Stephen Nigro, president of HP's 3DP business, claims that the tech giant has created a "novel 3D metal approach" that could surface in 2018.

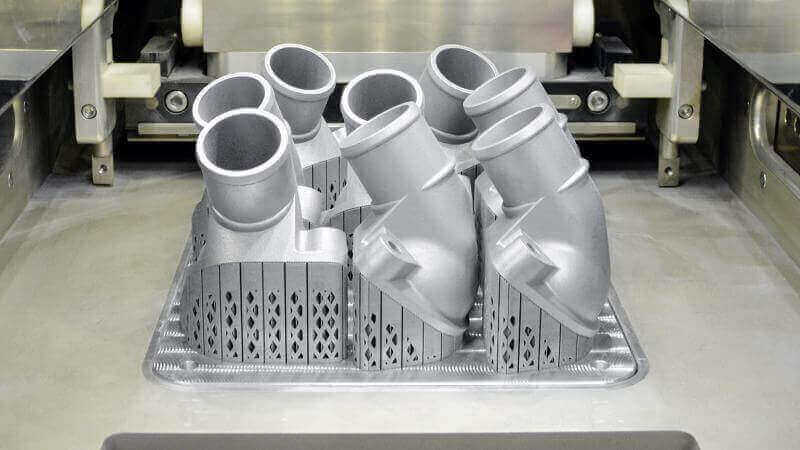

All3DP sits down with Digital Metal's Alexander Sakraditis to discuss the company's high-precision metal 3D printer for small components.

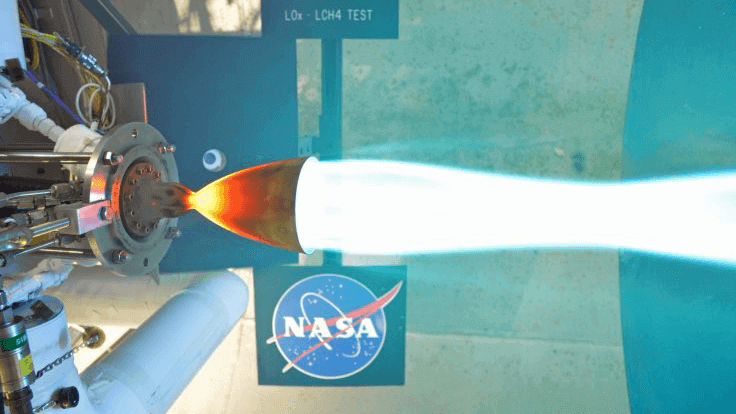

NASA successfully test-fired a 3D printed prototype rocket engine igniter made from two different metal alloys that are fused together.

HRL Laboratories in California have made a metallurgical breakthrough; a technique to successfully 3D print high-strength aluminum alloys.

