NASA is 3D printing radiation shields on the Bigelow Expandable Activity Module, an experimental habitat on the International Space Station.

Don’t Miss: 3D Printing for Space: ESA to Open "One-Stop Shop"

NASA has been 3D printing radiation shields using the Additive Manufacturing Facility provided by Made in Space.

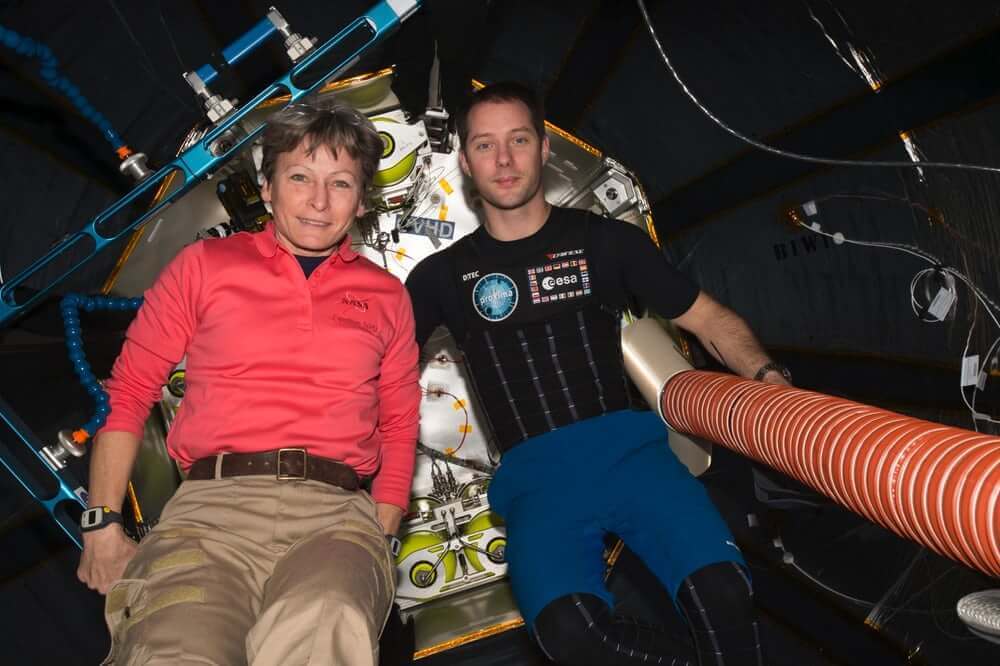

The radiation shields cover one of two Radiation Environment Monitors inside NASA’s Bigelow Expandable Activity Module (BEAM), an expandable habitat technology demonstration which began last year on the International Space Station (ISS).

This week NASA shared an update on the BEAM reaching the halfway point of its planned two-year demo, and it outlined how members of the ISS crew had printed a radiation a shield.

The first shield was printed in April 2017 at 1.1mm thick. Over the coming months this shield will be replaced by two thicker shields. This will determine whether the safeguards work effectively to block radiation. The first will measure around 3.3mm, and the second 10mm.

NASA has Learned Much about Expandable Habitats

First sent into orbit in March 2016, the Additive Manufacturing Facility is now a permanent fixture aboard the ISS. Made In Space owns the 3D printing platform, while NASA and other commercial partners use it as a service.

Over the past 15 months, the Additive Manufacturing Facility has produced a number of complex parts, tools and devices for use on the ISS. The radiation shields are but the latest in a growing list of applications.

The goal with BEAM is to decrease the amount of transport volume for future space missions. Requiring minimal payload volume on a rocket, the habitat expands after deployment in space. This potentially provides a comfortable area for astronauts to live and work. In addition, BEAM provides some protection from solar and cosmic radiation, space debris, and other elements.

This week’s BEAM update highlighted how soft materials can perform just as well as rigid materials for habitation volumes in space. Back on Earth, researchers at NASA’s Langley Research Center in Hampton, Virginia, have been analyzing data from internal sensors, designed to monitor and locate external impacts of orbital debris.

So far they have recorded a handful of micrometeoroid debris impacts. Regardless, BEAM has also performed as expected, preventing debris penetration with multiple outer protective layers.

License: The text of "NASA is 3D Printing Radiation Shields for Expandable Habitats" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.