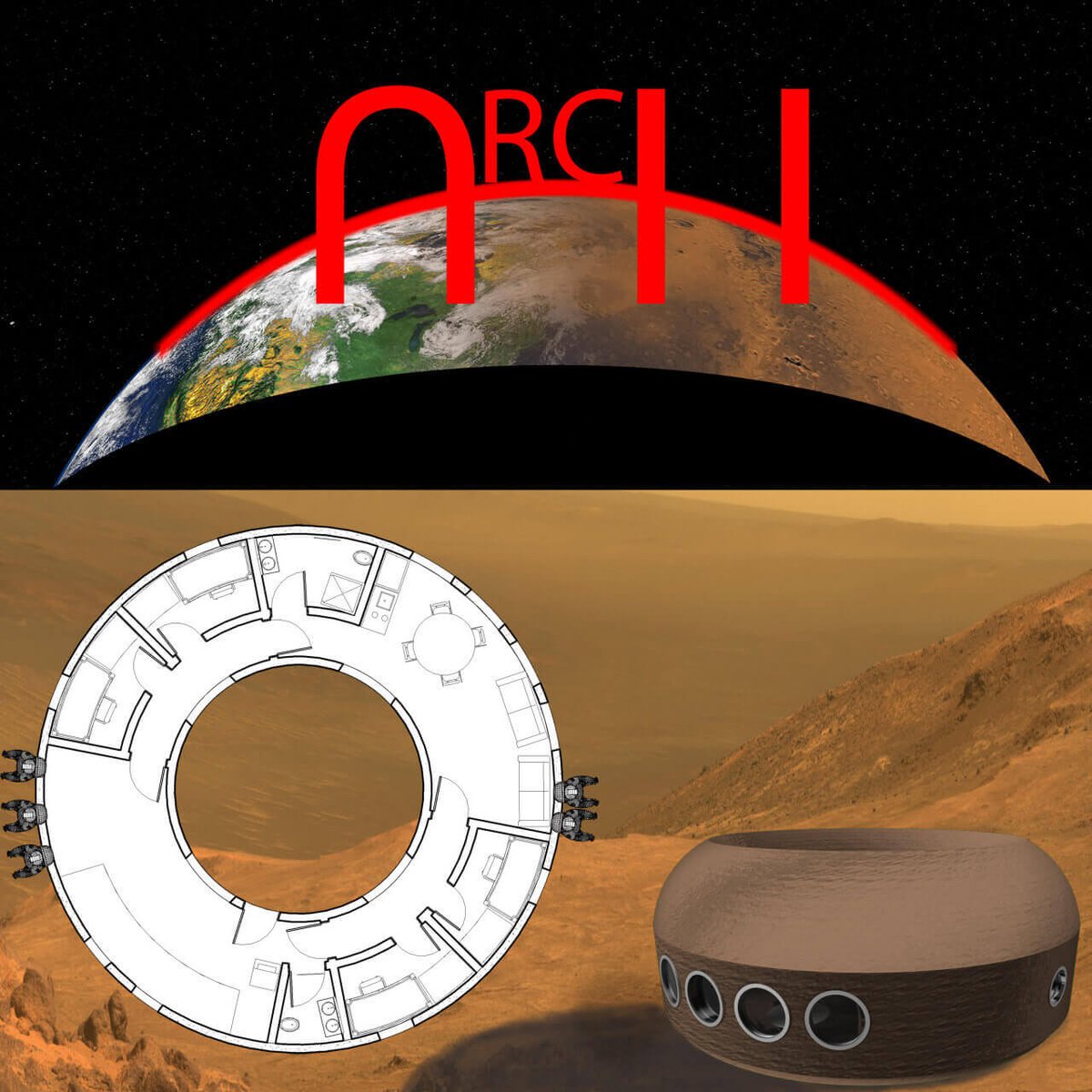

17) Donut House Mk. I / A.R.C.H.

Team A.R.C.H’s submission uses the design and construction methodology of basalt fiber clay matrix structures for in-situ habitat construction on Mars and other celestial bodies.

Connect with this team via Twitter, Facebook & Email.

