Somos and 3D Hubs are joining forces to offer customers access to highly accurate 3D printed tools and molds with a quick turnaround time.

The Dutch company 3D Hubs has made a name for itself by offering customers localized and professional 3D printing services. This has allowed people without 3D printers to have their ideas produced no matter where they are.

Now, 3D Hubs is partnering up with the 3D printing materials producer Somos to focus in on a more industrial market. The aim of this collaboration is to offer accurate 3D printed tools and molds with fast turnaround times.

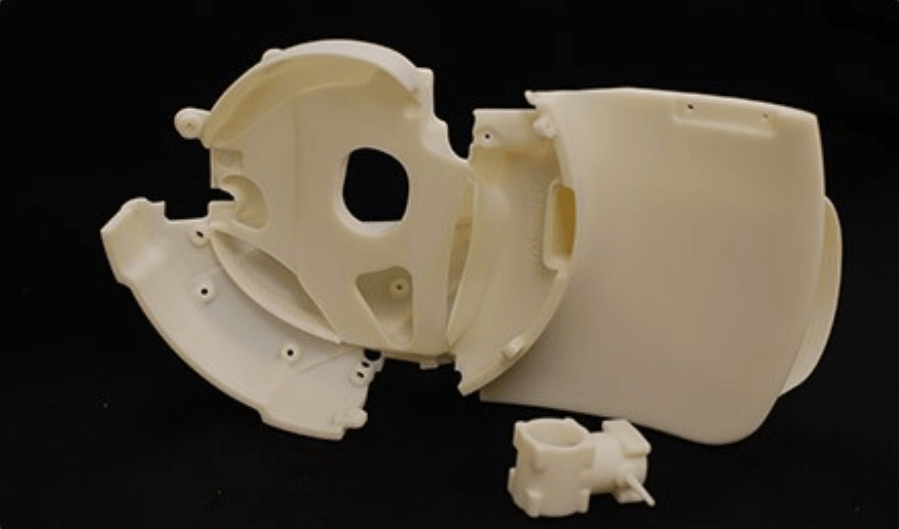

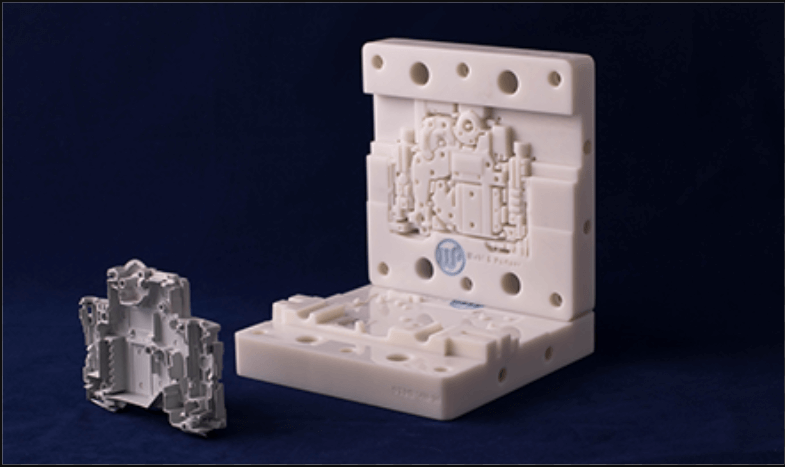

Somos is bringing their PerFORM material to the table, while 3D Hubs, of course, offers their global service and network. PerFORM is ideal for tools and molds because it can produce composite parts with strong, stiff, and high temperature resistant properties.

Somos and 3D Hubs Efficiently Create Tools and Molds

With 3D printing, it’s possible to have a perfectly customized tool in your hand faster than with traditional methods. 3D printed tools are also typically cheaper than machined tools.

Brigitte Jacobs, Application Development Manager for Somos, said:

“We are excited to collaborate with 3D Hubs to offer the market a place where they can obtain high quality 3D printed tools and service. We work closely with 3D Hubs to verify the 3D printing tooling service providers in their network to ensure that the quality and expertise for creating the tooling is top notch.”

The tools 3D printed using PerFORM material can be ready for use in just a few days. This is a much shorter timeframe than other manufacturing techniques can muster up. Usually, tools and molds can take a number of weeks to be ready with traditional methods.

By using 3D printing, customers will be able to test their product designs and modifications quickly. This way, the whole process speeds up, helping to also reduce production costs and bring products to the market.

Bram de Zwart, the CEO of 3D Hubs, explains the benefits of adding PerFORM to their material portfolio:

“The collaboration with Somos on 3D printed tooling further expands our network of manufacturing services and product offering… We are always targeting to offer our customers cutting edge materials and service. Adding Somos PerFORM to our portfolio expands what our customers can do and allows them to create high quality 3D printed tools.”

The primary reason for this powerhouse pairing with Somos is the noticeable increase in people using 3D printing to produce tooling and molds. From engineers to technicians, many are finding this emerging technology to be a suitable manufacturing method for their needs. As 3D Hubs aims to make 3D printed tools and molds more accessible to all, that trend is likely to continue.

Source: DSM

License: The text of "Somos and 3D Hubs Collaborate to Create 3D Printed Tools and Molds" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.