3D printing is still a field where technical innovation is happening on a daily basis. Just when you think a 3D printing technique is sufficiently explored, innovation sparks. Currently, new and improved SLA 3D printing technologies are announced almost on a weekly base, and one outperforms the other with its estimated specifications. In Part 1 of this article series, I’ll explain what SLA 3D printing is and how it has gained momentum recently.

SLA 3D printing works by hardening liquid resins with light rays. These can be, for example, focussed light, UV, or lasers. Most SLA printers create the prints from top to bottom, as the build platform moves the object upwards, lifting it out of the resin bath.

In February, Autodesk, the company that initially only did CAD software, started accepting orders for its SLA 3D printer “Ember” by the general public. It’s the company’s first foray into hardware . It was a showcase not only for their 3D printer software platform, but a big step forward for SLA 3D printing. Such big players as software giant Autodesk putting their money on SLA 3D printing was a clear evidence of the potential of SLA technology.

But SLA 3d printing wasn’t so evidently powerful at that time. Being a 3D printing technology delivering very accurate prints with high precision, it wasn’t very fast in turn.

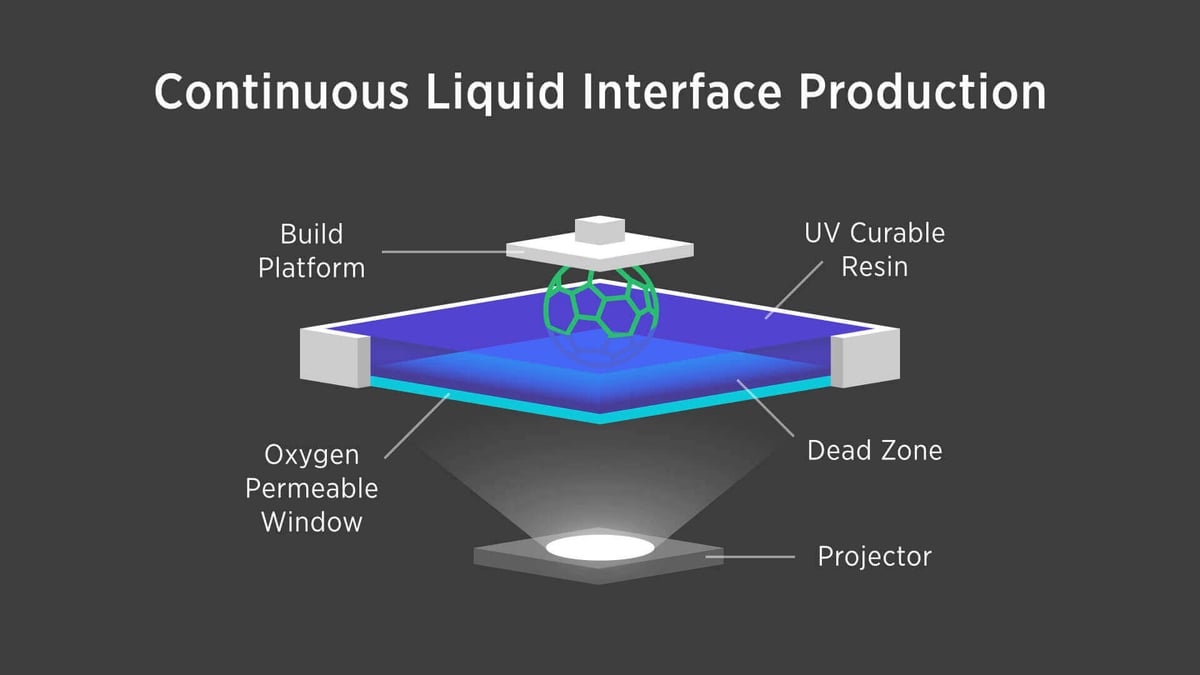

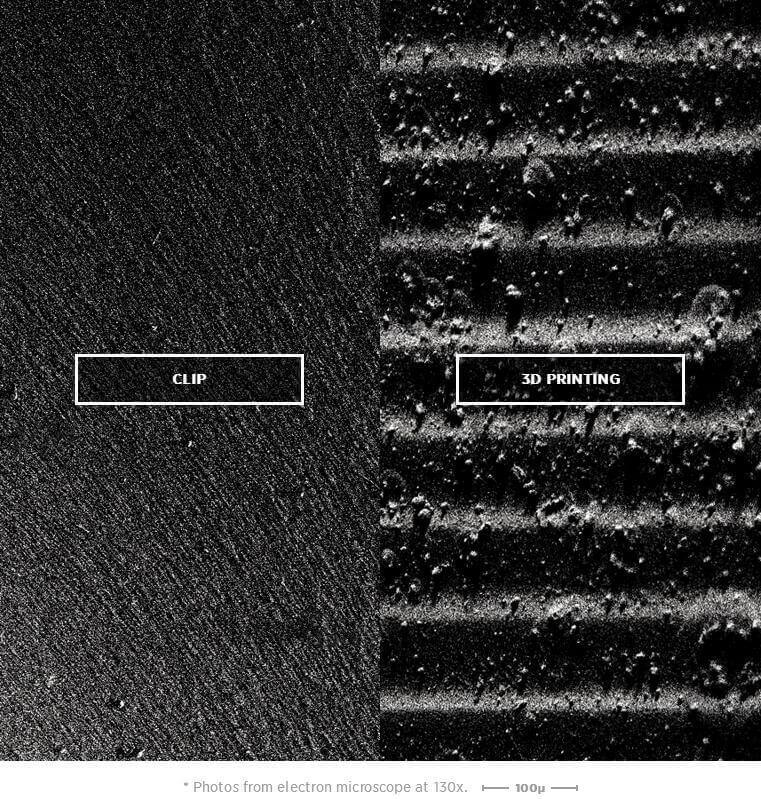

Then, this March, Carbon3D, which was unheard of before, suddenly announced a technology called CLIP, which according to their claims prints up to 100 times faster than any other 3D printer available. Carbon3’s CLIP technology uses light and oxygen to cure a photosensitive resin and inhibit the curing. Objects printed using the CLIP technology have a smooth surface, with no print layers or dusty surface that most of the other printing techniques leave behind.

“By working at the intersection of hardware, software and molecular science, we are aiming to fundamentally address the issues that have held 3D printing back from becoming a manufacturing process”, said Dr. Joseph DeSimone, CEO and co-founder, Carbon3D.