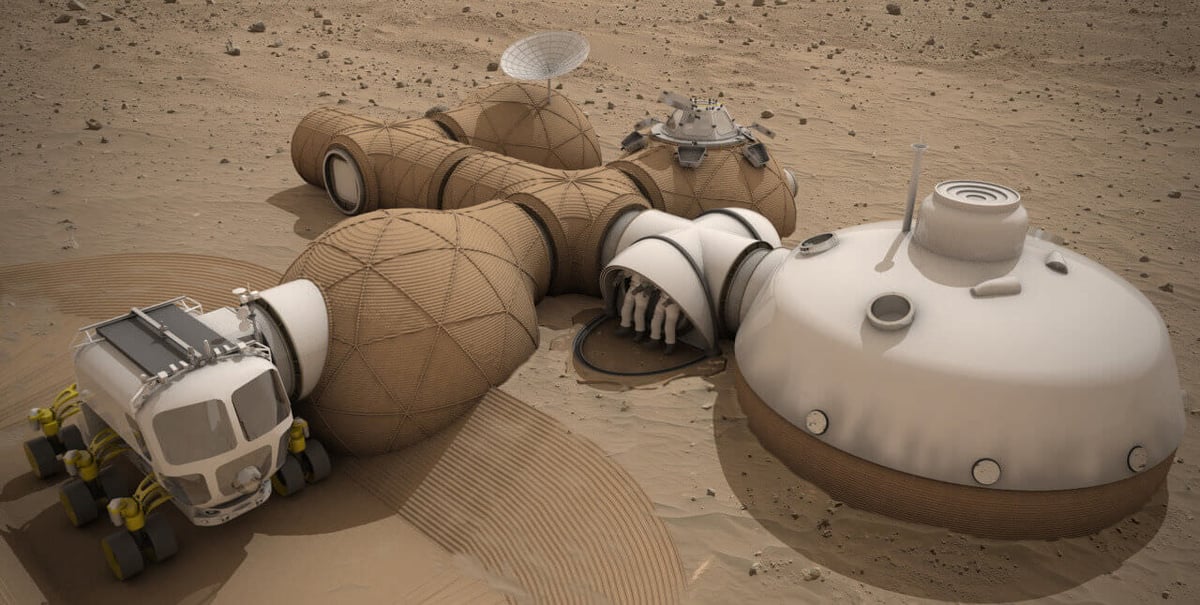

18) GAMMA

A semi-autonomous multi-robot regolith additive manufacturing (RAM) system is used to create a protective in situ shield around a modular inflatable hab. The proposal primarily explores system and design redundancy through distributed functionality: from the initial descent and navigation of the three inflatable dodecohedral modules to find a suitable location; with the flexible and interchangeable internal habitat design; through to the multi-robot microwave regolith melting. Even more fundamentally, allowing for unknown outcomes acknowledges the uncertainty in the frontier environment and the mission, shown in the freedom of the deployment, the module arrangement, and construction process.

Connect with this team via Twitter (Twitter 2) & Email.

19) INMODE

This concept is the outcome of a modular approach to habitat design for simplified self-assembly. Its main torus is the central element of the habitat carrying all construction relevant tools and material as well as the core systems. Attached to it are four sleeping modules, a lab and a recreational area. The larger number of individual modules simplifies the construction process, increases privacy and allows for better airflow options. The modules are built using a combination of metal extrude printing (for framing), laser sintering (using CVD or PVD), FDM, an alternative technique and circuit printing. In a first step, the basic shape of the module is inflated. The construction process then takes place inside the inflated structure using ALM robots. The main power lines are preinstalled inside the floor of the modules and connected to the printed circuits on the walls. Construction takes place one module at a time, allowing for better troubleshooting.

Connect with this team via Email.

20) N3ST / N.E.S.T.

The N3ST (Nested 3D-Printed Settlement Technology), is a safe-to-fail design based on the principles of redundancy, simplicity and incrementalism, which aims 1) to provide atmospheric stabilization, to allow robotic-building in safe conditions, minimizing error and robot failure; 2) to create a life-supporting milieu, granting the physiological conditions necessary for human life; and 3) to generate functional, comfortable infrastructure, understood as design solutions oriented to efficiently support anthropogenic use of the space. These goals are achieved by way of three functional layers: The Exo-layer provides a primary protection to the settlement, that is, to quickly stabilize atmospheric conditions for further development of tasks that require greater control. The Meso-layer is an hermetic volume wich provides an atmosphere with the necessary physiological conditions for sustaining the human life, controlled by the ECLSS. Finally, the Endo-layer creates all the necessary for the development of the activities performed by the crew members, like furniture and resources supply networks.

Connect with this team via Facebook, Twitter, Email & at www.n3st.cl.

21) Hemispheric Habitat / Martian Domes

Team Martian Domes aims to build a comfortable, expandable and sustainable community through the Hemispheric Habitat. It is an architectural concept focusing on creating home on Mars for the explorers. Drawing inspiration from the earthworm, the printing concept features simultaneous excavation of local indigenous materials on one end and printing the habitat on the other. All printed accurately and automatically before the arrival of astronauts.

Connect with this team via Facebook, Twitter & Email.

