Hinckley uses lightweight composite structural components and titanium 3D printing to build all-electric 28-foot Dasher yacht.

For almost 90 years, the American yacht manufacturer Hinckley has been making waves of innovation from the coastline of Maine. The company is known for fusing cutting-edge technology with classic naval styles, so it was only a matter of time before 3D printing was integrated onto their production line.

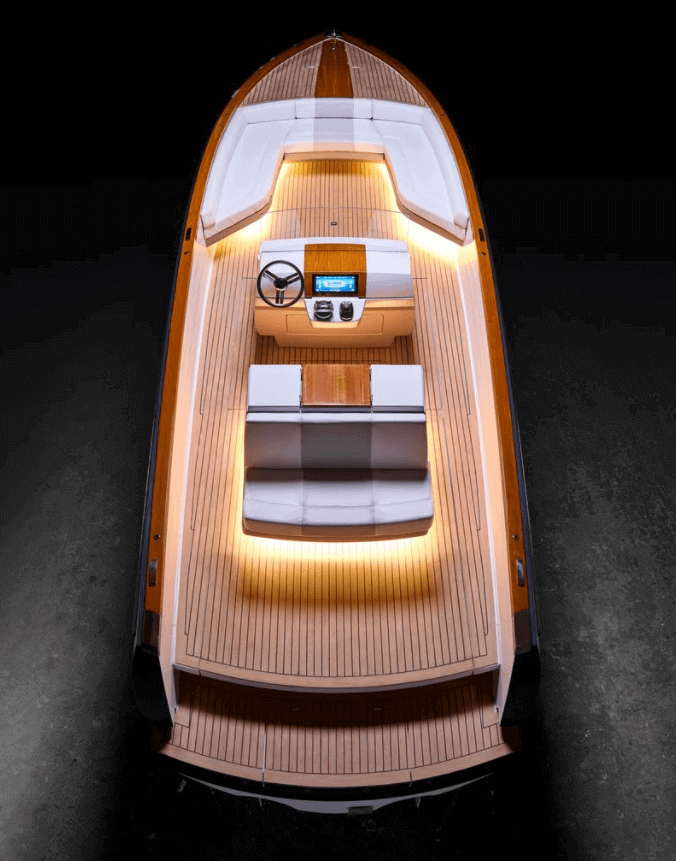

The 28.5-foot Dasher is Hinckley’s first-ever all-electric yacht. It features composite structural components and metal 3D printed components. The name of the luxury boat is inspired by the vessel style debuted by the company in 1994. However, this time around, Hinckley is using electric propulsion, carbon fiber, and additive manufacturing to create a more lightweight and environmentally friendly boat than ever before.

Hinckley Dasher: Innovative Technology Leads to Evolution of Classic Yacht Style

Like all other Hinckley yachts, the Dasher is manufactured using the Seeman Composite Resin Infusion Molding Process (SCRIMP). But, this all-electric sea vessel also contains 3D printed titanium hardware components. With additive manufacturing and carbon fiber, the company is able to reduce the overall weight of the boat. In fact, at 6,500 pounds, the Dasher is lightest boat that Hinckley has ever built.

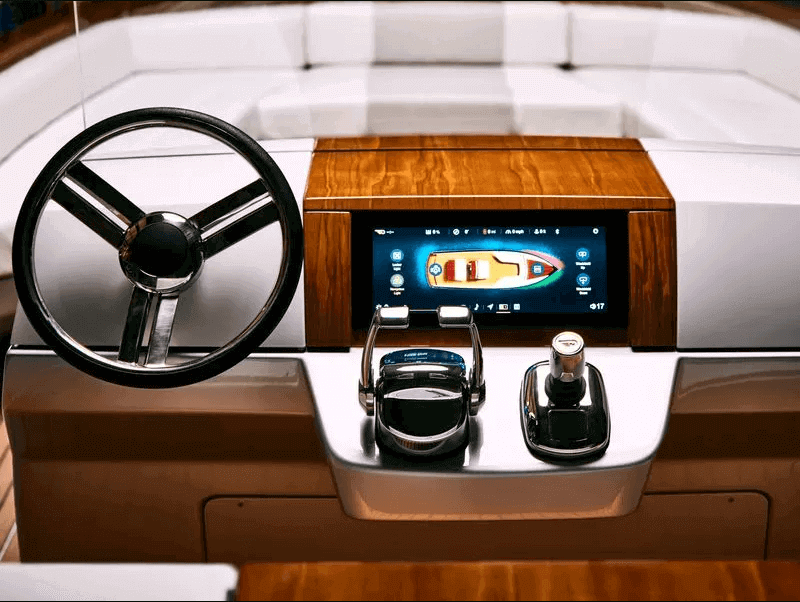

Their use of 3D printing also contributes to reduced production times and the ability to manufacture parts with complex geometries. The yacht’s high-tech touchscreen console, which offers GPS, a retractable windshield, and Jet Stick joystick, also features 3D printed components.

“From the early use of fiberglass in the Bermuda 40 in the 1960s to the adoption of jet drives on the category-defining Picnic Boat, we’ve always worked to combine the latest technology with cutting-edge naval architecture to do what has not yet been done,” says Peter O’Connell, president and CEO of Hinckley.

In order to give the yacht that classic wood aesthetic, Hinckley hand-paints the molded composite structure with wood grain. There will be twin 80-horsepower Deep Blue 80i 1800 motors propelling the boat, each of which is powered by a 40-kilowatt-hour BMW i3 lithium ion battery. Following in the footsteps of Tesla, the Dasher’s electrically powered engine can be fully charged in just four hours.

The yacht was unveiled for the first time at the 47th Newport International Boat Show that took place last week. The Hinckley Dasher will cost over $500,000, and is expected to be delivered to customers next summer. While that price is most certainly outside of the average person’s budget, it’s still intriguing to look at how 3D printing is setting sail upon the maritime industry.

Source: Bloomberg

License: The text of "Titanium 3D Printing Gives All-Electric Hinckley Yacht a Luxurious Look" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.