VHM Fonderie uses Stratasys’ PolyJet 3D printing technology to create master models for the sand casting of manufacturing tools.

While 3D printing is used for a vast range of applications and prototyping purposes, the production of heavy duty manufacturing tools are still left to industrial methods like sand casting. But that doesn’t mean that 3D printing technology can’t have an impact on the workflow of these advanced casting processes.

The French foundry and machining company VHM Fonderie has fully integrated Stratasys’ PolyJet 3D printing technology into their production workflow. The company, formerly known as Heinrich Fonderie, has merged 3D printing with traditional sand casting to create industrial iron castings for manufacturing tools.

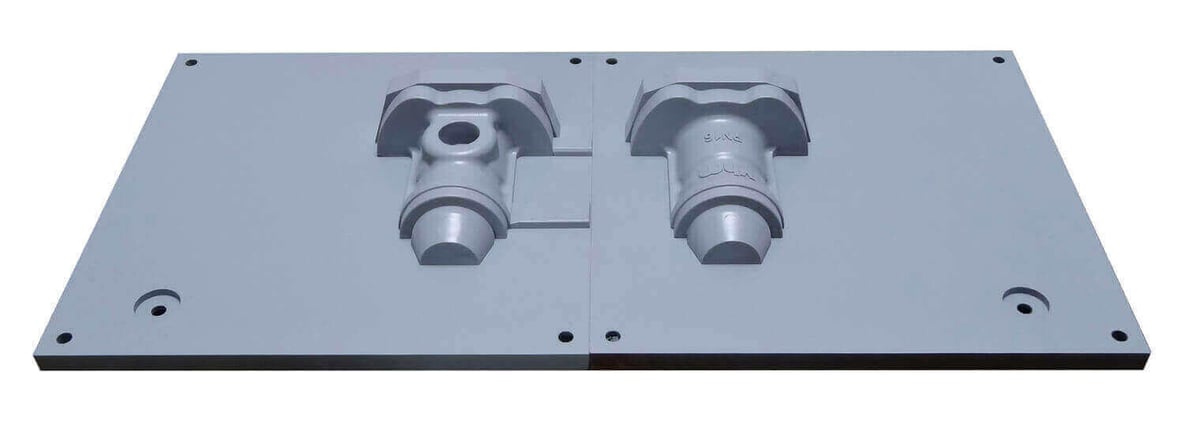

VHM Fonderie has been utilizing a Connex Multi-material 3D Printer to develop functional prototypes and master models that are used to produce manufacturing tools via sand casting. To produce these complex sand casting molds, the foundry has been 3D printing models with Rigur, Stratasys’ advanced simulated polypropylene material. After the master model of a specified part is 3D printed, a sand casting mold is created to manufacture the object in question.

3D Printing Models For Complex Sand Casting

By integrating PolyJet 3D printing into their workflow, VHM Fonderie has cut product development time from multiple weeks to a few hours, allowing for quicker order delivery to their customers. Additionally, the foundry has also used 3D printing to produce assembly jigs and spare parts for certain tooling machines. For instance, they recently increased production efficiency by 3D printing positioning jigs for use across their assembly line.

Believe it or not, Stratasys’ PolyJet 3D printing technology has become such an integral part of VHM Fonderie’s workflow that the company has established their own 3D printing bureau, Reali3D. The facility was created to optimize the production of 3D printed master molds, functional prototypes, and assembly jigs.

Laurent Poux, Industrial Director, VHM Group, said:

“We’re really excited to be able to extend the benefits of 3D printing to our customers through Reali3D, where we expect to produce everything from concept models and fully-functional prototypes, to assembly tools for the production line.”

All in all, VHM Fonderie’s use of Stratasys’ PolyJet 3D printing technology has led to faster product development and a more effective manufacturing workflow. This has allowed them to provide their Paris-based clients — which includes famous landmarks like the Le Jardin des Tuileries, Le Caroussel du Louvre, and La Place Vendôme — with the manufacturing tools they need in an extremely time-efficient manner.

License: The text of "French Foundry Produces Sand Casting Models with 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.