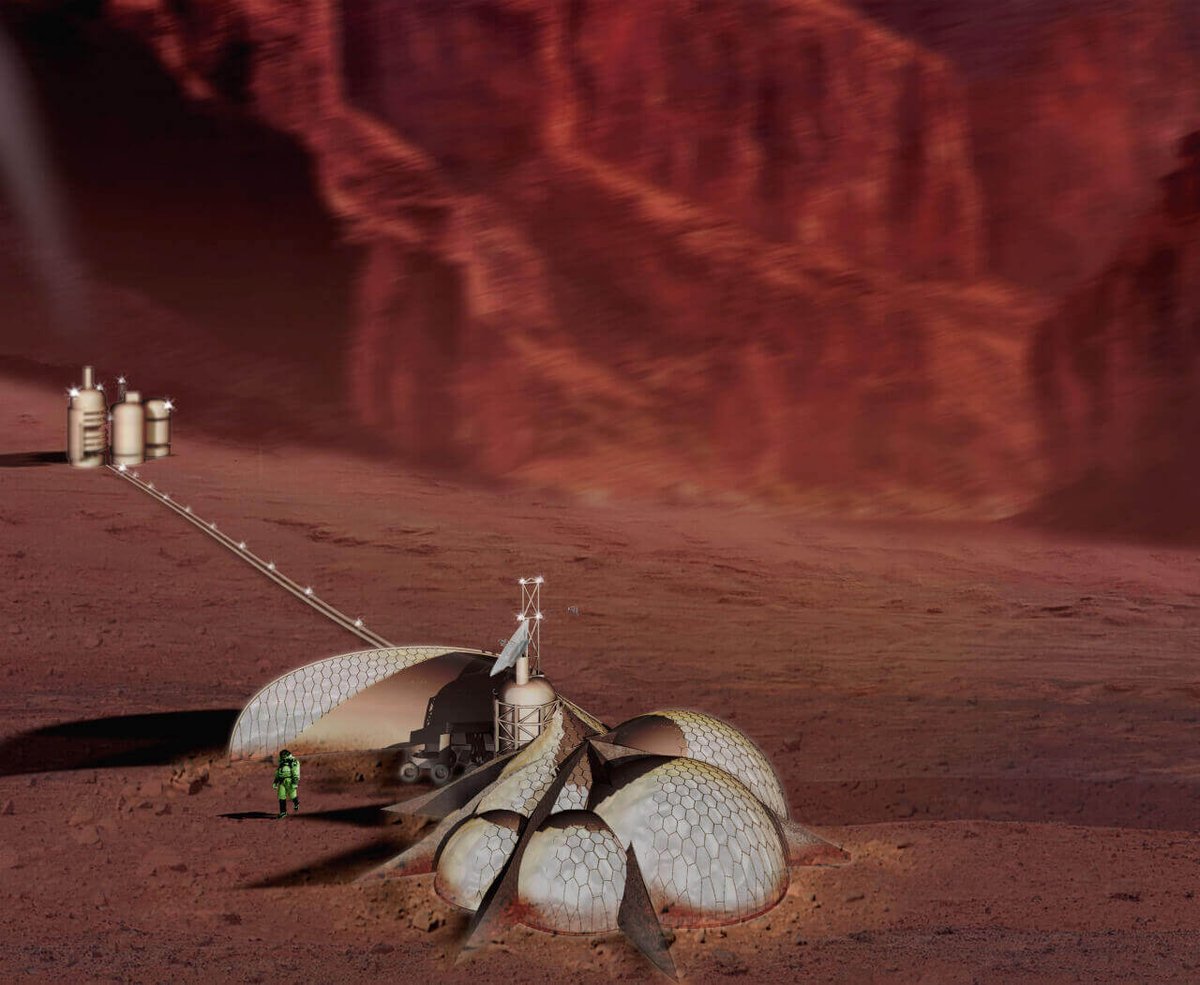

22) LavaHive

LavaHive is a modular, additive-manufactured Martian habitat design using a proposed novel ‘lava-casting’ construction technique as well as utilizing recycled spacecraft materials and structures. Our design incorporates usually discarded components as a key element of the habitat concept. The back shell of the Entry, Descent and Landing (EDL) system that will deliver the construction rovers will be used for the primary habitat roof, with an inflatable module underneath as the primary living habitat. Using the readily available Martian regolith, two rovers will use a combination of sintering and ‘lava-casting’ to build connecting corridors and sub-habitats around the main inflatable section. These sub-habitats will then be fitted, sealed internally with epoxy and furnished as a research area, workshop or greenhouse depending on the mission design.

Connect with this team via Facebook, Twitter & Email.

