Most popular

Nanyang Technological University PhD student Phillip Keane made a robust 3D printed quadcopter drone with ULTEM 9085 material.

The Guinness Book of World Records has certified the world's largest 3D printed object, made by the Oak Ridge National Laboratory in the USA.

New research by VoxelMatters reveals the aerospace industry invested heavily in 3D printing tech and services in 2023 with demand set to increase to $20.5 billion by 2033.

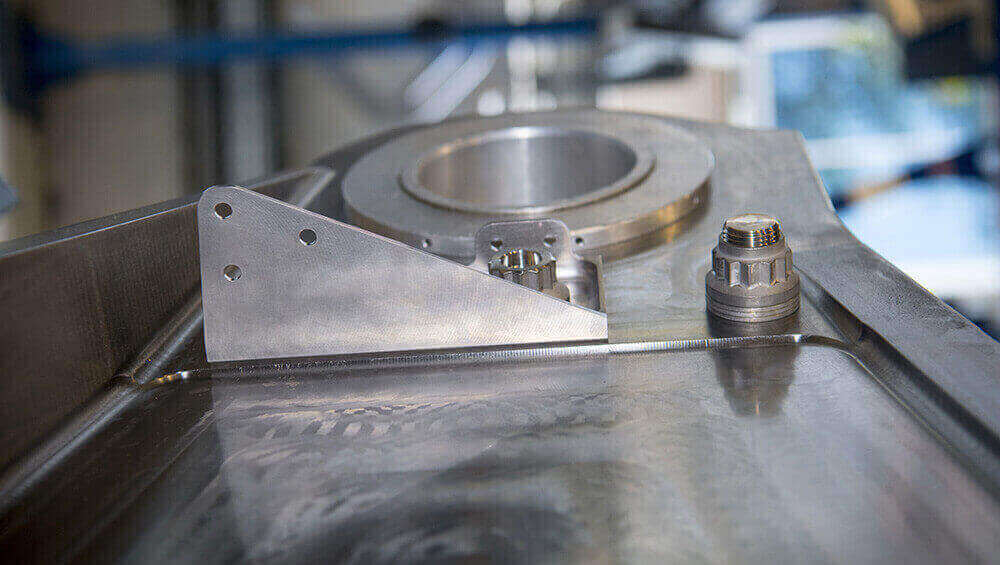

Lockheed Martin is using 3D printing technology to create huge titanium fuel tanks that will be used for satellites, potentially revolutionizing the space launch industry.

Ursa Major's 3D printed Hadley engine powered a new test vehicle aimed at helping the US military develop hypersonic capabilities faster.

Air New Zealand has partnered with Zenith Tecnica, a company which specializes in 3D printing titanium, and will be using its equipment, such as Arcam's Electron Beam Melting (EBM) process to develop parts and tools.

Oerlikon, the technology and engineering group, is working with Lufthansa Technik, a provider of maintenance, repair and overhaul (MRO) services, to establish robust and repeatable 3D printing processes for in the aircraft MRO industry.

Big Air meets Big Printing. BigRep and Etihad Airways Engineering announce plans to collaborate on developing next generation additive manufacturing solutions for the aerospace industry.

Following a successful January test launch of their Electron booster with 3D printed components, US private space firm Rocket Lab plans to go ahead with its first fully commercial mission later this month.

