NASA’s Jet Propulsion Laboratory is developing 3D printed woven metal fabrics to use within astronaut suits and large antennas.

Whether it’s achieving faster space travel or printing with Martian soil, NASA is constantly on the edge of 3D printing innovation. However, one area that you wouldn’t normally expect the U.S. space agency to venture into additive manufacturing textiles.

But, NASA’s Jet Propulsion Laboratory recently announced the development of advanced woven metal fabrics. The Pasadena, California-based engineering team is creating exceptional functionality where fashion applications usually thrives.

“4D Printing” Textiles From Flexible Metal Materials

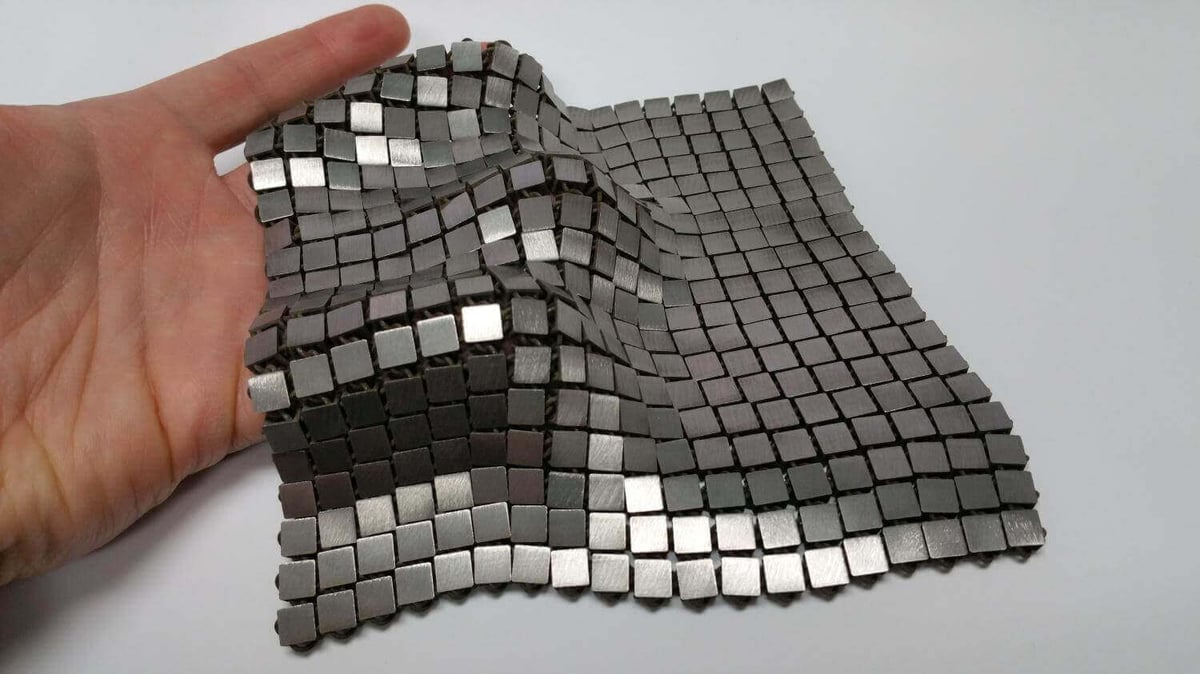

The Jet Propulsion Laboratory is using metal 3D printing to create tiny square textiles that appear similar to chain mail. Although they look as if they’re sewn together by hand, this metallic fabric is actually printed in one piece.

The team in charge of the project are calling the process “4D printing.” This is due to the fact that they can design the geometry and also the function of materials. By delegating how the material will perform once manufactured, NASA hopes to reduce the cost of spacecraft design.

NASA’s so-called “space fabrics” offer four essential functions, including reflectivity, passive heat management, foldability, and also tensile strength. The composition of these metal 3D printed textiles is quite unique.

While one side of the fabric reflects light, the other absorbs it, essentially allowing for advanced thermal control. Additionally, the material can fold in multiple ways and is completely adaptable, but can still withstand the force of being pulled and morphed.

What Might NASA Use 3D Printed Metal Fabrics For?

There are numerous applications that NASA’s latest technology might be compatible with. For starters, astronaut spacesuits could be lined with these metal fabrics. Additionally, 3D printed textiles can shield a spacecraft from meteorites or capture materials and objects from other planet surfaces.

Due to the ability to fold and change shape, other possible uses of this metal 3D printing process includes creating large antennas and deployable devices. One area that NASA imagines immense success is on icy moons like Europa. The engineering team imagines that these fabrics could insulate a spacecraft, while also folding over uneven terrain to prevent the ice underneath them from melting.

Most importantly, “4D printing” metal fabrics also holds the potential to save money on spacecraft designs. This would help push the entire space travel forward into the future. For instance, instead of assembling a spacecraft with dozens of parts, future ships could someday become one entire cloth-like object.

NASA’s Jet Propulsion Laboratory is using 3D printing in a way that could revolutionize the entire space industry. Although it might just seem like fabric on the surface, this metal 3D printing technique could hold the key to unprecedented functionality.

License: The text of "NASA Develops Functional “Space Fabric” With Metal 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.