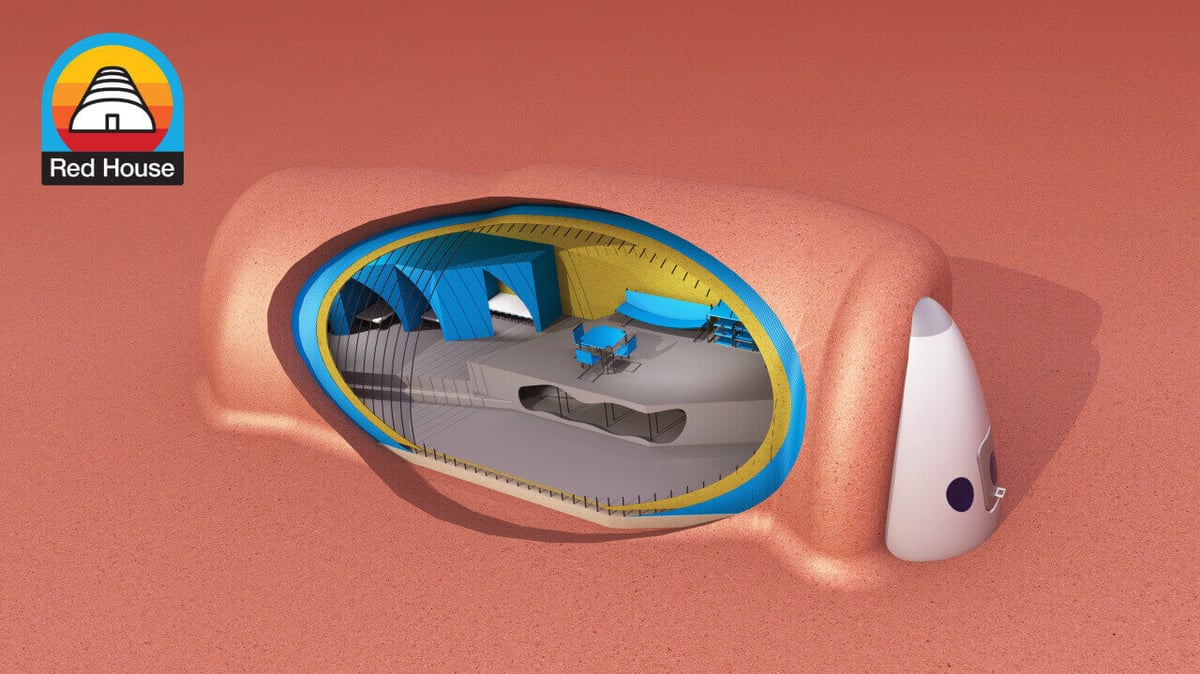

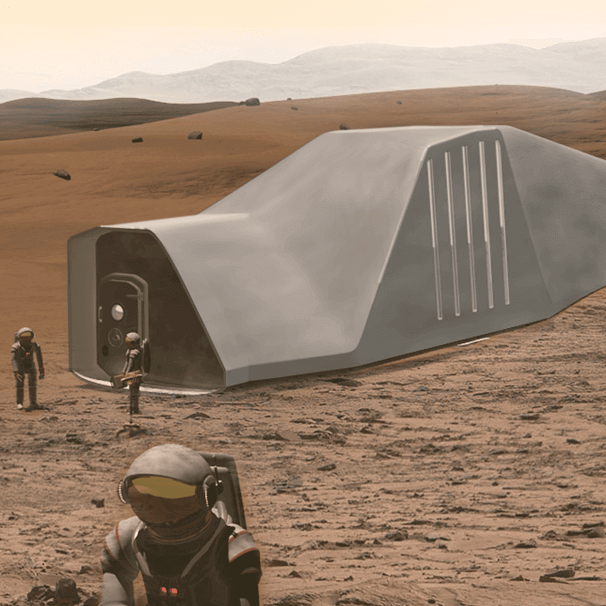

23) Outpost Olympus / Red House

The Red House team, a collaboration amongst a group of graduate and undergraduate students studying Industrial Design, Graphic Design, Architecture, and Physics, undertook an iterative design process to arrive at a novel approach to Martian habitation. We recognized that in order to reduce the enormous cost of human exploration on Mars, innovative construction techniques must be brought to bear. Since the most expensive resource on Mars is human labor, our approach makes use of autonomous manufacturing via 3D Printing. To offset the cost of the next most expensive resource, mass launched from earth, we sought ways to incorporate in situ resource utilization.

Connect with this team via Email & at www.teamredhouse.com.

