3D Printed Turbopump developed by NASA passes rigorous series of tests. One small step for mankind, one giant leap for cheaper engine parts.

It’s well documented how NASA has enthusiastically embraced additive manufacturing technology. They’ve sent a 3D printer into space, developed a rover with 3D printed parts, and more besides. The latest in a long line of innovations is a 3D printed rocket fuel pump.

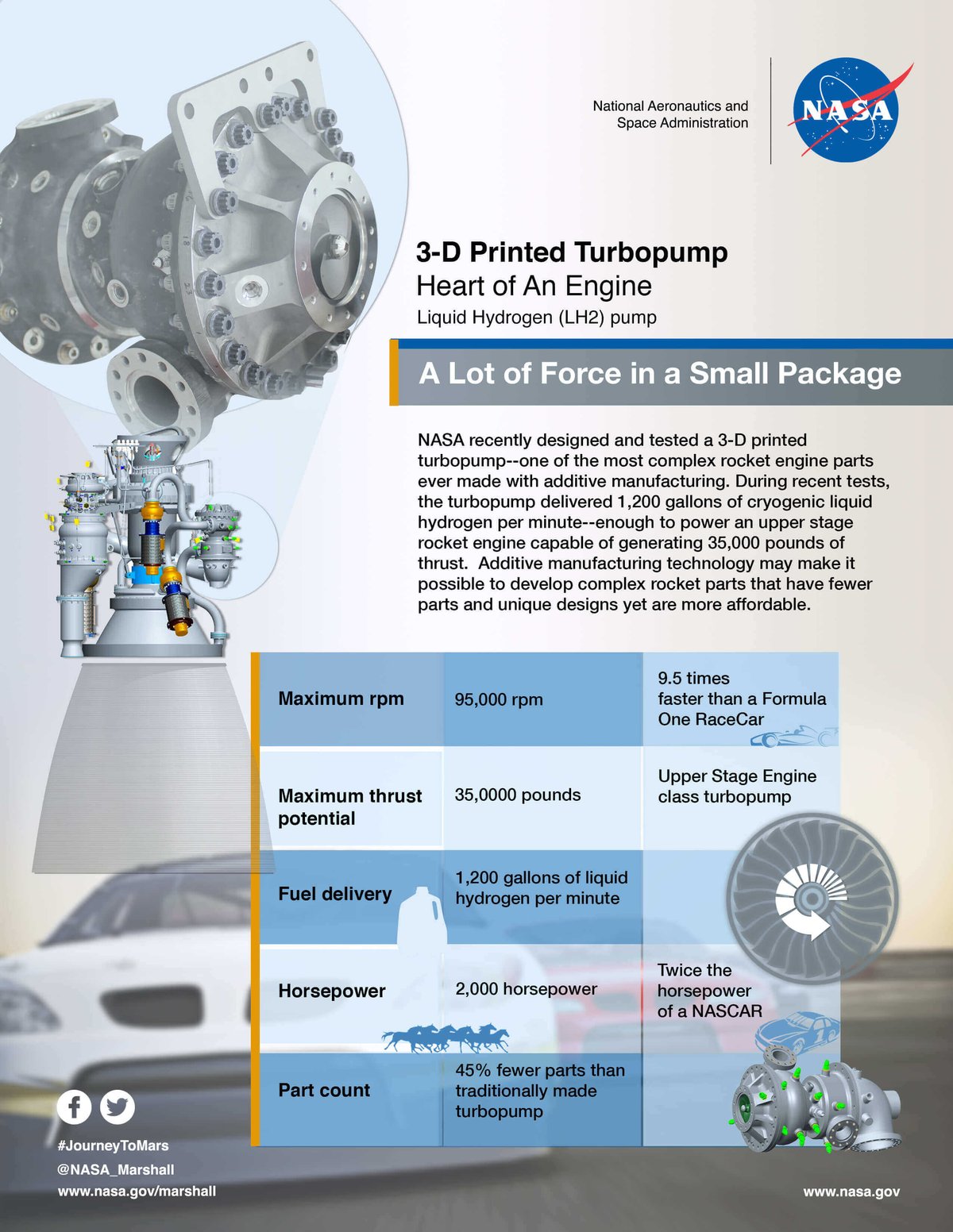

NASA describes it as “one of the most complex, 3D-printed rocket engine parts ever made.” The turbopump is a vital engine part, with a spinning turbine capable of generating over 2,000 horsepower (twice as much as a NASCAR engine).

The ultimate goal of these experiments is that the space agency can dramatically reduce the cost of developing, prototyping and manufacturing their propulsion systems (which already run into millions of dollars).

According to NASA, the pump was submitted to 15 rigorous tests and passed all of them. The turbopump reached full power, delivering 1,200 gallons of cryogenic liquid hydrogen per minute — enough to power an upper stage rocket engine capable of generating 35,000 pounds of thrust.

As for the precise details of these tests, hobbyists and nerds can only imagine what challenges the little 3D printed turbopump was subjected to. We know it survived extreme conditions where fuel was burned at 3,315 degrees Celsius inside a rocket engine, while the turbopump delivered liquid hydrogen cooled at -240 degrees.

For American companies looking into related fields (namely, driving down manufacturing costs for precision parts that meet aerospace standards), the test data is available for review from the NASA Materials and Processes Technical Information System, or “MAPTIS”.

Nick Case, a Propulsion engineer that worked on the project sums up the its importance:

“Our team designed and tested the fuel pump and other parts, such as injectors and valves, for the additive manufactured demonstrator engine in just two years…If we used traditional manufacturing processes, it would have taken us double that time.”

Next stop, a fully functional 3D printed rocket engine, perhaps in use for the long-awaited journey to Mars… Bring it on!

License: The text of "NASA Builds 3D Printed Turbopump Capable of 2,000 HP" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.