A world leader in supplying fake snow, Snow Business use Ultimaker 3D printers to save cost and time in prototyping and testing final parts.

Don’t Miss:

Have you ever wondered who supplies the snow for movies which weren’t filmed during winter months? For example, titles like Spectre, Kingsmen, or Bridget Jones’s Diary?

The answer is Snow Business. The company supplies fairs, productions and live events with snow machines which help set the perfect ambience. What Christmas fair would be complete without some festive fake snow?

However, making a snow machine’s complicated final design requires a lot of iteration. To make things better, the company is using an Ultimaker 3D printer.

By doing this, they can prototype, test and even create final parts for the machines. A major benefit of the technology, of course, is that the company can speed up their iterative design process and save money by having a 3D printer in-house.

The company began by outsourcing parts; however, they found this took too much time. Paul Denney, Head of Research at Snow Business, explains:

“What I really needed was a technology that I could use myself, on-site, that would be able to do what I needed it to do. That’s when we bought our first Ultimaker.”

That’s Snow Business: 3D Printing the Perfect Fake Snow Nozzle

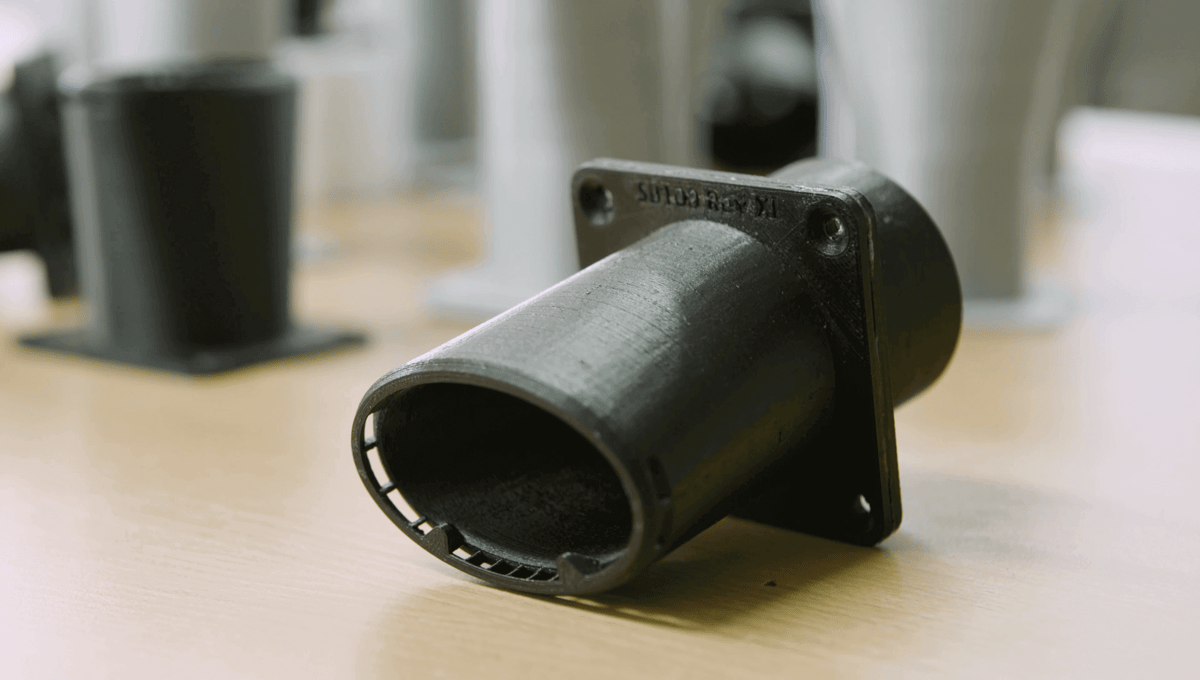

Thanks to 3D printing, creating the machine’s nozzle is a much simpler process than before. If you’re wondering, the nozzle is where air mixes with fluid to create a beautiful snowfall effect.

However, the reason they’re so difficult to manufacture is that their shape is extremely complex. In fact, the air and fluid flow geometry makes the part impossible to cast by conventional injection moulding. 3D printing is undeniably the better option but even so, the process requires extensive trial and error.

Additive manufacturing saves the company a lot of money in the long term, even with extensive iterations. Denney estimates the first printer paid for itself within just two weeks of purchase.

The company prints the nozzles in ABS on the Ultimaker 2+. Using this method, Denney would split the model up into two parts. After printing he’d glue them together. By doing this, he would avoid support structure marks on the ABS print.

However, the company is now investing in a second 3D printer — the Ultimaker 3. The benefits of buying this printer are already clear. Denney can save both time and money by printing the nozzles in one piece.

To do this, he now uses Nylon and water-soluble PVA support. As a result, the final prints don’t require any post-printing assembly and have no marks.

Want to find out more about Snow Business? Head over to their website, or check out Ultimaker to see their latest range of 3D printers.

Source: Ultimaker

License: The text of "Snow Business: 3D Printing Fake Snow Nozzles using Ultimaker" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.