MIT’s Computer Science and Artificial Intelligence Laboratory has constructed the MultiFab printer. It is capable of printing ten different materials in one session, and embedding other components.

Different types of materials are being printed every day. In fact, another MIT group shared their discoveries on how to 3D print glass. Unfortunately, most printers are restricted to only one type of material at a time. While multi-material printers have come into existence, they are often very limited, carry a huge price tag, and require a good amount of human interaction.

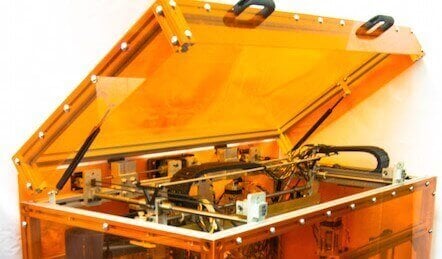

CSAIL’s new printer, the “MultiFab,” is set to be cheaper, more efficient and, quite simply, record breaking. The printer was built at MIT from low-cost off-the-shelf components that cost a total of $7,000.

A Possible Game-Changer for 3D Printing

MultiFab’s ability to embed circuits, sensors and other complex components into designs means, theoretically, this printer will do all of the work for you.The resolution can get to 0.04 millimeters. From nearly flawless design to all-in-one printing, every step of this printer’s processes could be game-changing for the world of manufacturing.

CSAIL claim that „MultiFab can print everything from smartphone cases to LED lenses, with an array of applications in consumer electronics, microsensing, medical imaging, and telecommunications.“ They plan to also experiment with embedding motors and actuators. That would make it possible to 3D-print more advanced electronics, including potentially even robots.

3D Print Robots in just One Session

Still, 3D printing is very alien for ordinary people, and the highly practical MultiFab may help bring new faces into the field. With the ability to print fully assembled pieces from numerous materials, just about anyone can find real use in 3D printing.

Of course, this also means the world of medicine and tech are coming ever closer to a major shift. As CSAIL tinkers with embedding motors, they’ll aim to 3D print advanced electronics, and perhaps even a complete robot. MultiFab’s contributions to printing will be far-reaching, and the folks behind it are excited to see results.

CSAIL research engineer Javier Ramos shared some simple but powerful words: “Picture someone who sells electric wine-openers, but doesn’t have $7,000 to buy a printer like this. In the future, they could walk into a FedEx with a design and print out batches of their finished product at a reasonable price… For me, a practical use like that would be the ultimate dream.”

License: The text of "The MultiFab: 3D Print Multi-materials, No Assembly Required" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.