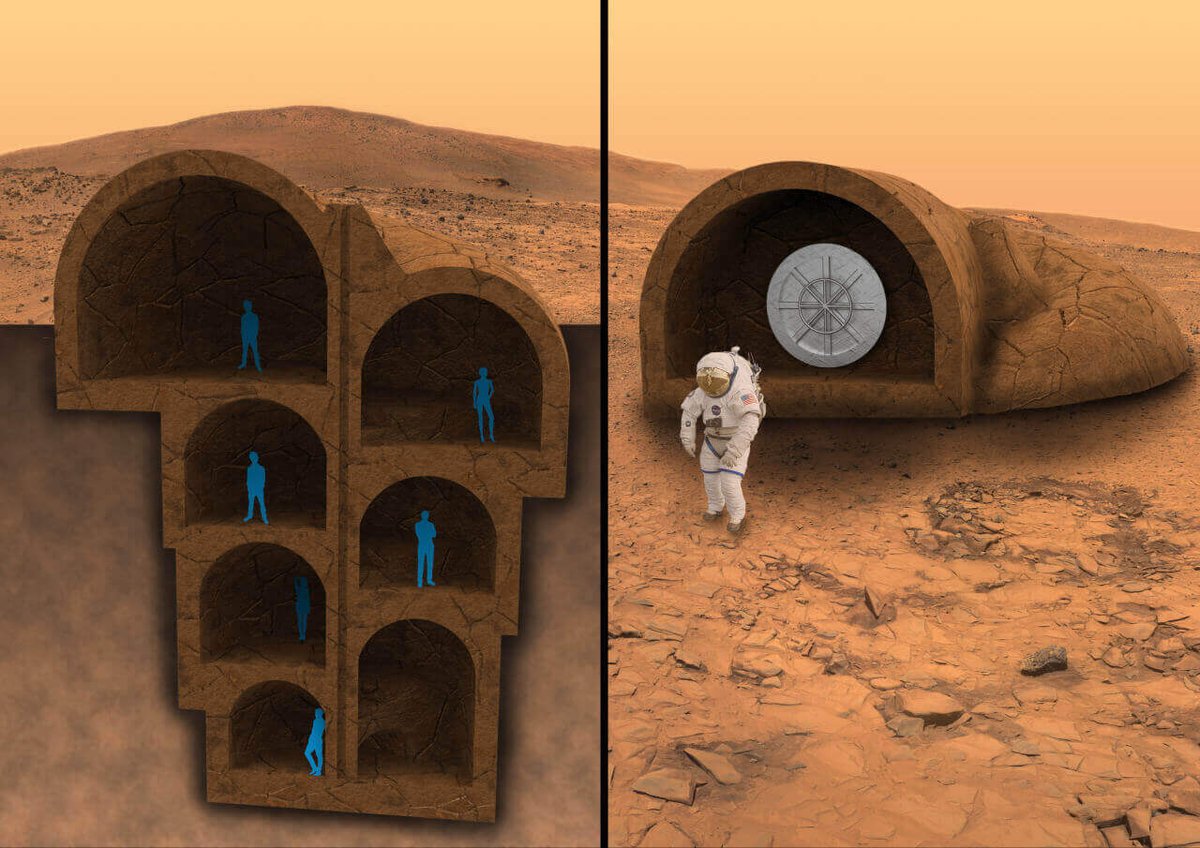

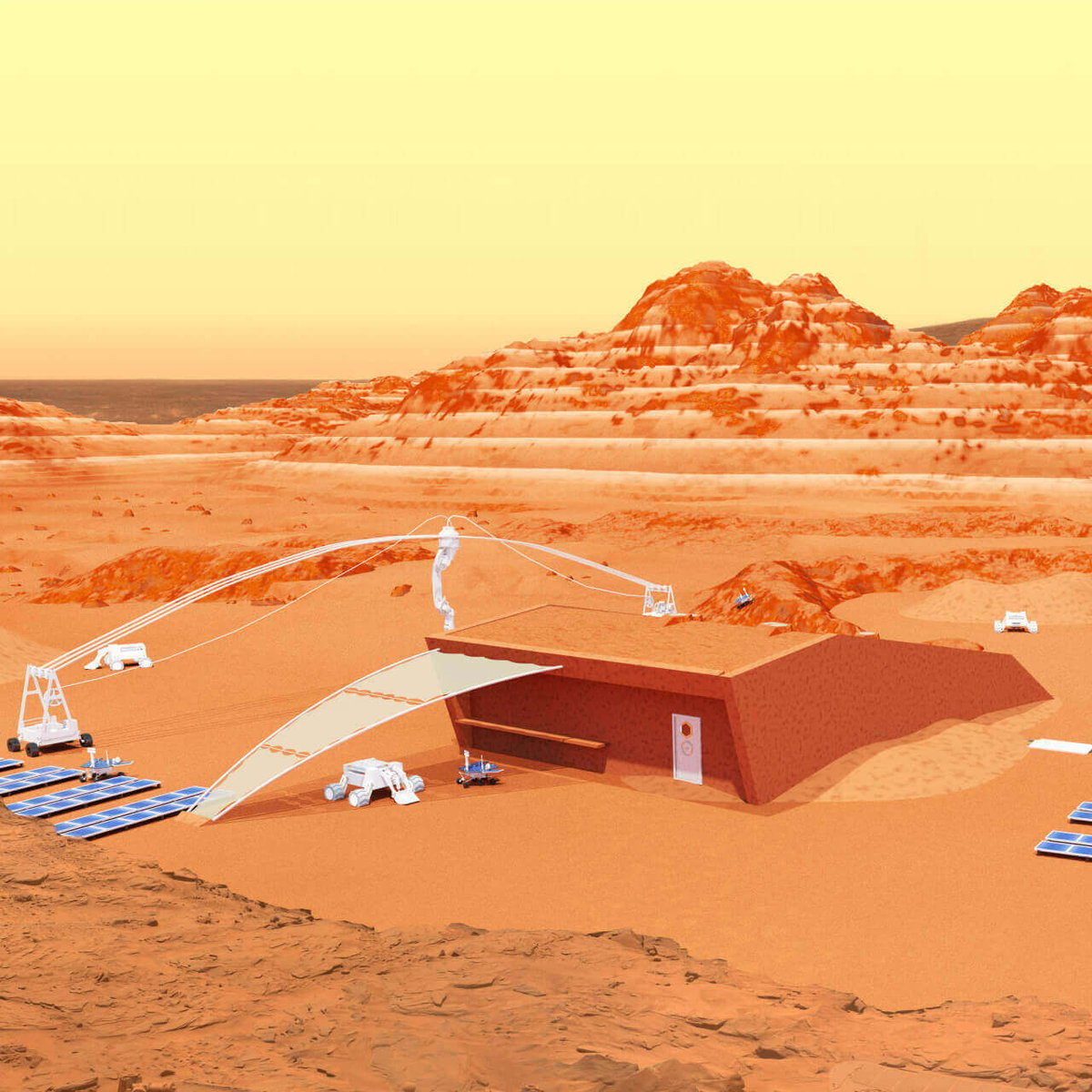

24) RedWorks Habitat

The RedWorks Habitat has been adapted from construction principles of ancient cultures, such as pit houses and pueblos as well as natural constructs like the shell of the nautilus. By 3d printing up from the base of an excavation pit, the Habitat is able to use regolith as an in-situ building material and as a protective barrier from the elements. The internal structure is divided into levels that revolve around a central support shaft like a spiral staircase. The levels serve as a modular design for living space, with each level configured for a specific need. Furthermore, by using organic generative algorithms the shelter’s basic layout can be adapted to produce a suitable structure around existing geological constructs, opening up areas for expanded settlement.

