Can a 3D printed superconducting Cavity help researchers study the speed of light? Researchers at the University of Melbourne say “yes”.

Studying the universe in depth requires the most expensive and complicated technology — or does it? 3D printing isn’t just developing at the speed of light, it can help study it, too.

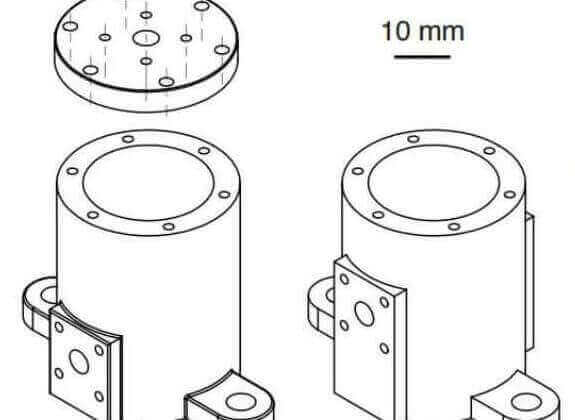

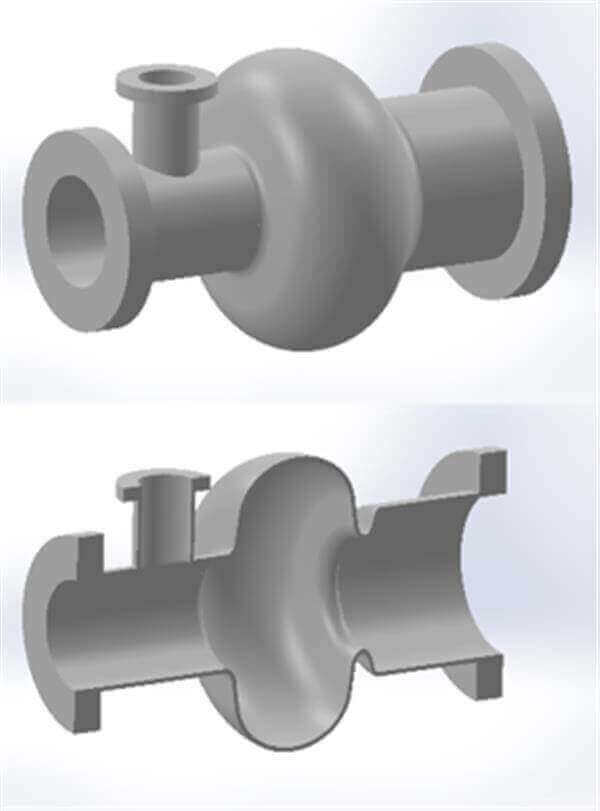

Physicists at the University of Melbourne, led by Daniel Creedon, have been using superconducting microwave cavities. These cavities are a resonator for particle waves, that confines electromagnetic fields – usually microwaves are used. These “boxes” act similar to an organ pipe or sound box of a musical instrument.

The manufacturing process for such cavities is usually expensive and complicated. Creedon and his team, however, have designed and tested a 3D printed superconducting cavity for the first time.

The number of superconducting cavities in research projects is growing rapidly. They work by capturing and retaining microwaves, increasing the amount of time researchers have to study certain phenomena — for example, the speed of light. Despite their growing popularity, the cavities cost remains high, given the complex shapes required. It’s vital that all parts be high quality and perfectly formed, or researchers could end up with boatloads of false information. Need high-precision at a low cost? Sounds like a job for 3D printing.

3D Printed Tech to Make Researchers Rejoice

This new development has two major implications: first, this means a new generation superconducting components that are easy and affordable to print. Given just how much more customizable printing is than traditional manufacturing, it will likely lead to brand new tools and methods for studying the universe.

It also marks the first studies of 3D prints’ electrical properties. Namely, aluminum powder isn’t the same of standard industrial aluminum. The powder generally contains some 12% more silicon than other manufacturing methods. Testing their 3D printed prototype, researchers confirmed that the difference in silicon had no noticeable effect on results.

Surprisingly, Creedon’s team isn’t quite done. They want to use purer aluminum to create even better cavities. Plus, they believe they can create “cavities that are impossible to manufacture using conventional machining techniques.”

If these guys think 3D printing can do the impossible, it sounds like a sign of good things to come!

Find the original paper here, or watch Bill Nye talk Superconductors printable future above!

License: The text of "Researchers Develop 3D Printed Superconducting Cavity" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.