Not long after the CLIP technology was presented, the Australian company Gizmo3D arrived on the scene. Their technique, while similar to existing ones, promises an even higher speed. Kobus du Toit, founder of Gizmo 3D Printers, explained that instead of printing layer by layer, each layer receives a flash from the projector that “draws” the projected image to harden in the resin. This means that this method prints more like an continuos animation that is projected. The build plate moves downward continuosly in the fresh, uncured resin. Du Toit calls this method “continuous printing” but “animated printing” might even be a better term. As long as he has not fully patented the necessary steps, du Toit won’t explain how exactly his invention works to not encourage copycats. He wants to start a crowdfunding campaign for his method as soon as he has finished beta testing and refined the process.

“I don’t want to do what the other companies are doing and release an unfinished product because I know how it feels. When my beta testers are happy I can release”, explains Kobus du Toit of Gizmo 3D Printers.

Furthermore, the big headlines SLA 3D printing made brought another company to the scene. This time, an Asian company called Prismlab. They unveiled a whole line of super-fast SLA 3D printers that are officially capable of printing 8-10 times faster than their competitive solutions. Based on Chinese media reports, these numbers could be an understatement though. They calculated a whopping 2,712cm³ of material that was cured in a single hour while curing over 3kg of material. Miscalculation or unconfirmed top performance? Judging from the existing videos, it could be true.

In Part 2 of this article series, we will explore, if you can build a SLA 3D printer at home and how easy and affordable the technology really can be.

License: The text of "SLA 3D printing is in an arms race" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.