With a combined hardware, software, and firmware update, Ultimaker address some issues of their 3D printer flagship Ultimaker 3. Here‘s what‘s improved.

Dutch 3D printer manufacturer Ultimaker just came up with some interesting new updates for their printers.

Ultimaker 3 Update #1: Speeding Up with 8mm Print Cores

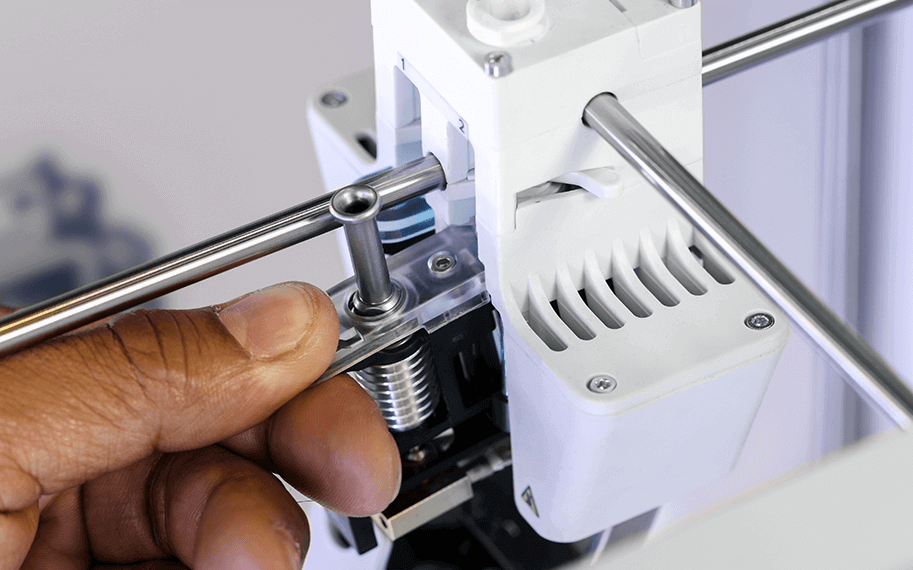

The Ultimaker 3 and its bigger brother, the Ultimaker 3 Extended, are excellent machines (review here), but they are printing notoriously slow. Ultimaker tackles the problem by decreasing the print resolution. They introduce a new nozzle size for their exchangeable “print cores”. While the already existing 0.4 mm print cores can print in great detail, the new 0.8 mm ones are designed to achieve faster print results like quick mockups and initial prototypes. The 0.8 mm print cores can print in different quality profiles. They are plug and play ready. Exchanging them should be a matter of seconds.

The two new 8mm print cores (AA and BB) will set you back $200.

Ultimaker 3 Update #2: New Profiles for Professional 3D Printing Materials

The company has updated the 3D printing profiles for more professional filaments like CPE+, PC, and TPU 95A. Also, profiles for soluble PVA have also been updated, improving the reliability of printing with PLA/PVA and enabling the combination of CPE/PVA.

As usual, Ultimaker is offering the filament on their website. A 500-gram spool of Ultimaker PP will set you back $40. Of course, you are not limited to the Ultimaker brand and can choose your materials from any manufacturer you like.

Ultimaker 3 Update #3: Closing the Box with the “Advanced 3D Printing Kit”

To make the best use of the new materials, Ultimaker now offers an “Advanced 3D Printing Kit” for $90. This kit is specifically designed to ensure temperature consistency throughout the build room. It stops heat from escaping, creating a constant temperature of 45 ºC, while protects the print from external influences. The front enclosure protects prints from air currents and ensures a stable temperature environment within the printer.

Also new are adhesion sheets ($20 per pack), that will give you better adhesion surface for the first layer (although for most prints some glue stick will to the trick). Ultimaker recommends for PP, CPE+, or PC materials.

Ultimaker 3 Update #4: Firmware Updated to Version 3.7

The latest firmware update includes a number of improvements. Among its most significant new features is the ability to restart a print directly from the Ultimaker 3 – without the need to start up Cura – and an improved material change procedure. When changing materials, the Ultimaker 3 automatically flushes out all residue material, ensuring the print core is fully clean when a new material is inserted.

