Researchers at Rice University hacked a commercial Laser Cutter to create a cheap, open-source SLS 3D Printer for regenerative medicine and experimenting.

Selective Laser Sintering 3D Printers are not cheap. These are the heavy duty printers that create many of today’s most sophisticated prints for industrial and research applications.

Jordan Miller, assistant professor or bioengineering at Rice University says, “SLS technology is perfect for creating some of the complex shapes we use in our work, like the vascular networks of the liver and other organs.”

That’s why bioengineers at Rice have hacked a commercial-grade CO2 laser cutter, and turned it into an open-source Selective Laser Sintering 3D printer.

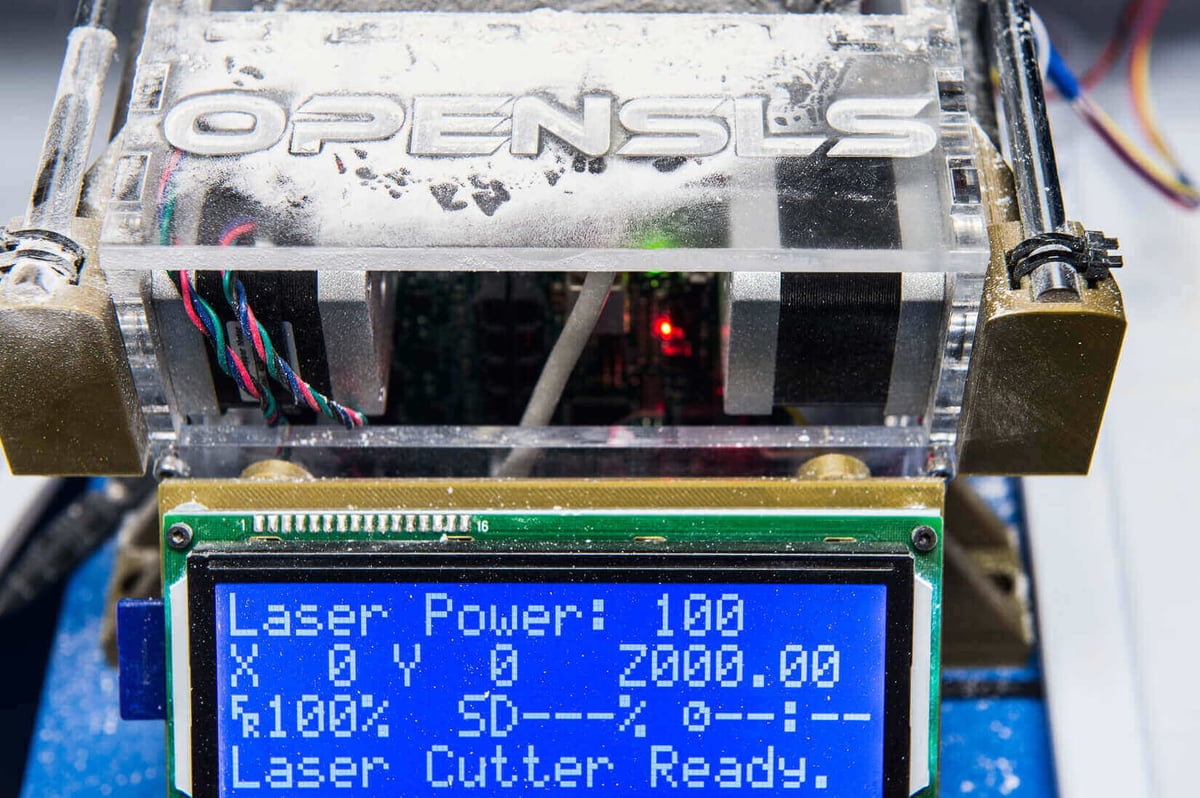

The powerful “OpenSLS” printer costs 40 times less than commercial counterparts, and is open source. Using low cost, open-source microcontrollers, the team was able to build their printer for under $10,000. For comparison, though SLS technology has been around for decades, the typical commercial SLS platforms start around $400,000 and go up to $1 million.

“You can actually cut most of the required parts with the same laser cutter you are in the process of upgrading,” said Miller. “It’s around $2,000 in parts to build OpenSLS.”

Using Open-Source SLS 3D Printer for Medical Research

The idea of hacking a commercial CO2 laser cutter started back in 2013, largely because laser cutters have highly precise laser control, and roughly the correct wavelength of laser. Now, the team has achieved the goal of not only creating an affordable SLS printer, but sharing it with the community.

From the outset of the project, the aim was to bring this technology to other labs, by making their work easy to reproduce. All of their hardware designs and software modifications can be found on GitHub.

The defining feature of the OpenSLS is its compatibility with so many different types of powdered material.

Researchers on the project had success with nylon powder and polycaprolactone (PCL), a nontoxic polymer. This adaptability gives users the flexibility to experiment with different plastics, and also biomaterials for regenerative medicine.

In the future, perhaps the OpenSLS will not only let scientists and hackers play with new materials, but discover incredible, new usages for printing in the sphere of medicine.

Check out more details in the video below, and the complete paper can be found on PLOS ONE.

License: The text of "Laser Cutter Converted into Open-Source SLS 3D Printer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.