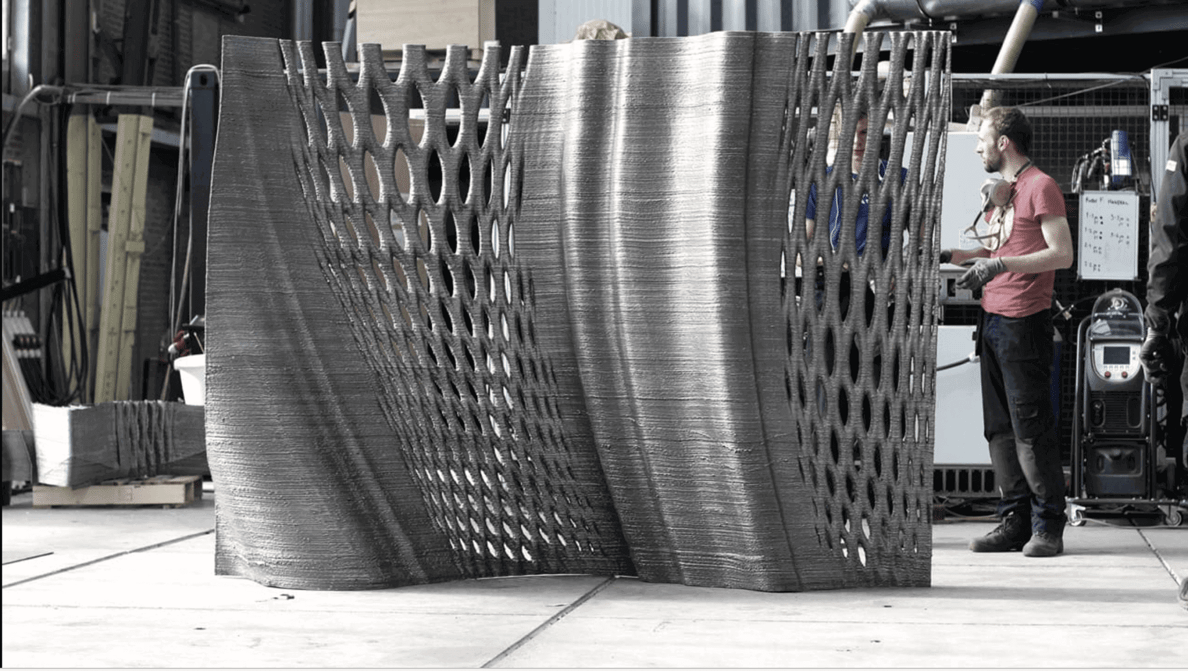

Originally started in 2015, MX3D and Autodesk share an update on their ambitious project to 3D print a functional steel bridge in Amsterdam.

Mercedes-Benz Trucks announces that its first metal 3D printed spare part, a thermostat cover, has passed the quality assurance process.

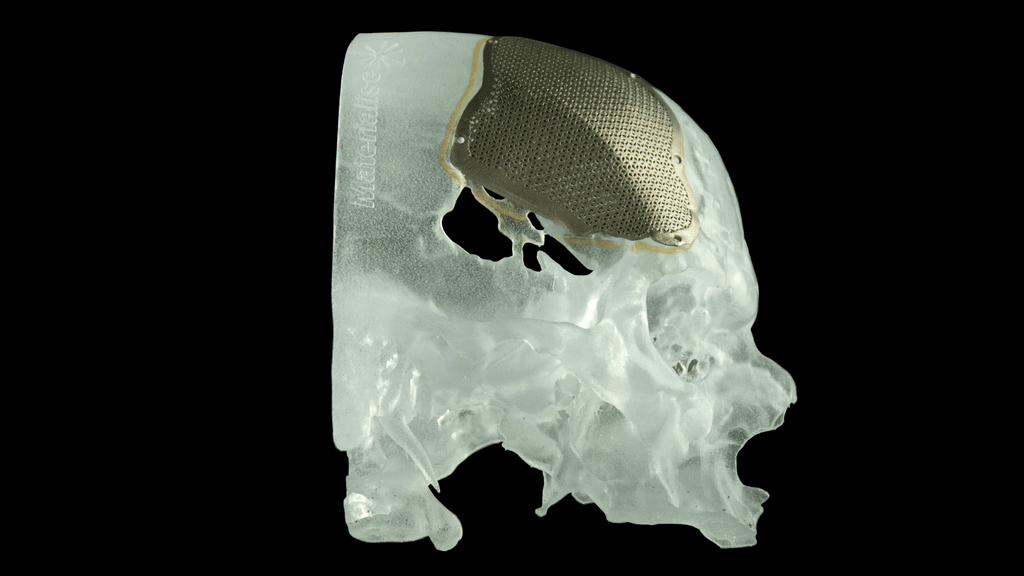

3D printing brings major improvements to facial reconstructive surgery, helping to better recreate a patient's face after serious trauma.

