Researchers from several institutions have developed shape-shifting 4D prints which can permanently transform when heated up.

For those folks dedicated to the art of 3D printing, a shape-shifting printed object is the stuff of their wildest dreams. That’s because when you print something currently, it’s final form is pretty much fixed.

Not anymore, however! Researchers from several institutions have developed a new 3D printing method to change this. Instead of remaining inanimate, printed objects can permanently transform into a range of different shapes. The simple trick is heat.

To make this possible, the researchers 3D print an shape using layers of shape memory polymers. Each of the layers then responds differently to a high temperature.

The team included researchers from Georgia Tech. Also, Singapore University of Technology and Design (SUTD) and Xi’an Jiaotong University in China.

Jerry Qi is a professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech. He explains:

“This new approach significantly simplifies and increases the potential of 4D printing by incorporating the mechanical programming post-processing step directly into the 3D printing process.” He adds: “This allows high-resolution 3D printed components to be designed by computer simulation, 3D printed, and then directly and rapidly transformed into new permanent configurations by simply heating.”

Eventually, as well as heat, parts could also respond to moisture, light and temperature. The researchers also hope that the technology could be precisely timed to create anything from robots to deployable medical devices.

What Do Shape-Shifting 4D Objects Mean for Product Design?

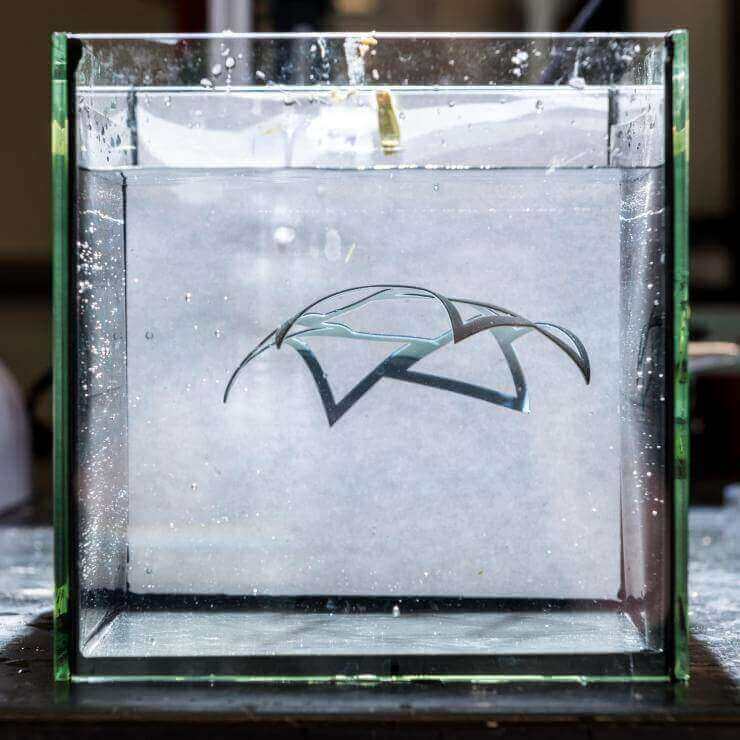

To further show how this process works, the team developed a few objects which could change shape in hot water. They chose a model of a flower with bending petals and an expanding lattice shape.

Zhen Ding, a postdoc researcher at Singapore University of Technology and Design, said:

“Our composite materials at room temperature have one material that is soft but can be programmed to contain internal stress, while the other material is stiff. We use computational simulations to design composite components where the stiff material has a shape and size that prevents the release of the programmed internal stress from the soft material after 3-D printing. Upon heating the stiff material softens and allows the soft material to release its stress and this results in a change – often dramatic – in the product shape.”

One main advantage of this technology is that the 4D objects could enable a range of new features. The new shape-shifting method could change product design as we know it. For example, rolling or stacking products for shipping suddenly becomes a lot easier.

Martin L. Dunn is a professor at Singapore University of Technology and Design. He is also the director of the SUTD Digital Manufacturing and Design Centre. He said:

“The key advance of this work is a 4D printing method that is dramatically simplified and allows the creation of high-resolution complex 3D reprogrammable products.”

Want to find out more? Head over to the Science Advances journal where the research was recently published.

Source: Georgia Tech

License: The text of "These Shape-Shifting 4D Objects Transform with Heat" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.