Printrbot CEO and founder Brook Drumm speaks to ALL3DP about his plans for the company, and the current state of the 3D printing industry.

Brook Drumm is a lively and charismatic figure in the maker scene, occupying an important role as the owner and CEO of Printrbot. Located in Lincoln, California, his company was founded in 2011 with the launch of the original Printrbot on Kickstarter. They have since released a range of machines that are often called the best budget 3D printers on the market.

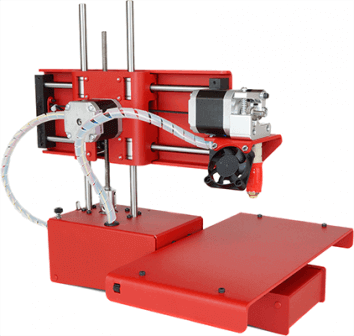

With the recent launch of the Printrbot Play, for example, the company has furthered its reach into the affordable, entry-level 3D printing consumer segment. Costing only $399, the Play provides quality and ease of use comparable to other 3D printers costing hundreds of dollars more.

ALL3DP contacted Drumm for a Q&A about his exciting plans for the future of Printrbot, and his thoughts on the current state of the 3D printing landscape. As always, he provided some interesting answers.

Q: According to press clippings, you were once a pastor, and then a web developer. What inspired you to move into 3D printing?

My whole life, I’ve been a maker and a techie. Even as a pastor, I pursued these passions. Natural drift into more and more tech sent me to start a web company that eventually bored me b/c and led me to pursue more making… I chose 3D printing. The Kickstarter hit and boom – PrintrBot was born. My entrepreneurial nature figured heavily into my path. One interesting realization was that my people skills learned and experienced through my pastoral roles was a perfect training ground to put teams together and lead… As well as dealing with the public and public speaking.

Q: Following in Printrbot’s footsteps, it seems like a new 3D printer is being launched on Kickstarter every week. Do you have any concerns about the quality of these printers?

The real problems new 3D printer companies face are inexperience and a lack of innovation. I don’t think there is anything new in FDM printing. Low price points are a huge business risk. Lack of skill and experience are business killers. Buying a printer from an non-established company at any price is a risk and equal or better products are already available from established companies with good track records. I faced all these challenges but not only overcame them, my timing was right. Call it blessed or call it luck, the timing was nothing I or anyone can control. It will take a product exponentially better to break out of the noise that is out there right now.

To your point though, yes, quality is a huge issue for new companies and especially Kickstarter printers at low prices. Quality of the product and customer service.

Q: What does the future hold for Printrbot? New kits? Bigger build volumes? A departure from 3D printing entirely?

We are happy with our core printer product line up. The Printrbot Simple will undergo some cosmetic changes to utilize standardized parts. We have made steady progress on cost and margins as well as quality so our printer line is very stable. We will continue to pass on savings to customers to stay competitive. We continue to absorb more manufacturing in house to cut cost and expand our capabilities. This leads to lower cost over the long haul.

Our filament prices have been an area of focus and even smaller, less expensive spools are in the works. People want more options with less overall investment.

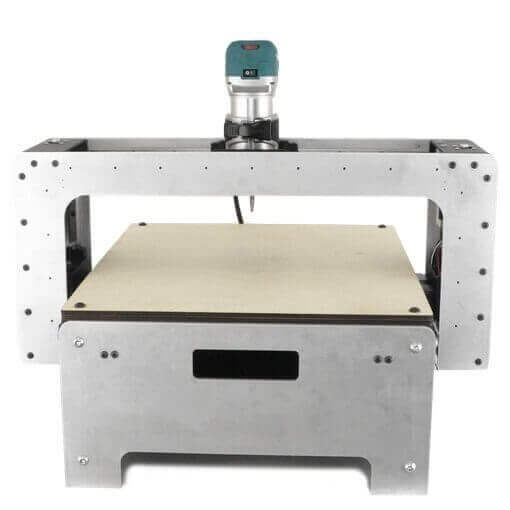

Our Computer Numerical Control (CNC) line is about to go into high gear. We have two promising CNC machines with more in the wings. We are experts at hardware, electronics and, now, software. This opens up a variety of machines, including plans for a laser cutter. We love tools and makers, so we make what we want to use.

Software is easily our biggest investment of money and resources to date. Our printer software is close to release and the infrastructure will lend itself to the CNCs and laser cutter too. This was the missing piece for Printrbot and it’s about to happen! We think it will be somewhat disruptive. No company, to my knowledge, will be our equal in terms of breadth of software platform + hardware offerings. It’s very exciting.

Lastly, our new Surface Mount Technology (SMT) electronics line is up and manufacturing printrboards. No printer company our size has this and it will also give us an edge in the maker community. There is no limit to what we can produce even in terms of maker projects… And 100% in-house. Who has the capability to do electronics, injection molding, folded metal, machining, printed parts and software under one roof?!

Q: As a leading figure in the Maker movement, do you feel pressure to live up to people’s expectations?

No. But that’s easy for me to say because I’m already an extremely nice guy 😉 I am genuinely honest, moral, generous, and I love all people. That’s not a brag, just ask anyone who has met or knows me. It’s easy to live up to high standards when that’s actually the way you live anyway. I don’t have secrets in any part of my life so I’m just myself and that’s enough.

