Researchers from Texas Tech University are developing a novel way to strengthen 3D prints using microwaves and carbon nanotubes.

The main mechanical problem with FFF prints is well known. Weak layer bonding at the layer boundaries is inevitable, and can be the cause of breakages in 3D prints. For manufacturing industries, these breakages pose a major problem.

Researchers from Texas Tech University see this as the “chief obstacle to the use of thermoplastic additive manufacturing.” However, they are hot on the heels of a solution, with a patent pending method to strengthen 3D printed parts.

Most notably, their method involves the application of microwaves after printing. They explain: “We report a novel concept for welding 3D printed thermoplastic interfaces using intense localized heating of carbon nanotubes (CNTs) by microwave irradiation.”

Thanks to this process, they can increase the weld fracture strength by an impressive 275 percent.

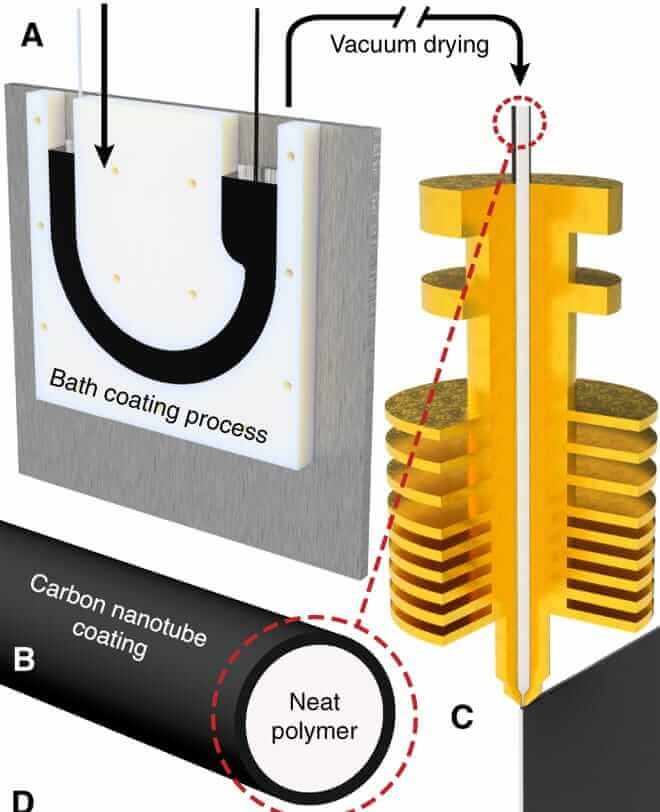

A major benefit of the research is that it doesn’t require any fundamental changes to FFF 3D printing. But, one major workflow alteration is necessary — namely the addition of a microwave post-processing chamber.

Using Microwaves and Carbon Nanotubes for Stronger 3D Prints

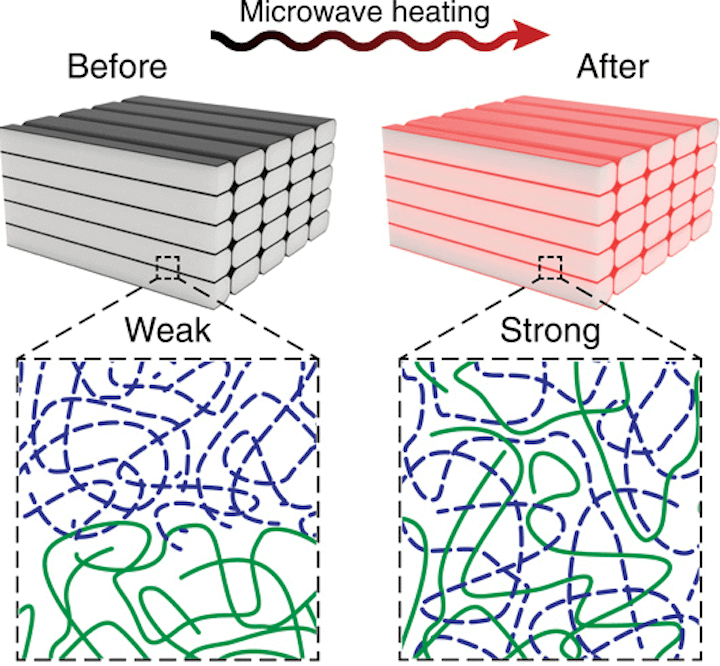

Limited contact between the material at its layer boundaries is the typical cause of weakness in FFF 3D prints. But the secret to the researchers’ success lies in their special treatment of filament.

To begin with, they coat stock spools of PLA filament with carbon nanotubes. During printing, these usually remain on the outside of the prints, and therefore become form adjacent layers throughout prints. After this, the researchers use a post-print microwave application. They explain:

“Upon exposure to microwave irradiation, these MWCNT-loaded interfaces selectively heat, which promotes increased local polymer mobility and entanglement across the interface.”

Ultimately, layer adhesion is increases after just one minute of microwaving to introduce temperatures of 160 degrees Celsius. However, the researchers also add that this system “relies on the precise composition and microwave responsiveness of the coating.”

But, it’s certainly an interesting start with promising results so far. For further reading, head over to Science Advances, where the findings were published.

Source: Fabbaloo

License: The text of "Texas Tech Researchers Strengthen 3D Printed Parts with Microwaves" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.