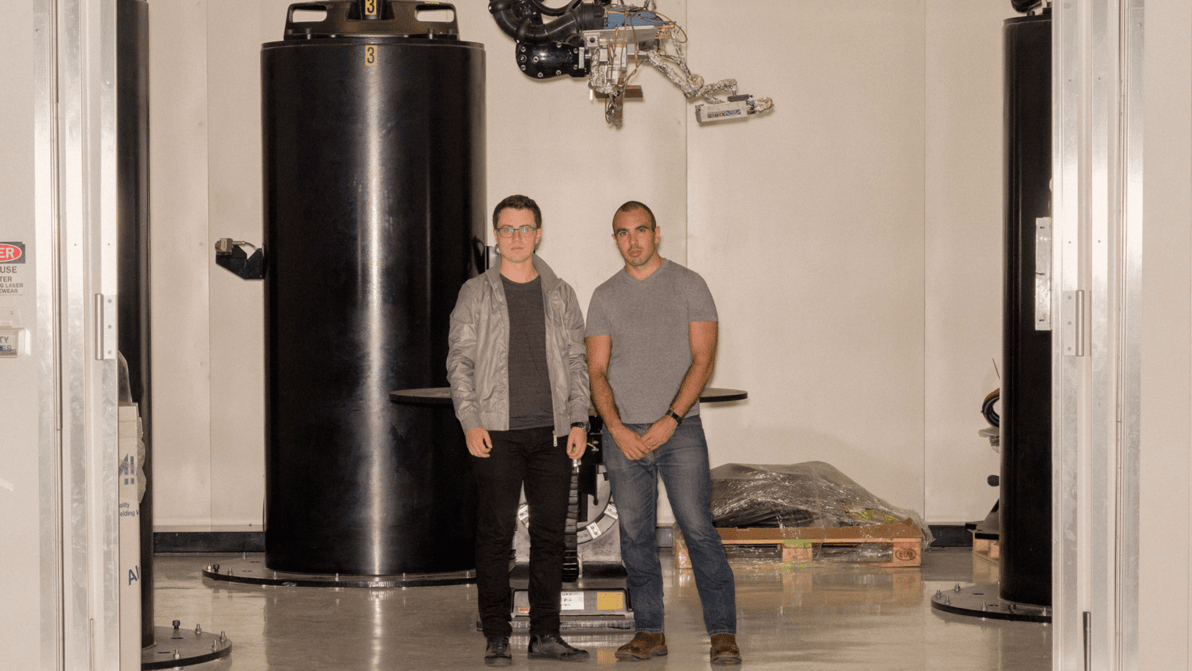

The Los Angeles startup Relativity Space has raised $35 million in its latest funding round led by Playground Global and other investors. The financing will enable the aerospace company to expand, while also paving the way for it to refine and test 3D printed rockets.

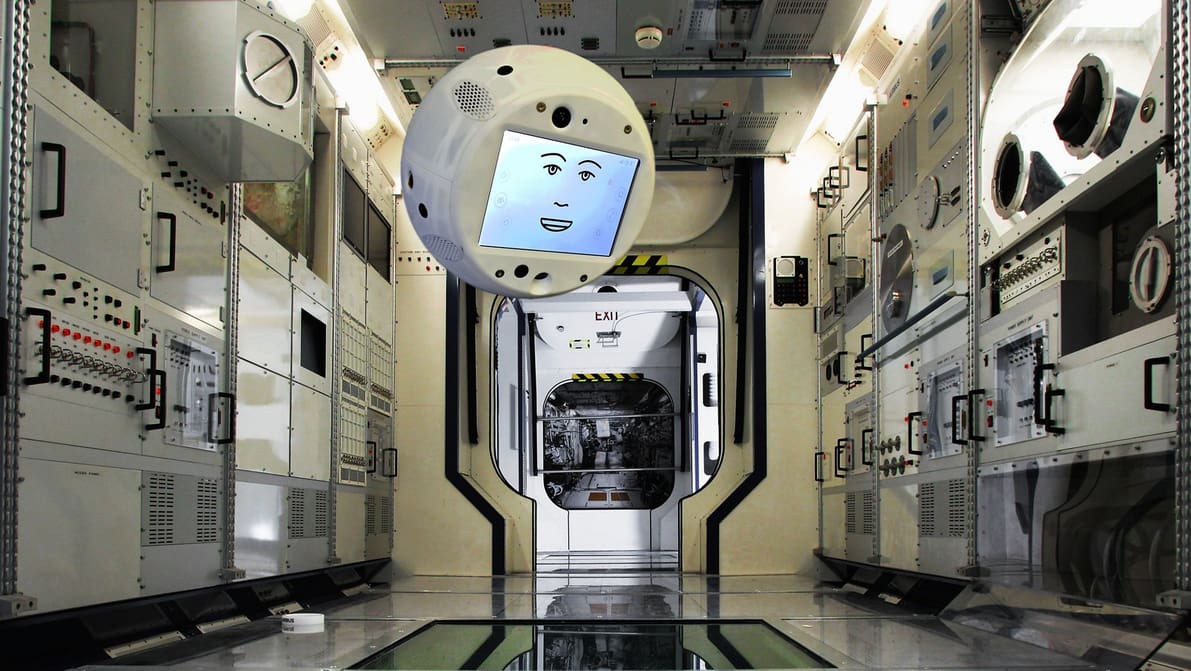

Airbus is using artificial intelligence from IBM to create an AI robot that will live on the International Space Station. This 3D printed mission and flight assistance system is called the Crew Interactive Mobile Companion, also known as CIMON.

French firm Stelia Aerospace has lifted the lid on its newest innovation. Using WAAM (wire arc additive manufacturing), the company has demonstrated metallic self-reinforced aircraft fuselage panels that cut out a costly and time consuming assembly process.

