The Cosmetic Science Research Group at London College of Fashion is using 3D scanning and printing to create personalized lipstick applicators.

As 3D printing takes the fashion world by storm, researchers from the Cosmetic Science Research Group at London College of Fashion are working on a way to incorporate additive manufacturing into beauty products too.

As most women know, lipstick is very personal. From getting the right shade to choosing matte or glossy, etc., every woman’s preference is unique. Plus, every woman’s mouth is also a different shape.

Now, researchers at the Cosmetic Science Research Group argue that the applicator itself should also be personal.

And why not? Their idea is to create a more convenient way to apply lipstick instead of the standard swivel-up tube.

By using 3D scanning and printing equipment, they’ve developed a new personal applicator that works better.

“The lipstick applicator is used by pressing the sculpted lipstick surface to the lips that deposits a uniform coating of the lipstick, thus removing the need for a mirror,” the researchers explain.

Creating Lipstick Applicators with 3D Scanning and Printing

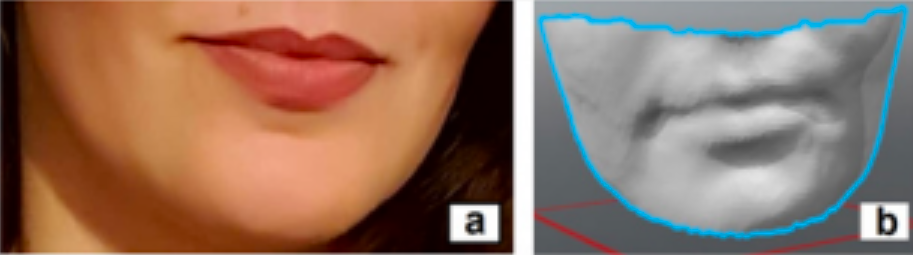

They decided to create a lipstick mold, base and cap for the applicator. In order to create a 3D printed applicator, the researchers need to first scan the lips of the participant.

Next, they created a profile with the data. The researchers then transfer the digital image model of the lips to Autodesk 3ds Max for modeling and optimization.

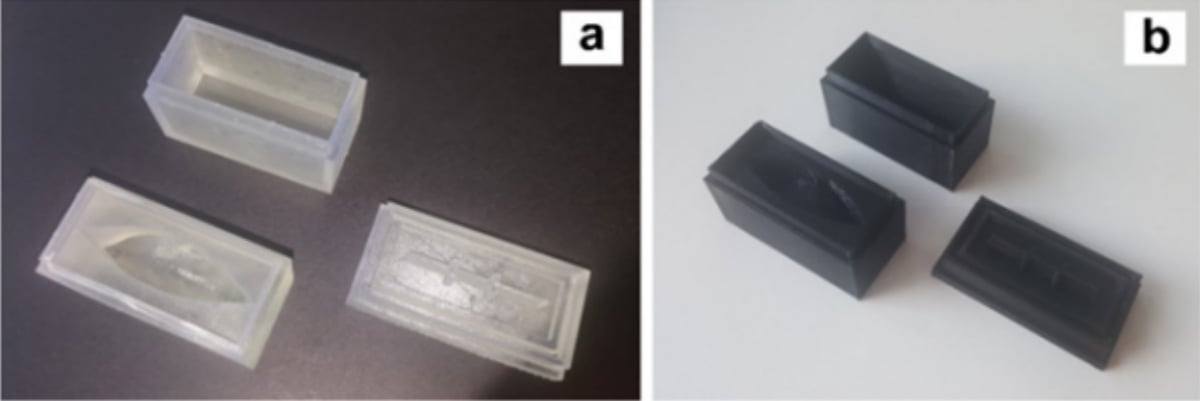

To find out which one created the best personalized applicator, the researchers explored two 3D printing techniques and three different materials.

They tried Acrylonitrile Butadiene Styrene (ABS), Polylactic acid (PLA) and a clear Formlab resin. For the 3D printing processes, the used Stereo lithography Technology (SLA) and Fused Deposition Modelling Technology (FDM).

So, they began testing SLA and FDM to create the components. They used ABS and PLA for the FDM printer and Clear V2 Formlab resin with the SLA printer.

Last, they filled the molds with lipstick and put them in the fridge. However, after removing the molds 15 minutes later, the researchers found that there was only one clear winner.

The PLA applicator was the only one to properly detach from the lipstick every time.

When the woman simply presses her lips to her personally sculpted mold, it perfectly deposits the correct amount of lipstick.

Apparently, the most obvious benefit of having your own 3D lip scan is that you don’t need to find a mirror anymore since it’s perfectly shaped to your mouth.

“It was shown that a novel, bespoke, cosmetic product for the lips a personalized lipstick applicator, can be produced successfully using 3D printing technology,” the researchers conclude.

Would 3D printed lipstick applicators really make a difference to your beauty regimen or would they be too expensive?

It’s hard to say at this point. Like many things in fashion, it may take awhile before it’s available to the rest of us.

Source: Med Crave Online

License: The text of "Perfectly Personalized Lipstick Applicators Created Using 3D Printing Technology" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.