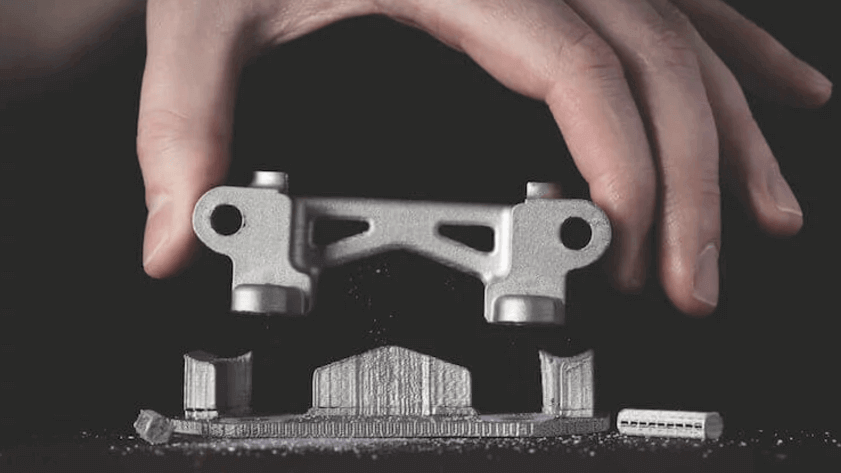

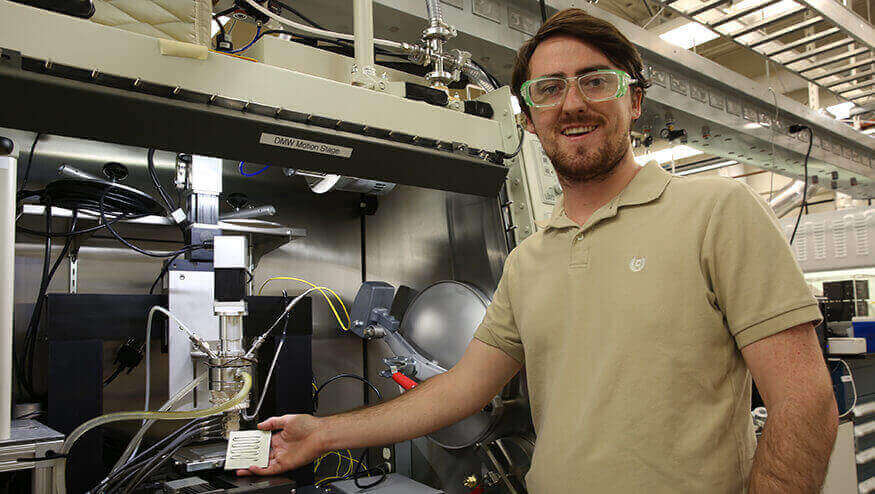

Desktop Metal received $115 million in funding and by September this year, the first 3D printer will be available with the more expensive option ready for next year.

Charles Darwin University is acquiring the LightSpEE3D printer, reportedly faster and cheaper than any metal 3D printer on the market.

Watch magazine Hodinkee and watchmaker Ressence have teamed up to create a one-off timepiece with a special 3D printed case.

Los Angeles based company, 3DEO, is using a new technique called Intelligent Layering to help reduce the costs of metal 3D printing.

