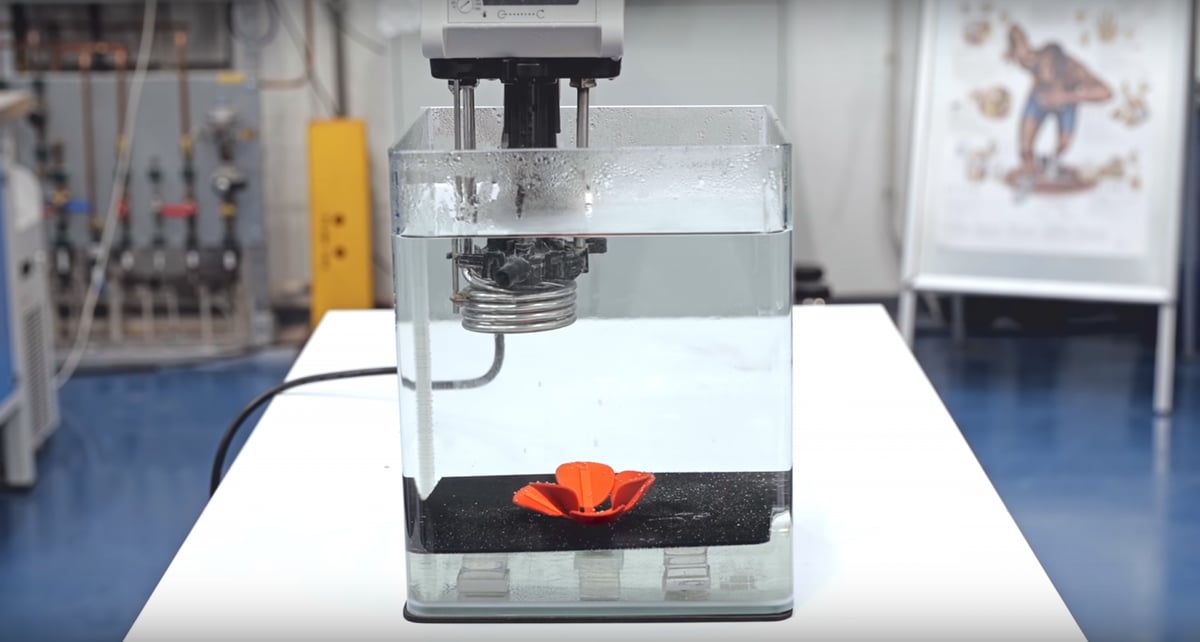

Researchers from TU Delft have developed self-folding origami-style 3D structures using sequential shape shifting mechanisms.

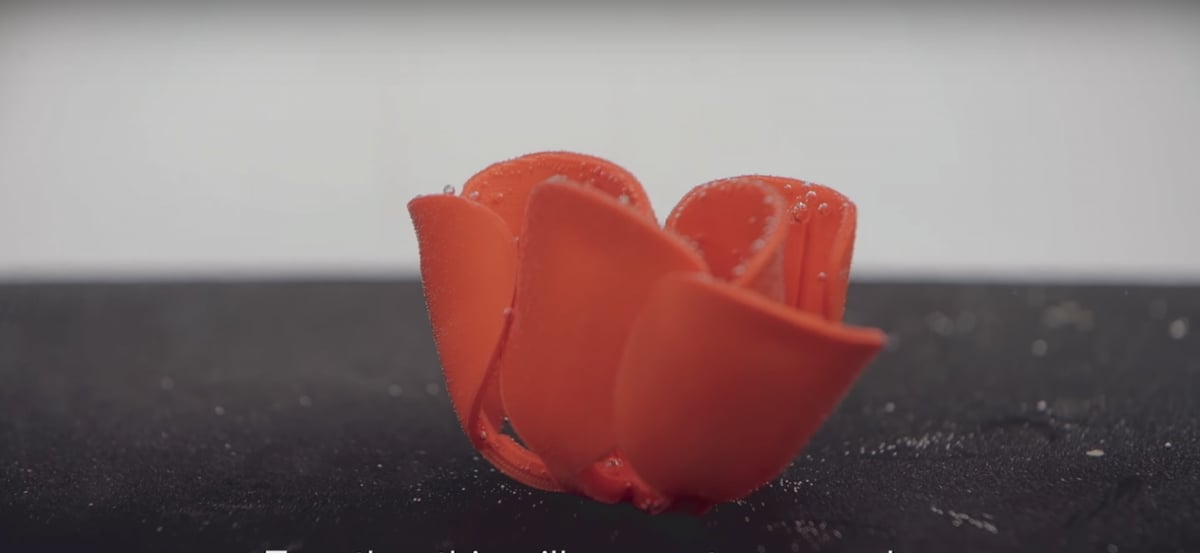

A research team at the Delft University of Technology (TU Delft) has created 3D printed flat structures which can fold themselves origami-style into shapes such as tulips. The self-folding mechanism is based on a pre-planned sequence, meaning some parts are designed to fold earlier than others.

If this type of research sounds familiar to you, well, that might be because MIT recently presented a 3D printed expanding polymer that can fold itself upon release from the print bed.

Unfortunately, the development of such materials is usually a costly affair. However, the TU Delft scientists say they only needed a desktop 3D printer and ubiquitous material for their structures.

Led by Amir Zadpoor, the team has previously designed self-rolling and twisting structures back in 2016. However, the original designs came with some serious challenges and lots of manual labour.

“At about 17 Euro’s per kilo, it’s dirt cheap. Nevertheless, we created some of the most complex shape-shifting ever reported with it,” says Zadpoor.

One of the key aspects of the new design is its pre-planned sequence. Complex shapes can be created if certain parts of an object fold ahead of others. The researchers utilised sequential shape-shifting to program time delays into their materials by printing and stretching the materials at the same time.

Teunis van Manen, a PhD student at the university, adds:

“When heated up, the memory is released and the material wants to go back to its original state.”

In addition, the thickness and outline of material filaments were alternated to create the 2D structures.

TU Delft Develops 3D Printed Self-Foldable Objects (But What Does That Mean?)

One important application for the team’s research could be the improvement of bone implants. By developing prosthetics with a porous interior, patient stem cells can attach to the inside of a structure as opposed to just the exterior to make for a more durable implant.

The origami-style, self-folding 3D printed materials also find application in nanopatterns to guide cell growth.

“We call these ‘instructive surfaces’, because they apply certain forces to the stem cells, prompting them to develop into the cells we want them to be”, explains Shahram Janbaz, a PhD at the TU Delft. “A pillar shape, for instance, may encourage stem cells to become bone cells.”

Although bone implants are the obvious choice to apply their research, the team hopes that the findings open the door to other developments. Zadpoor adds that printed electronics could potentially utilize the technique to incorporate 2D electronics into 3D shapes.

Another application could be self-folding furniture. Many of us despair at the thought of having to decipher the manual of an IKEA piece of furniture. Bring on the 2D IKEA sheets that fold themselves into a piece of furniture upon stimulation!

“Shape-shifting could definitely turn many of our existing 2D worlds into 3D worlds,” Zadpoor adds. “We are already being contacted by people who are interested in working with it.”

Source: TU Delft

License: The text of "TU Delft Melds 3D Printing and Origami to Produce Self-Folding 3D Structures" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.