To produce an affordable and innovative range of prostheses, new company Protosthetics is using Lulzbot 3D printing and software solutions

Don’t Miss: LulzBot Mini Review: This Mighty 3D Printer Does the Job

Using open source hardware 3D printers from Lulzbot, fledgling startup Protosthetics is bringing a range of affordable prosthetics and orthotics to market.

Nearly a dozen LulzBot printers are in operation at the Protosthetics headquarters in Fargo, North Dakota. These printers are primarily for building sockets that are specific to the customer’s measurements.

Josh Teigen, “Chief Visionary” at Protosthetics, says:

“The benefit of having the LulzBot 3D printers for us has really been the fact that not only are they a high-quality, very robust machine to start with but the community and the Open Source nature have allowed us to basically build on top of that and incorporate our own characteristics and functionality. Having the support behind that has been one of the biggest keys to our success as a manufacturer in being able to actually deliver clinically relevant products to our customers.”

With this approach, Protosthetics is able to fabricate activity-specific attachments and accessories to positively impact patients’ lives. The Protosthetics Amphibian Leg, for example, is a durable and waterproof prosthetic made with NinjaFlex flexible material. A big advantage of the Amphibian is that it can be worn in the shower and other wet environments.

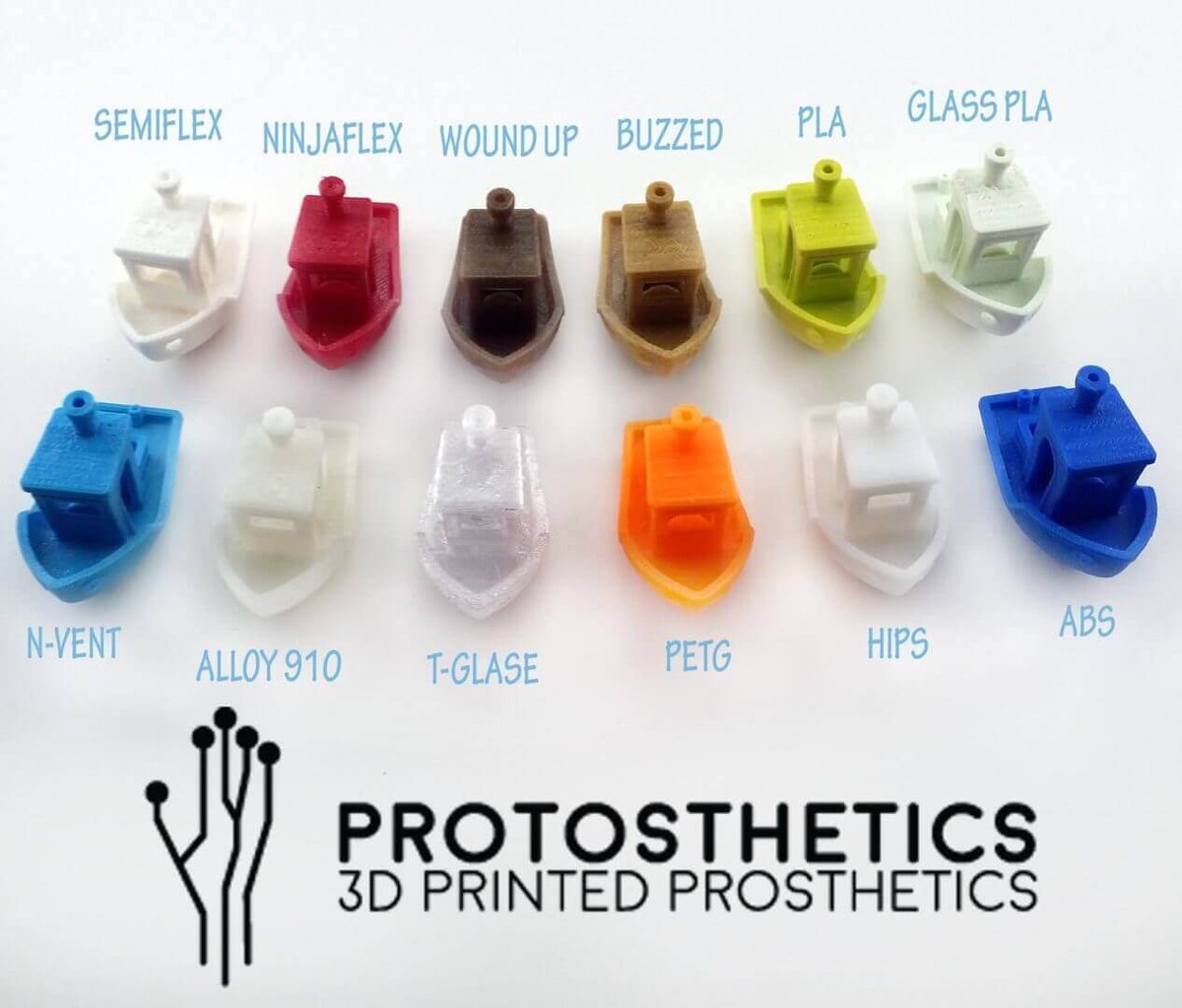

Below is a sample of the different materials that Protosthetics are able to manufacture their prostheses with. Each offers their own distinct mechanical properties and benefits.

Protosthetics Advancing the Medical Industry with 3D Printing

The team at Protosthetics attest that the LulzBot edition of Cura software has been integral in the design of their range, citing efficiency and ease of use for the speedy and accurate production of parts.

According to Cooper Bierscheid, “Chief Futurist” at Protosthetics:

“For the average user, it’s some basic settings, but then you can expand it to really make it do a lot more things. I think it’s pretty fast and efficient of generating the GCODE, and I really like the feel of it.”

Protosthetics also highlights the quality of the documentation that comes with the printer, such as the instructions and user manual. And the open source nature of the machines provides the company with greater freedom if preventative maintenance needs to occur.

Overall, the LulzBot platforms have enabled significant advancements to Protosthetics’ workflow. What this means is that patients are receiving an enhanced level of care with more reliable, durable prosthetics.

And with that, the last word goes to Bierscheid:

“You’re able to get your idea out of your head and into the physical world and reiterate that process over and over, and it really alleviates a lot of the costs in rapid prototyping those different devices and coming up with new devices that help people and then eventually moving into the final products that help people.”

Source: Lulzbot

License: The text of "Protosthetics are 3D Printing Affordable Prostheses with Lulzbot" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.