Nervous System 3D prints mind-boggling (and practical!) porcelain cups using Tethon’s new ceramic resin and shares what they’ve learned.

Nervous System is now among those whose curiosity was piqued by Tethon 3D‘s recently Kickstarted 3D printing ceramic resin, Porcelite, which recently delivered their new product to backers.

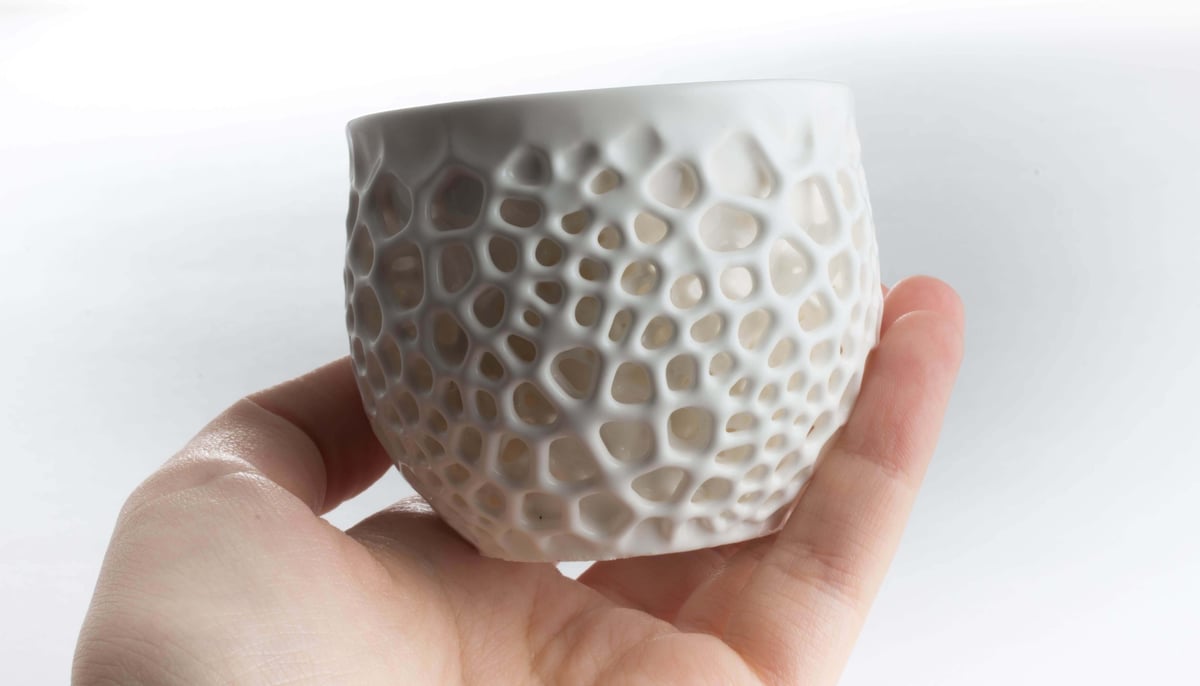

With the resin, Nervous System has created gorgeous porcelain cups in their trademark nature-inspired patterns. The results were a series of incredibly intricate cellular networks, cups that, really, could have been formed in nature. The airy design also allows the structures to remain a reasonable temperature when hot liquids are inside.

Problems When 3D Printing Porcelain

In a blog post, designers say that, while whey are happy with the print quality, it took them over a month of experimenting just to figure out best practices for the Porcelite.

They used their Formlabs printer for experimenting and had to do a lot tweaking. Prints had a tendency to fall off the build plate and from the supports due to the heaviness of the material. To remedy this, they sandpapered the build plate to make it more coarse and adhesive. Other problems included unusually large amounts of shrinkage (17.5% compared to the usual 12% of most ceramics) and materials separating during printing. All of these led to what Nervous System considered the biggest downside to Porcelite: size. With a maximum height just over five inches, there wasn’t much wiggle room or opportunity to work bigger.

On the plus side, they note that the easiest step is actually the final step: glazing. Tethon also recently created a firing schedule to help printers combat bubbles caused by the firing process. Nervous System also posted their step-by-step process.

Nervous System’s Porcelite Ceramic Resin Process

So if you plan to use Porcelite material with your resin 3D printer, these are the settings Nervous System used.

- Print at 50 micron resolution with Flexible V2 settings on a Form 2 (no Open Mode)

- Use 0.9-1.2mm supports

- Roughen build plate with sandpaper

- Set Fine Tuning to -0.2mm platform offset (this may depend on your printer)

- Remove supports

- Post-cure for 2 hours

- Fire to cone 3 with Tethon3D firing schedule

- Glaze and fire as per supplier’s instructions

Though it took some time, new printing processes always take time to master. If gorgeous ceramics are already being created Porcelite, there’s no doubt there’s much more to come.

License: The text of "Nervous System 3D Prints Cups With Porcelite Ceramic Resin" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.