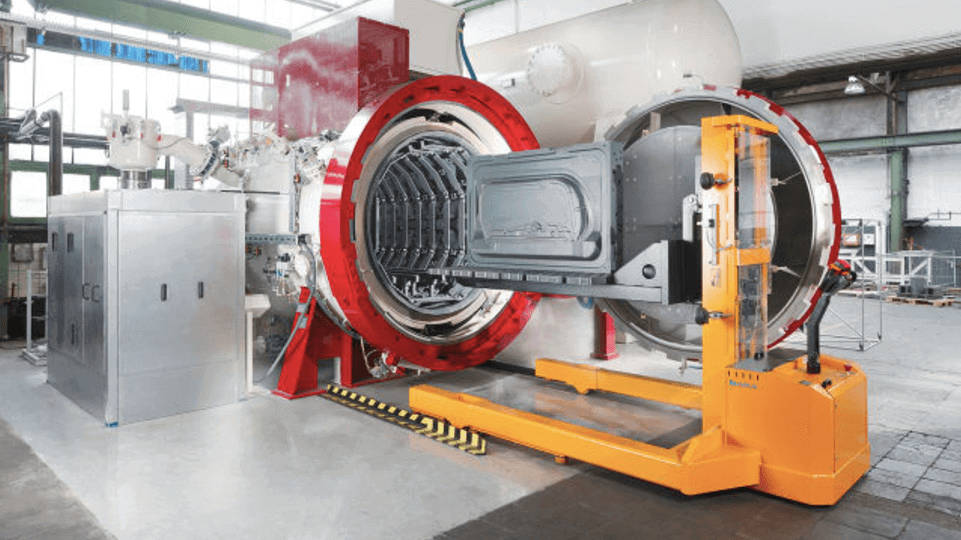

GE Additive has revealed it's building the world's largest metal 3D printer. The as yet unnamed machine is planned for release next year.

ESA launches an Additive Manufacturing Benchmarking Centre in the UK, a "one-stop shop" to explore 3D printing projects for space missions.

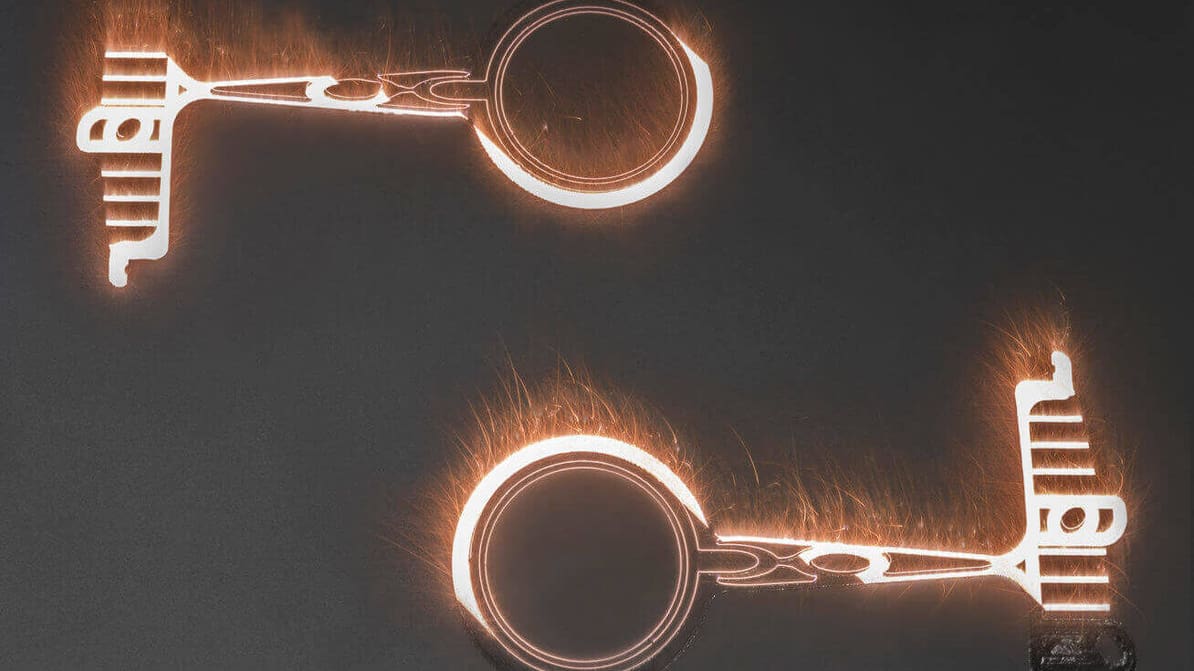

Scientists from the Lawerence Livermore National Laboratory are developing a process that print large metal objects faster than ever before.