The only sticky points are a couple of areas that I break the mold of people’s assumptions and expectations. Namely, I am fearless to speak my mind. I am a natural skeptic. I am extremely conservative – which comes as a surprise in tech & business circles. I’m also overly confident and that comes off as egotism at times… And is fair, BTW. I like beer but enjoy in total moderation – not all parents or conservatives get on board here.

Like many who have been thrust into the public eye, I do find myself becoming a bit of a recluse. I can be in the public for short stints, but it wears one down and I need to retreat and recover. The tumultuous life of a startup CEO is draining and, add to that being on television, it leaves my pretty stressed. I recognize I swing between high highs and low lows, so I’ve had to learn to deal with this crazy lifestyle.

To fans / community members, or even naysayers, I recognize I am a polarizing figure. Most either love or hate me. I kinda dig that. I usually know where I stand.

Q: How do you think we can overcome the knowledge gap between 3D printing best practice and public awareness? Or is 3D printing destined to remain a hobbyist pursuit?

We must lower the technical hurdles to move from hobby to commodity. Both are terms with downsides. My particular goals are centered around bringing these maker-technologies to the masses. We will move past hobbyist eventually, but I want to be clear that I think a 3D printer will be in every home someday. My business decisions are centered around that goal so it’s a long game… Maybe very, very long.

Pushing through this present trough of despair (don’t remember if that is the proper term) is the most important hurdle right now. I focus on near-term in my day to day, so survival is paramount. After survival, the competition will get ugly, I predict. There will be many casualties. Emerging as leaders, a few companies will carve out niches and gain the public trust. Establishing this trust and extremely high quality products at compelling price points is the goal. Ease of use is making great strides at Printrbot and a couple other companies. This will fuel adoption.

Q: You’re listed as an author on a new book called “Make: 3D Printing Projects“. Can you tell us about your contribution? What’s your chapter about?

I did a project called SkyCam, a strangle little robot that travels on a string, rope or wire to look around with a Raspberry Pi / camera. It’s wonderfully odd and really pressed my coding and electronic skills. The design was easy, but as usual, I bit off a lot to chew. It can and should be the basis to make all sorts of curious robots for someone wanting to learn Raspberry Pi robotics.

A few of my employees also contributed, so I paid them to take time to design and develop. Their projects probably are better than mine and I did get their help in mine too do it was s group effort!

Q: Which new developments in the 3D printing industry are you most excited about, currently?

I am most excited about our software that is about to drop. It will slowly bring together our product line in a way no one else has yet.

Alongside software, we are working on a big switch to TinyG as our controller electronics in all – yes, all – of our machines. A unified electronics / firmware / software platform is unprecedented. Our software will do things never before possible in CNC and laser cutters, but will bring new ease of use in our 3D printers. All machines will communicate directly with the cloud. Projects can be shared and not just printed projects, but projects that span 3 or 4 categories of devices: 3D printing, CNC, laser cutting and electronics. Hopefully, we will see a killer app for 3D printing emerge: as a useful tool in any project involving these forms of manufacturing and making.

Q: Can you tell us about the partnership with AutoDesk Fusion 360? How will your customers benefit from this software?

We use it and love it. So we endorse it. I endorsed it before I got any benefit from doing so. It’s not about money or marketing. It’s a great tool for makers. Autodesk has skills that span across all our present and planned machines: design. It’s a good match.

I’ve been very up front with them about my nervousness about Spark. It could be awesome, it could be an emerging monopoly in the platform space. The later scares me. But even if they crush us on the software ecosystem battle field, the makers out there will benefit, so I’m OK to proceed. I still haven’t used Spark, but it is definitely a competitor with our planned software offering. Competition is good though – it makes you awesome or it kills you and if it does, you may just deserve to die.

Q: You’ve stated that you don’t like working with ABS filament, and PLA is your preference. Are there any other types of filament you would recommend?

All materials have their place. I’m a pragmatist so PLA works almost every time. I love nylon and other expensive exotics that are pretty or strong, but I don’t have to pay to play, so I’m not a good one to ask.

Chasing all the required settings to get good prints from all materials is a pain in the butt but rewarding if money is no issue.

I especially hate the price gouging going on in the materials space – especially closed (chipped) filament. It’s ridiculous and I must crush them. 😉 So I am attacking with low prices, 100% guarantees and great service. Hope it works!

Q: Finally, what’s the single most useful thing you’ve ever 3D printed?

I like useful things so I print a lot of them. My iPhone case done in oddly pink-red ninja flex is with me 24/7. It’s boring but saved my phone so many times.

I love things that move and kind of hate static do-nothings, so I don’t print stuff to put on the shelf. I’d rather not print anything until I find something complex and difficult or something useful that has a purpose.

My useful printed items are sometimes simple, like a washing machine knob, a shelf support, a fix for something broken, a charging stand, a Raspberry Pi case, a robot, or a key for my back door.

The most useful use is prototyping my machines that I will produce in metal or injection molding. We constantly print product beta parts. It’s a huge money saver.

License: The text of "Q&A with Brook Drumm, Printrbot Founder and CEO" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.