Why you should read this: Because your next delivery might be 3d printed “on the fly”.

Come along ladies and gentlemen. Take my hand and let’s imagine worlds that were and yet may be. Let’s tread the line between science fiction and science fact. Let’s look into our crystal ball to see what the future may hold…then we’ll go out for scones and a latte.

Delivering things has always been a labor intensive job. Whether it’s a single person carrying a parcel, a horse pulling a wagon full, or trains, planes, and automobiles moving packages and letters around the world, a lot of energy and time (not to mention natural resources) goes into getting you what you want. Entire industries have been developed and perfected to link people in all corners of the globe with the things they need.

The advent of the internet and the rapid implementation of e-mail and digital products has moved delivery into a new realm but the vast majority of products are still conveyed manually from here to there. Soon, though, may come a time when the internet is much more than just a medium for documents, software, music, and movies. The days are rapidly approaching when you can have delivered direct to your house – via digital, not manual conveyance – a real and tangible paper-and-ink book, a garment just your size, and even a piping hot pizza with all the fixin’s. This is where we tip toe over the line between science fact and science fiction so hold on tight.

How is this digital delivery of real, physical items possible? Two words (or is it a number, a letter, and a word or a number, an abbreviation, and a word?): 3D Printing.

It’s really not as far-fetched as one might think.

The Future

1. The nature of 3D printing

3D printing, coupled with the reach and speed of the internet, is the ideal medium for delivering any and every sort of good imaginable. It’s really already set up to do so.

At the most basic level, 3D printers use digital files – like a standard Word or Excel file – containing all the specifications and instructions necessary to recreate the item on your own personal 3D printer or on your friends printer on the other side of the globe. All that’s required for the next stage in delivery is to connect the 3D printer to the internet.

Many 3D printing companies already participate in a form of digital delivery by allowing you to download the plans for a given item right to your computer. It’s not such a leap to envision a time when clicking ‘Add to Cart’ and ‘Proceed to Checkout’ result, not in a 3 to 10-day wait, but in a 2 to 3-hour wait.

2. Materials

The only major thing holding back 3D printing right now is:

1) the materials, and

2) the ability to print in multiple materials at the same time.

To point one, new materials are being developed at an alarmingly rapid rate. Only a few years ago, 3D printing was restricted to plastics and metals. Now, 3D printers can compose with wood, paper, heavy metals (e.g., bronze, copper, and brass), food, and even human tissue. Printing with breathable, wearable fabrics could revolutionize the garment industry. And think about your cell phone for a moment. It’s composed of mainly plastics and metals with perhaps a dash of glass thrown in for good measure. Those first two components are already old hat for most personal 3D printers. All it would take is the ability to print with glass and you could 3D print your own iPhone.

That brings us to point two and the real technical advance that must take place to make 3D printing viable as a means of delivery: printers must be able to build in multiple materials at the same time.

There are a lot of useful 3D printed creations out there but all of them are composed of only one material. Sure it’s possible to print the smaller pieces of a larger object out of different materials but, honestly, how is that different than the current methods of subtractive manufacturing? There’s no real innovation in that other than the fact that additive manufacturing the parts may cost less. The real quantum leap in manufacturing would be to compose/print/build (whatever you want to call it) a complex item (like a cell phone) without the need for assembly – build it from the platform up using plastic, metal, and glass so that when the printing process is complete, the item is ready for use. Additive manufacturing has the potential to be that quantum leap.

So, again, imagine you want to buy that new bestseller. You haven’t quite gotten used to reading on a tablet and you like the feel of holding a real book in your hand. With the internet and 3D printing, you’ll be able to purchase the book, print it on your own personal 3D printer, and read it – all in a matter of hours.

The Present

You’ve probably heard the news that Amazon.com was toying with the process of using drones to deliver packages. That’s all well and good but it’s really just a refinement on the manual conveyance of packages; it’s really no different than using a truck or a bike to deliver.

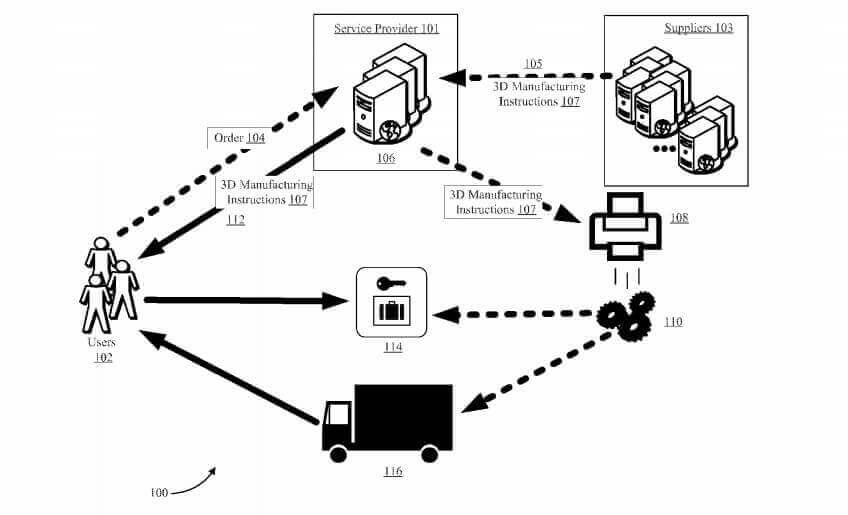

But recently, Amazon filed several patent applications for a mobile, on-demand 3D printing service. That’s right, Amazon wants to put 3D printers in their delivery trucks. Add to that the fact that both UPS and FedEx have incorporated 3D printing stations in their stores to capitalize on the growing market. Can you feel the science fiction turning into science fact? I can.

As 3D printing technology continues to grow and as more and more people have user-friendly 3D printers in their home, we creep closer and closer to the time when UPS and FedEx no longer operate a fleet of trucks and planes and instead rely on digital, rather than manual delivery to keep the world running.

Ah, that was fun. Did you enjoy yourself? I certainly did. Now, how about that latte?

License: The text of "The (possible) future of order delivery" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.