Altair, APWORKS, EOS, and other leading manufacturers partner up under the 3i-PRINT program to 3D print front-end structure for VW Caddy.

All across the globe, car manufacturers are increasingly integrating 3D printing into their production process. Whether its used to renovate a 1954 Pininfarina Jaguar or optimizing the automotive design cycle of future vehicles, additive manufacturing is playing a critical role in this sector.

In order to showcase this potential, a group of leading manufacturers are teaming up for the 3i-PRINT partnership project. Participants include Altair, APWORKS, csi entwicklungstechnik, EOS GmbH, GERG, and Heraeus. The collective, initiated by csi entwicklungstechnik, allows these pioneering manufacturers to research and develop breakthrough concepts together. The overall aim of 3i-PRINT is to demonstrate and exploit the potential of industrial 3D printing in automotive manufacturing.

The first result of this all-star collaboration is a Volkswagen Caddy fitted with a 3D printed front-end structure.

3i-PRINT Project: Demonstrating Value of Industrial 3D Printing in Automotive Manufacturing

From the first conceptual design to the final car, the entire project took nine months to complete. Not only is the 3D printed front-end section of the car exceptionally light and stable, it also features a high degree of functionality. In order to achieve these characteristics, the team used Altair’s software solutions to optimize and simulate the organic design.

This enabled the experts at csi entwicklungstechn to reduce the space and overall weight of the front-end structure. The company develops modules for vehicle bodies, interiors, and exteriors, and led the development and production of the VW Caddy. GERG, a leading supplier of automotive and aerospace solutions, helped connect the 3D printed components to the final frame.

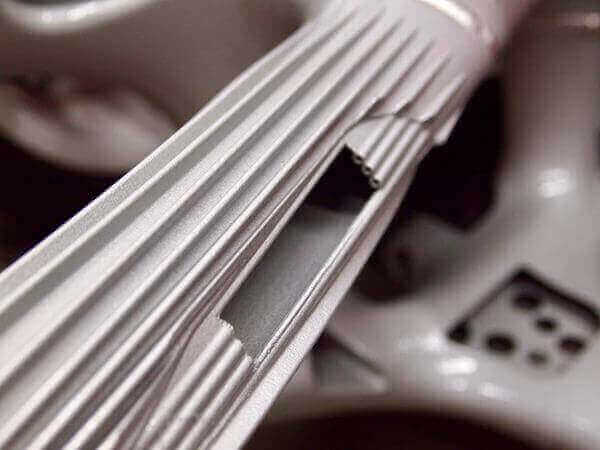

After the simulation and design of the automotive concept was confirmed, the Airbus subsidiary APWORKS prepared the final components for 3D printing. APWORKS uses an additive manufacturing system developed by EOS, a stalwart in the industrial metal 3D printing sector. Finally, the metal powder specialist Heraeus supplied the high-strength aluminum alloy Scalmalloy used to manufacture the components.

“We are proud to present the Caddy with an exemplary new additively manufactured front end structure. The new structure and the contrast between old and new impressively demonstrates the potential that 3D printing and functional integration offer, particularly for the automotive industry,” said Stefan Herrmann of csi entwicklungstechn.

All in all, the 3i-PRINT project proves that innovation blooms even quicker when manufacturing titans partner up. You can catch the VW Caddy live at Converge 2017 in Essen or formnext 2017 in Frankfurt.

Source: Altair

License: The text of "VW Caddy Fitted With 3D Printed Front-End Structure for 3i-PRINT Project" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.