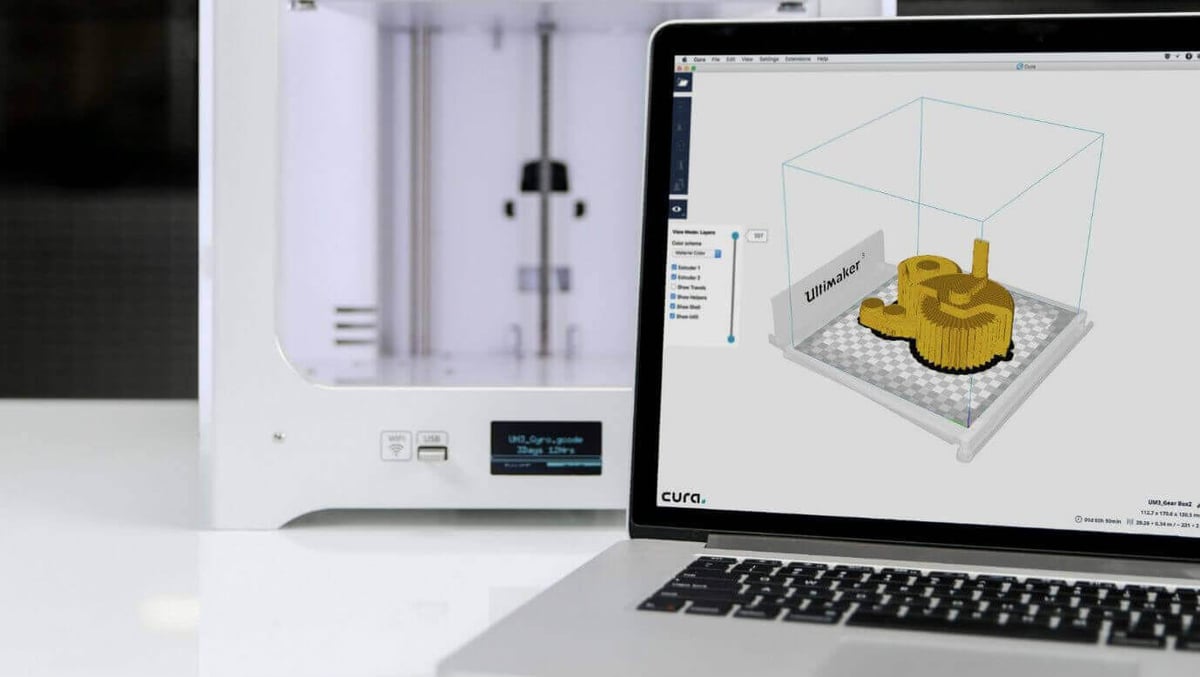

Ultimaker 3 Update #5: Slicing Software Cura Now Officially Updated to 2.6.1

A version of the popular 3D slicing Software Cura 2.6 has been available in public beta since May (more here). Now the official version Cura 2.6.1 is available for download. Here are the most important updates:

- Model auto-arrange. Ultimaker improved placing multiple models or multiplying the same ones, making it easier to arrange on the build plate. If there’s not enough build plate space or the model is placed beyond the build plate, users can rectify this by selecting ‘Arrange all models’ in the context menu or by pressing Command+R (MacOS) or Ctrl+R (Windows and Linux). Cura 2.6 beta will then find a better solution for model positioning.

- Local version folder. Cura 2.6 beta has local version folders, which means the new version won’t overwrite the existing configuration and profiles from older versions, but creates a new folder instead. This means you can safely try out new beta versions and roll back with without the danger of losing printer profiles.

- Better support adhesion. Ultimaker added extra support settings to allow the creation of improved support profiles with better PVA/PLA adhesion. The Support Interface settings, such as speed and density, are now split up into Support Roof and Support Floor settings.

- Multi-extrusion support for custom FDM printers. Custom third-party printers and Ultimaker modifications now have multi-extrusion support.

- Gradual infill. You can now find the Gradual Infill button in Recommended mode. This setting makes the infill concentrated near the top of the model – so that you can save time and material for the lower parts of the model. This functionality is especially useful when printing with flexible materials.

- Support meshes. It’s now possible to load an extra model that will be used as a support structure.

- Molds. An experimental feature: Users can use it to print a mold from a 3D model, which can be cast afterward with the material that you would like your model to have.

- Towers for tiny overhangs. Ultimaker added a new support option allowing users to achieve more reliable results by creating towers to support even the smallest overhangs.

- Cutting meshes. Easily transform any model into a dual-extrusion print by applying a pattern for the second extruder. All areas of the original model, which also fall inside the pattern model, will be printed by the extruder selected for the pattern.

License: The text of "Ultimaker Add Bigger Print Cores, Pro Filament Profiles, Cura Updates" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.