With the launch of the HP Jet Fusion 3D Printer, the CEO of Shapeways explains how their partnership with HP continues to flourish.

Related: HP Launches Jet Fusion 3D Printers at Rapid 2016

Shapeways is a leading provider of online professional 3D printing services. So it makes sense they would welcome the arrival of a new commercial 3D printing technology. Anything that prints faster, better and cheaper is good for business, and there’s a waterfall effect for anyone who uses or makes 3D printed products.

What we learned on a recent visit to the HP 3D printing lab in Barcelona, however, was how extensive the collaboration between Shapeways and HP had been, and more about the motivation behind it. Shapeways CEO Peter Weijmarshausen gave assembled analysts and journalists a presentation to this effect, which we recount here.

The relationship between Shapeways and HP began all the way back in 2014, when rumors were circulating that HP might be interested in 3D printing. “Some of you may know Shapeways was founded over nine years ago,” says Weijmarshausen.

“I was always looking for new and interesting things that were happening. After a little bit, I got a phone call from Stephen (Nigro, President of 3D Printing at HP), and he said basically to me we’ve been researching 3D printing, and what we found is that currently the machines are way too slow. They’re way too expensive. The quality isn’t matching the customer needs, and the machines are not ready for manufacturing. What do you think of those statements?”

Weijmarshausen was in complete agreement, citing community feedback that had outlined the exact same problem. And that’s were their conversations began in earnest; the Shapeways CEO was given a sneak preview of the technology HP was developing, to which his reaction was “I was really, really happy” and “we are, I believe, on the eve of a new industrial revolution”.

Shapeways CEO: “You Should Read The Cluetrain Manifesto”

Shapeways currently has factories in New York City in the United States, and Eindhoven, in the Netherlands, and both are reportedly profitable operations despite being expensive places to manufacture. “As Frank Sinatra sang, ‘if you can make it here, you can make it anywhere’. I took that lesson to heart; tried it, see if it works, how we can extend this.”

It’s always fun to get a book recommendation, even more so when it’s from a major figure in the 3D printing industry. “An eye opener for me was really The Cluetrain Manifesto,” says Weijmarshausen. “If you haven’t read it, I highly recommend it because it talks about why our whole society is built around mass manufacturing. What will happen to society when we start to depart mass manufacturing, and move into the new age of digital manufacturing?”

Indeed, that’s exactly what’s happening now, with the transition to the personalized creation of books, greetings cards, photo albums, even Coca-Cola cans. Or the on-demand publishing of books. Or the digital marketplaces for apps, games, music and movies. “We are just scratching the surface. So much more is going to come,” he enthuses. “And as a result of that, the role of the companies will completely change. What will be made will change.”

A prominent example was the Super Bowl in 2015, where Katy Perry’s half-time concert went hilariously awry when a backing dancer in a “left shark” costume forget their routine. The very next day, figurines depicting Left Shark were uploaded to Shapeways and went on sale. And just as swiftly, lawyers representing Perry demanded they be taken down. This is disruptive technology at work, rapidly going from idea to market, and a great leap beyond anything possible in mass manufacturing.

What’s Driving the Next Industrial Revolution?

One theory about what’s driving the new industrial revolution is the number of “megacities” around the world. “We had ten in the 1990s. We will have over 40 pretty soon. And five billion of the eight billion people on this earth will be living in the cities.” That, Weijmarshausen argues, is creating huge supply-chain issues. One solution to that is localized manufacturing.

The second driver is globalization. The emergence of a global marketplace moves the focus away from Europe and the United States to literally everywhere. Which means localized production taking into account local cultures will be more important to succeed in a global market. This runs contrary to mass manufacturing, where businesses try to sell an identical product over and over (and over) again.

Finally, there’s technological disruption. “The computer is getting more and more powerful. And that won’t stop. And as a result of it, more and more of our content will be digitally created.”

So what has Shapeways learned over the past nine years? They saw the rise of the home printer, for starters, but Weijmarshausen takes issue with a desktop machine being categorized as consumer 3D printing. Rather, his company is the genuine article:

“We take paper as an example. You can see that 95 percent of paper is printed in services and 5 percent at home. Most people have a paper printer at home, but where do we print our photos, where do we print our birthday cards, where do we print our Christmas cards or photo albums, etc. etc.? We print them in a service bureau.”

Weijmarshausen also cites limited innovation on the industrial side of 3D printing. “We are actually using six-year-old machines currently in our factories, because they are ‘old’ state of the art. And that was actually my biggest surprise being a novice in the 3D printing market nine years ago – not as much anymore – but I was hoping for much more innovation, and it didn’t come.”

Another learning is about speed and cost. Customers today are accustomed to next-day — sometimes same-day — delivery with services like Amazon Prime. Shapeways is striving to match that same speed. ”With this technology (Multi Jet Fusion), we can,” he says.