Connect with this team via Facebook, Twitter, Email & at www.redworks3d.com.

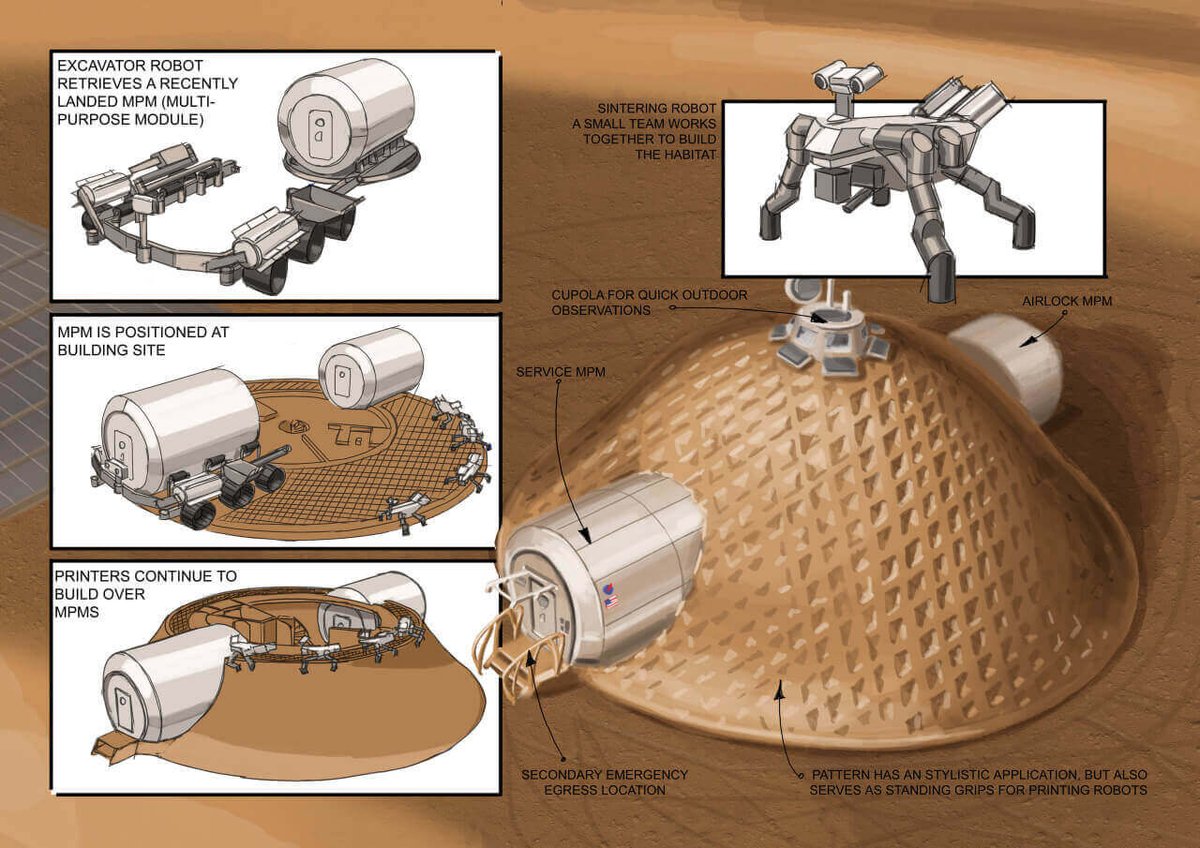

25) MASS

Team MASS is developing a 3D printed Martian habitat using laser sintered regolith. A combination of 3D printed structures using in situ resources and hard structures transported from Earth will be assembled by a swam of robots. Our large earth-moving robots will excavate regolith and move structures into position while legged robots will laser sinter regolith to create the main habitat dome. After construction, these robots will be used to explore the surrounding region. The manufacturing and tele-rob0tic assembly methods are extensible to the building of disaster-response shelters in isolated communities.

