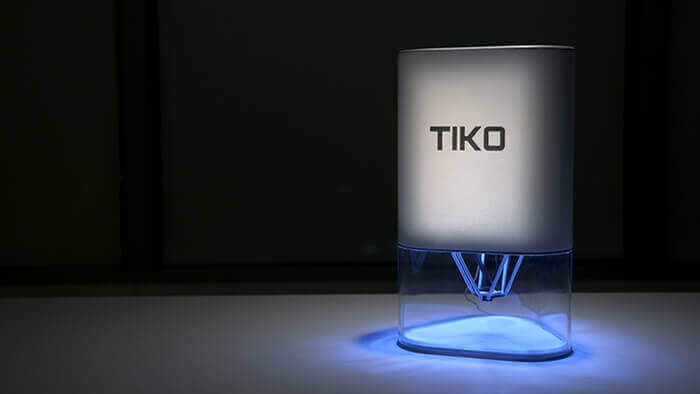

Tiko is a compact unibody 3D printer that has already blown the Kickstarter community away with its promise to deliver perfect first-time prints at the cost of $179! The crowd-funding campaign has already received ten times its initial goal of $100.000, and it still has 22 days to go! But can Tiko manage to deliver such a stunning product in such a low price range?

Tiko developers were trying for years to develop a 3D printer that would combine all the positive characteristics found in expensive models and implement them into a robust low-cost machine. This was especially challenging as there was nothing that they could use from the available parts in the market. So they decided to create something completely custom and develop each and every part towards a new design. The result is a printer that has nothing in common with most other low or medium cost 3D printers, other than the fact that it can use any 1.75mm filament in the market.

Easy Makes It

Since the frame is what generally makes other models so complex, heavy and expensive, Tiko designers decided that the best option would be a unibody (one solid part) frame, eliminating all the misalignment issues that derive from the de-calibration of rails. This theoretically means that Tiko doesn’t require constant calibration, and also that it is extremely light (1.7 kilograms) and easy to manufacture.

Inside the frame lies the filament spool that can be up to 1 kg while the bottom part is dedicated to the printing area, which is completely enclosed. The shape of the frame is a rounded triangular cylinder measuring 390 mm in height, 237 mm in width and 221 mm deep. Its printing chamber occupies about 32% of it, boasting a printing volume of 2.27 liters.

As you probably already suspected from the frame’s shape, Tiko isn’t using the standard approach of the cartesian arms, but a delta mechanism with parallel arms that are fitted to the internal rail of the frame. Delta architectures, combined with consumer-level tolerances, can deliver results that directly compare to those of very high-precision machines that are significantly more expensive. Other custom designed parts include a nozzle that is made from aerospace-grade Titanium alloy and features very low heat flow, and thus very high energy efficiency.

Perfection Is of This World

The liquefier is an implementation of a smart design that is passively cooled by moving air through precisely designed vents. This allowed the geometrically simple assembly to be free of fins and low on part count, so way cheaper to build than anything else of this kind. The electronic parts of Tiko were also developed from scratch to meet the low-cost and high-precision criteria of the team. The low energy consumption of the printer also lowered the required specifications for the electronics, allowing simpler and cheaper components, as well as a much smaller, lighter and cheaper power unit.

Tiko is safe and easy to use as it auto-shutdowns when it’s tilted, auto-stops printing when the filament is about to run out, and it can even auto-calibrate its components using a smart accelerometer. Its design software is accessible from anywhere online as a browser app, it can print using WiFi and it features a bendable yet strong print bed that you twist slightly for easier model removal. Tiko might just be the perfect 3D printer to set off the next wave of mass consumer adoption.

Are you ready of it? Help then kickstart it. All3DP will continue to report on the Tiko.

License: The text of "Tiko kickstarts the future of 3D printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.