High schoolers at Oakwood School in California learn how to 3D print in a hands-on immersion program. Then they share their expertise with younger students.

New technology, growing minds, students helping other students – that’s what’s happening at Oakwood School in North Hollywood, CA.

To learn to pass the knowledge on 3D printing,Oakwood School in North Hollywood, CA has pioneered a “cascading” approach. This allows older students to share their 3D printing knowledge with younger students.

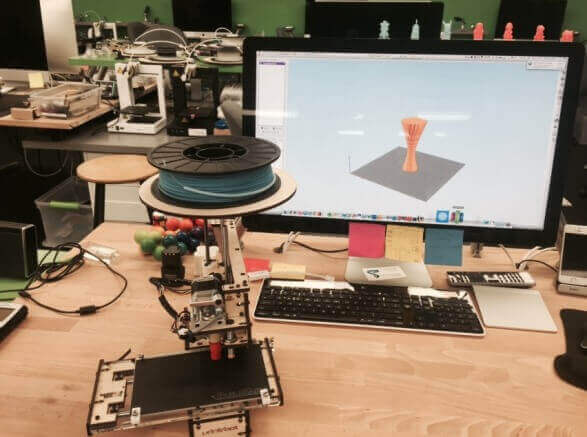

First, high schoolers build their own Printrbot kits to understand the mechanics of the technology. To control all the aspects of their printing, they are using Simplify3D software.

After developing a solid foundation, the high-schoolers share their knowledge with other Oakwood students in the school’s Immersion Program. In this intense two-week program outside of their regular academic schedules, students refer to the process of sharing their expertise with other groups as “cascading knowledge” or “transfer of knowledge” – you might know this principle from Montessori schools.

How 3D Printing In Classroom Started Out

It all started when Oakwood instructor Marcos Arias was looking to bolster opportunities for his students in the fields of engineering, architecture, and design. As Marcos explained, “My department is constantly changing. To stay relevant with new technologies, I spend a great deal of time researching what studies we should add next, and 3D printing was on my radar.”

Marcos enlisted the help of an interested student, and together, Marcos and Lucas P. tested whether an Immersion Class could be structured around 3D printing.

Over the summer, Marcos gave Lucas a Printrbot Simple kit along with a challenge: could Lucas build the kit himself and produce successful 3D prints?

That summer, Lucas worked diligently to build his 3D printer. With minimal prior knowledge about 3D printing, he mostly relied on guidance from the Internet to run his printer. Lucas finally completed the first print on his newly built Printrbot late one night that summer. “It was all wiry and the layers weren’t sticking,” said Lucas, “But I thought to myself that even if this is the best my printer can do, this is still the coolest thing I’ve ever done.”

After understanding the problems that Lucas encountered, Marcos understood that he would need a more predictable learning experience for a two-week immersion class to be successful. As Marcos explained, “The learning process would not be as powerful without this construction and experimentation component.”

The Demand Already Triples The Capacity Of the Classroom

The next thing was software. Marcos researched options and determined that he needed software that was flexible and easy to learn, but that would still allow the students to have full control over all their print settings. As Marcos explains, “Simplify3D met and exceeded all of these requirements. My students have what they need for an easy startup experience, but they also have the software tools to advance to more complicated printing projects.”

After the high-schoolers build and master the use of their Printrbots, they act as Teaching Assistants for the next Immersion class of seventh, eighth, and ninth graders.

The class has gained so much popularity among Oakwood students that signups for this academic year were more than triple the program’s capacity. Luckily, there are plans to add a “How to Build a 3D Printer” camp during their summer program in 2016 to accommodate additional students.

License: The text of "Oakwood School Lets Students Build Printrbots" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.