Connect with this team via Email.

26) Solar Crafting / Team Neiro

Solar Crafting is a 3D printing technique developed to create off-world structures from indigenous materials. We’ve combined NASA’s latest concepts with the resourcefulness of Solar Sintering and the construction practicality of Contour Crafting to present a new take on off-world 3D printing: the ability to print habitats from Sun and Sand.

Connect with this team via Twitter, Instagram, Facebook, Email & at www.solarcrafting.com.

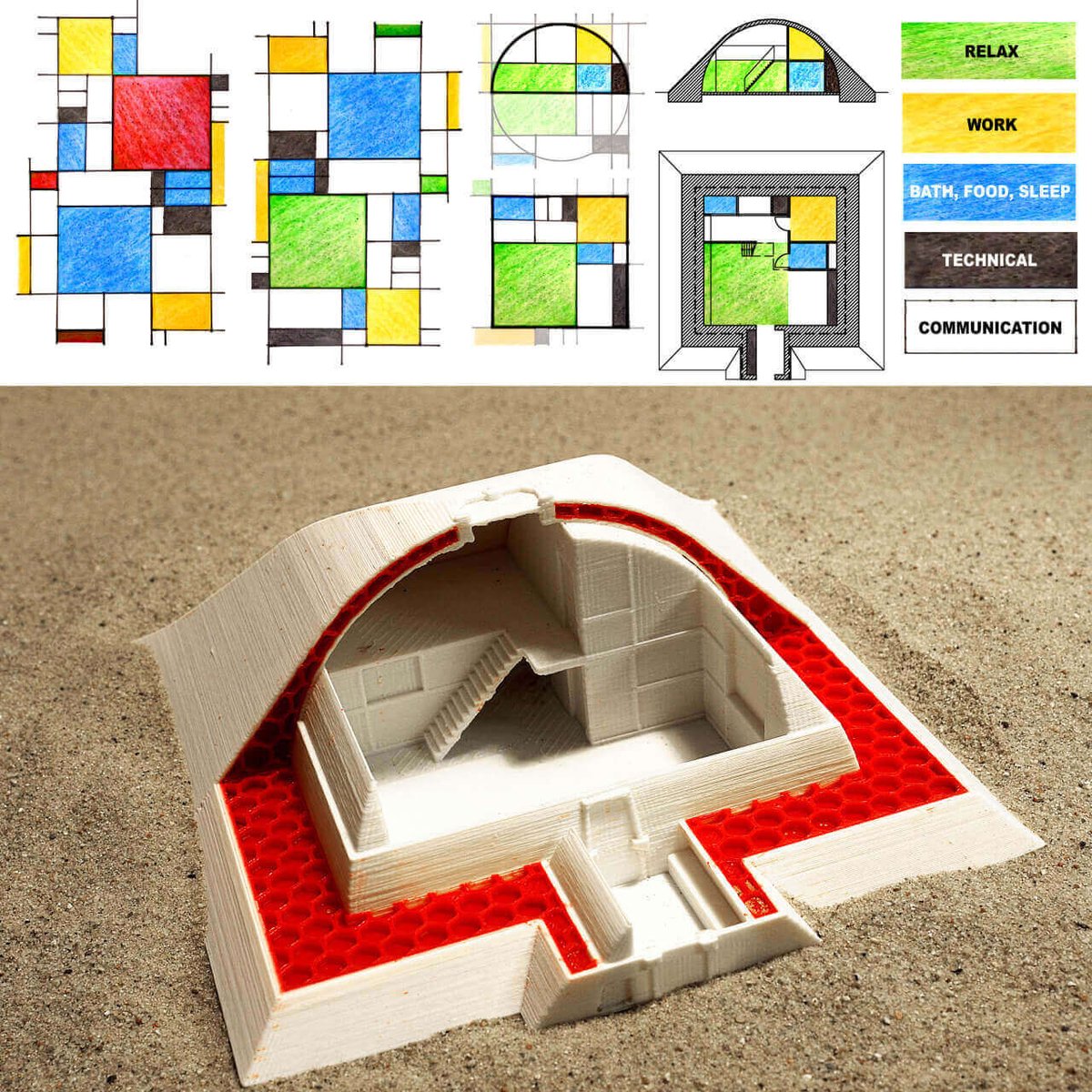

27) SPACE IS MORE Mars Habitat MK2

Space is More Mars Habitat MK2 is a complete proposal of an innovative 3d printing technology and an architecture of the habitat. Construction Technology creates Form that follows well thought, safe and comfortable Function of a martian outpost.

Connect with this team via Facebook, Twitter, Email & at www.spaceismore.com & www.threedemensionslab.com.

28) Ferric Frame / IRONLIGHT

Our 3D printed habitat is constructed using selective laser-sinter printing to fuse local iron-rich sand into composite structures. This eliminates the need for printing feedstock such as filament or binder, allowing for permanent, large-scale structures compatible with the harsh, near-vacuum martian environment. The robotic printing rovers may then be repurposed to extract water from local hydrated clays after construction is complete.