Latécoère, the French aicraft design and manufacturing group, is using Stratasys FDM 3D printing technology to speed up its production and development process. So far, the results have been positive.

The X-plorer engine is the first of its kind: A working 3D printed jet engine. It consists of more than 260 3D printed parts.

The California startup Relativity Space Inc. is building rockets at a faster and more affordable rate using only gigantic 3D printers.

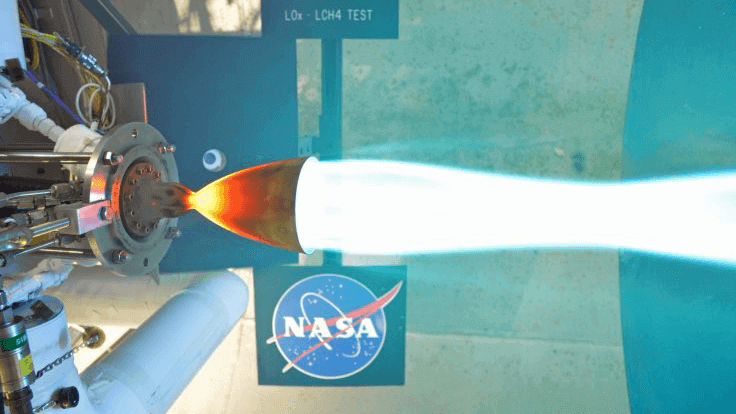

NASA successfully test-fired a 3D printed prototype rocket engine igniter made from two different metal alloys that are fused together.

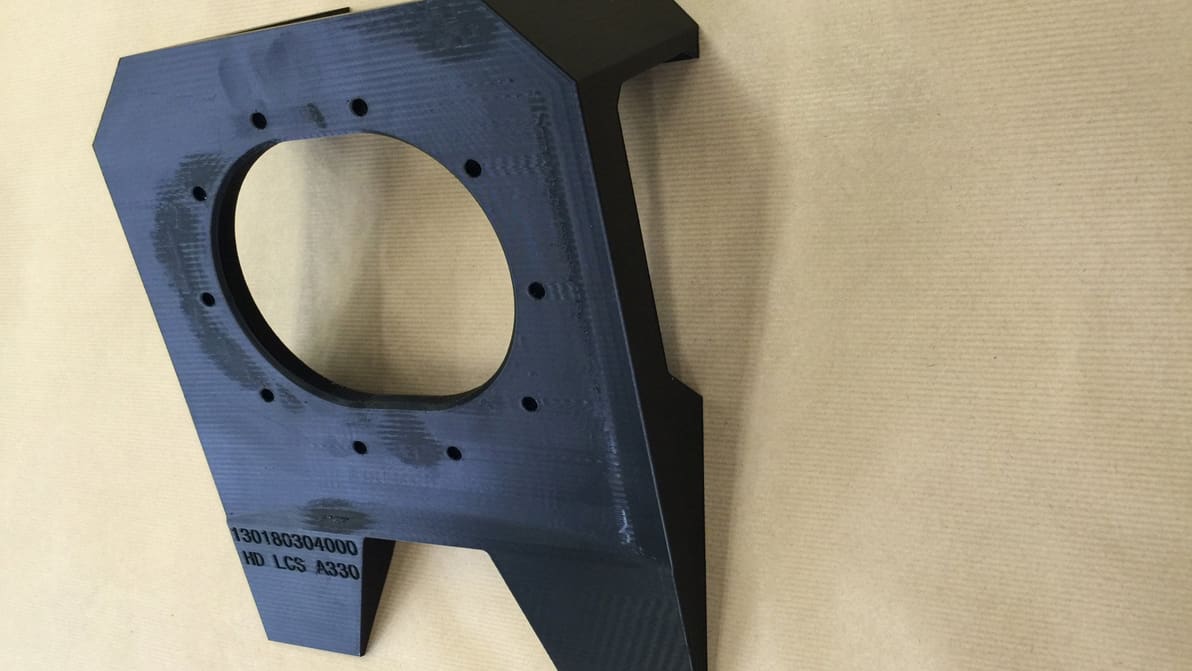

Aeronautics company, Airbus, has installed of a titanium 3D printed bracket for the engine pylon on its in-series production A350 XWB.

In just four months, a team of Australian engineers designed, 3D printed, assembled, and tested an aerospace rocket engine.

The UK-based Airbus Defence and Space is developing metal 3D printed radio-frequency (RF) filter prototypes for telecom satellites.

Ever wished you could fly? Gravity Industries is making an Iron Man suit which has 1,000 horsepower and components 3D printed in metal.