In terms of cost, the story is about prices falling, but they’re not falling quickly enough: “When we started, my iPhone case was $250.00. Currently, you can buy it on our site for $20.00. But that’s for small items, so the bigger it gets, it gets very much more expensive in a hurry.”

Shapeways CEO: “This Market Needs a Catalyst”

These are only a few indicators of why the Shapeways CEO is excited about the HP Jet Fusion 3D Printers. “This market needs a catalyst. And I think (Multi Jet Fusion) might be the catalyst, together with a few killer apps. Giving access to many, many people to this technology will catalyze this market into what it truly can become.”

Weijmarshausen is convinced that HP is truly embracing 3D printing, and they’re going about it the right way:

“It’s (been a process of) closely working together, being open to making mistakes, exposing one another to our failures and our successes. And I think in working with HP I’ve discovered it’s been really nice because we share the same values. We wanna make the end customer happy, and we do that in working together in a very collaborative way. So I’m very happy.”

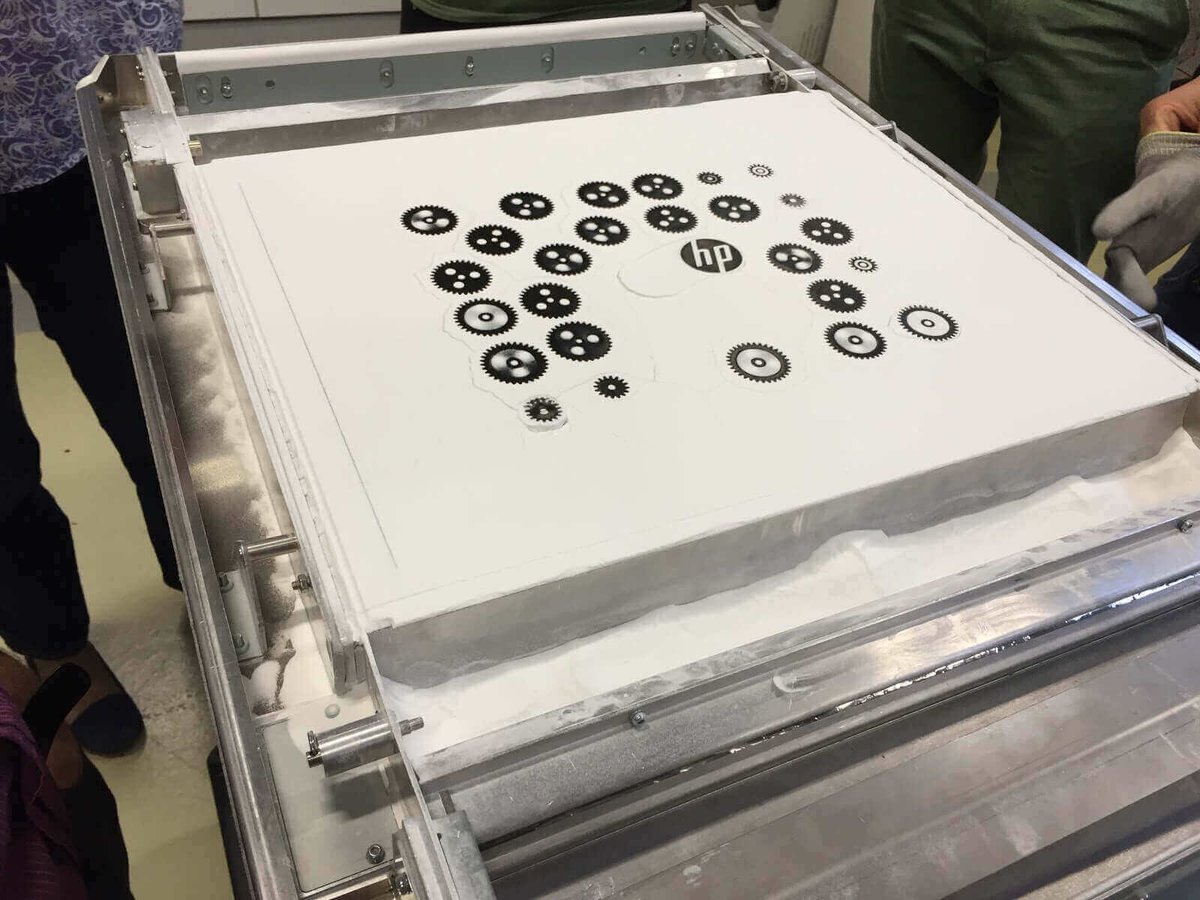

Shapeways has now taken delivery of a prototype HP Jet Fusion 3D Printer in their Eindhoven factory, and there’ll be a constant stream of information and feedback between HP and Shapeways. Pictured in the main image above are Virginia Palacio from HP with Stefan Rink, Shapeways VP of Manufacturing.

They’re still in the early stages of testing, but Weijmarshausen has promised to keep his customers posted on their progress and — most exciting of all — hopes to begin using the machine to print parts very shortly.

License: The text of "Shapeways is Excited about HP Jet Fusion 3D Printers" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.