The Chattanooga startup Collider is developing the Orchid 3D printer, capable of producing metal objects comparable to injection molding.

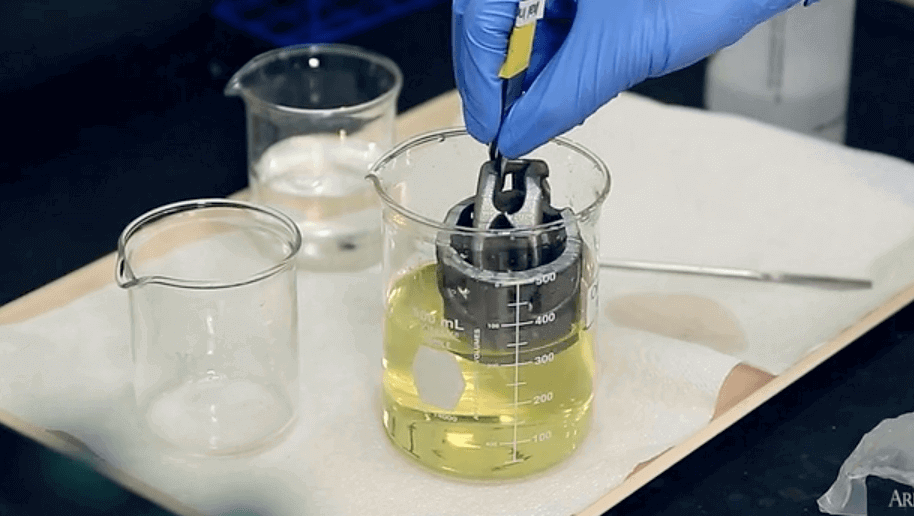

Arizona State University assistant professor has developed a method of dissolving supports to make end-to-end metal printing faster.

Aviation giant enlists Norsk Titanium to make structural parts for 787 Dreamliner aircraft, potentially saving millions in production costs.

Researchers from Lawrence Livermore National Laboratory are developing "direct metal writing" to improve the process of 3D printing metals.

Until now, metal 3D printing is an industrial thing. This might change, as US company "Desktop Metal" brings metal 3D printing to the desktop.

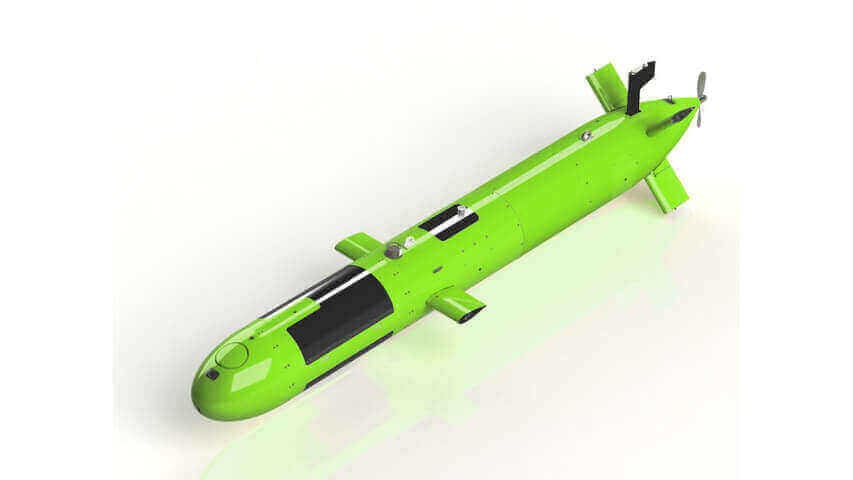

Submarine manufacturer saves major time and cost by 3D Printing a titanium Variable Ballast tank with EBM technology from Sciaky.