Connect with this team via Instagram, Twitter & Email.

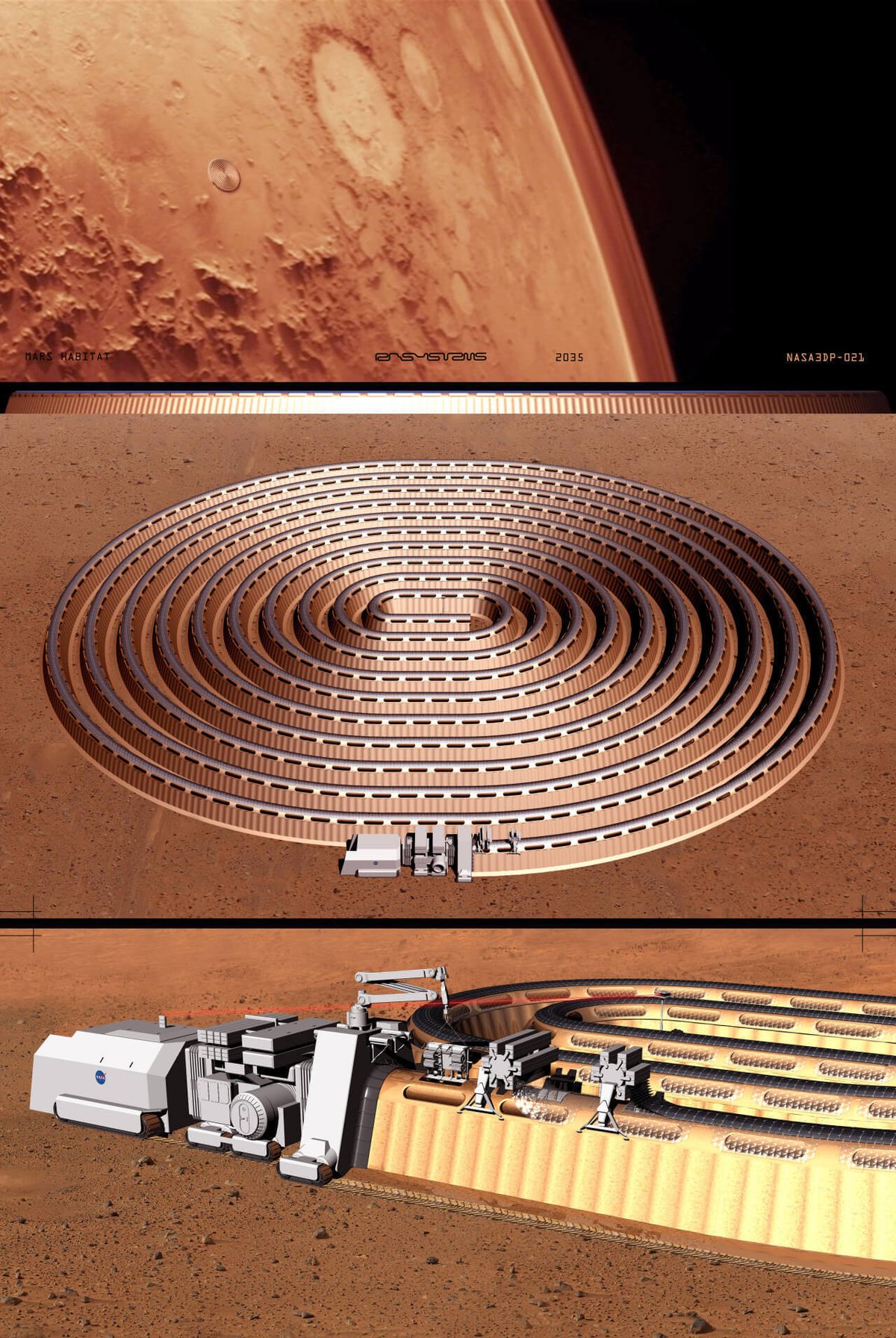

29) Rustem Baishev

One day Mars will become as an ordinary destination as our own Earth’s continents and cities. In such case expandability is the main consideration, for which the most suitable technology should be invented to dictate the design. Given the distance to Mars and roughness of its terrain, the translation of a 3d model from virtual into physical space is a task of an extreme complexity for any positioning and printing method. Therefore, those methods should be as analog as possible.

Connect with this team via Instagram, Twitter, Facebook, Email & at www.rb-systems.us.

30) The Radicle / PARALLAX

The Radicle is a seed for interplanetary colonization. What we have developed is an expandable modular system that when planted, utilizes local resources to grow a base for scientific research and exploration capable of adapting and thriving within the extreme environmental conditions present on Mars.

Connect with this team via Twitter (Twitter 2), Instagram (Instagram 2) & Email.

License: The text of "NASA 3D Printed Habitat Challenge Finalists Revealed" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.