New company Carbon promises to take professional 3D printing to a new level with new materials and a significant speed boost. All3DP’s columnist Rachel Park takes a deeper look.

The significant growth rate of the 3D printing industry in recent years continues to attract an increasing number of companies both large and small to the space. As the multi-national conglomerates — the likes of HP, Canon, Ricoh, Polaroid, and Toshiba — ramp up R&D, marketing strategies and production around varied 3D printing solutions, new start-up companies can face an uphill battle to get their voice heard amid the cacophony. There is no fail-safe formula for success but it certainly contains a metered combination of an original idea, adequate funding, experience, good execution, networking, entrepreneurial spirit, building a cohesive team and, of course, just a little bit of luck!

Breaking Barriers With News Materials and Improved 3D Printing Speed

There is one relatively new company that seems to be getting that formula right, namely Carbon, or as the company was originally named when it launched 18 months ago, Carbon3D. The company made a huge impression with a TED talk, which you can see at the end of the article. The experience of the founders in developing the CLIP 3D printing process, plus some serious financial backing (more than $140 million with more on the way by all accounts) plus faultless execution to date, supported by some strong personalities and clever networking have all ensured that this start-up company garnered phenomenal attention ahead of commercial launch earlier this year and have generated a powerful client list through beta-testing since.

Let’s take a closer look at what Carbon has actually done:

The foundation is undoubtedly the development of a new photopolymer process – the Continuous Liquid Interface Production (CLIP) process — which utilizes both UV light and oxygen to precisely control photopolymerization continuously. Science aside, what this means is that the CLIP process is 25-100 times faster than other photopolymer processes, and, uniquely to Carbon, the process works with a much broader range of production grade materials, including thermoplastics and elastomers.

Carbin CLIP Materials are the Key

And this is the key, I believe, to Carbon’s vision for 3D printing — the materials!

Since the inception of additive processes 30 years ago, materials have been cited as one of the greatest limitations of the technology and despite many advances over the years, materials are still a major barrier to adoption for many applications. I believe Carbon’s vision is to remove this barrier — due in no small part to the extensive expertise of the company’s CEO & Founder, Joseph DiSimone, a materials scientist. Sculpteo and Carbon are looking at materials like Rigid Polyurethane (RPU), Elastomeric Polyurethane (EPU), Flexible Polyurethane (FPU), Prototypic Acrylate Resin (PR) and Cyanate Ester (CE). Partnerships are part of the plan too, as evidenced by Carbon signing a joint development agreement with Kodak — a large global company with vast expertise in chemistry and materials development.

Carbon has not over-promised or moved too fast, rather it steadily and carefully built up to the commercial release of its first product offering — the M1 3D printer earlier this year, while quantifiably demonstrating its results via beta testers pre- and post-launch.

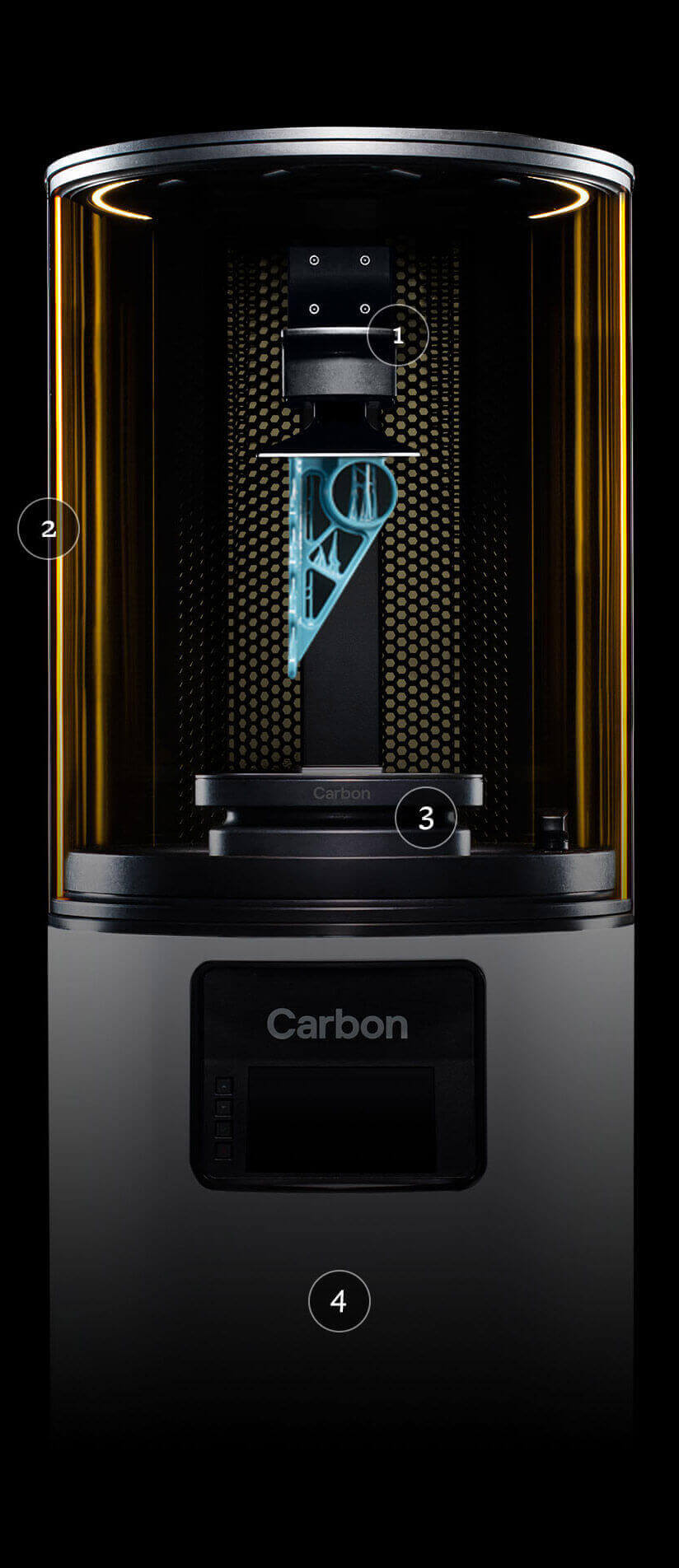

First in the CARBON Series: The M1

The M1 itself demonstrates some interesting specifications at launch, but be in no doubt this is a first gen machine. Right now it boasts a build volume of 144 x 81 x 330 mm; a light engine projecting 75 micron pixels and thus an XY resolution of 0.075 mm; an onboard GPU processor to speed up motion calculations and push the print durations down as low as possible; and internet connection via cloud-based servers, allowing remote operation. The parts produced are extremely accurate, however, the nature of the process can demand long post-build cure times.

One of the first companies to be revealed as a beta tester and reporting positive results was the Ford Motor Company last year, ahead of the M1 being formally launched. This was followed by Carbon announcing an extension of its early customer program, which included CIDEAS, Sculpteo, Technology House and WestStar Precision. The angle here was shown to be that by partnering with these leading service bureaux and contract manufacturing customers, access to Carbon’s technology platform — and materials palette — was greatly increased without full roll-out.

More recently, Carbon revealed Delphi and BMW as early adopters of the M1 platform, which is revealing in terms of where Carbon sees its key target markets. Delphi demonstrated how it is developing functional prototypes and running true part validation testing as well as exploring new opportunities for the production of final, end-use additively manufactured parts for the first time.

Operationally, Carbon has continued to grow steadily with personnel at its California facilities now numbering more than 130. This is backed up by some strategic (and shrewd) board appointments, most notably that of Ellen Kullman — the former Chair and CEO of DuPont. In this case, Ellen’s credentials speak for themselves and add gravitas to the direction and vision of Carbon. The company’s growth and strategy has not gone unnoticed either — as testified by Carbon’s appearance on MIT’s most recent “Top 50 Smartest Companies” list.

If You Want a CLIP 3D Printer, You’ll Have To Subscribe

In terms of actual figures the basic subscription price for a single M1 platform is US$ 40k per year, for a minimum of three years. There is also an initial installation and training fee of US$ 10k as well as US$ 12k for the required accessories pack and the Cyanate Ester starter pack. The materials are then supplied separately, which range from US$ 99 to US$ 399 per 800 ml.

This pricing model definitely needs perspective — for most desktop 3D printer users the eyes will likely continue to water, but these 3D printer users are not the target market. This is an industrial additive manufacturing machine, not just a “rapid prototyper”, and for large OEMs the proposition is an alternative to conventional methodology for directly producing higher performing parts with greater functionality. As such the price : performance ratio could prove extremely appealing.

Personally I have no doubt that Carbon’s approach will have a significant impact on the 3D printing industry landscape. Other commentators have similarly cited it as being a “game changer.” For anyone familiar with 3D printing news, and particularly the headlines, this type of rhetoric is not uncommon — but either way, this company is definitely one to watch!

License: The text of "The Carbon Factor: Next Level in Professional 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.