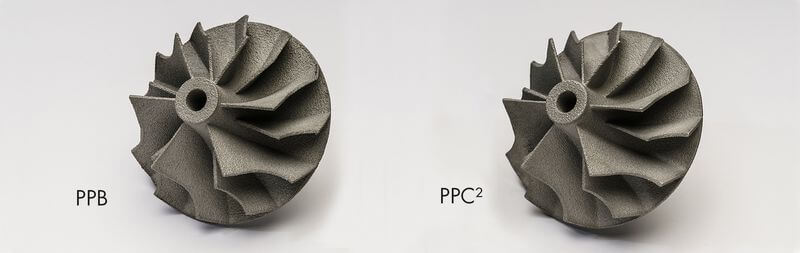

3D printer manufacturer Voxeljet announced the release of PPC², a new powder technology that wants to raise the level of detail of investment casting parts.

Voxeljet can already pride itself for a portfolio of high-speed, large-format 3D printers. In addition, it offers an online 3D printing service that focusses on industrial and commercial customers.

PPC² is an improvement of the PMMA technology (a variation of binder-jetting) that is also offered by Voxeljet. In comparison, the new process allows for an increased resolution.

The plastic powder used in PPC² has a grain size of only 37 micrometers. As a result, parts printed with this 3D printing process boast a layer thickness of only 100 micrometers. With regard to investment casting, it is noteworthy that the material leaves almost no residual ash.

It is Voxeljet’s stated goal to make the PPC² process an affordable 3D printing asset for foundries that focus on investment casting parts like turbine impellers, and turbine blades.

How does Voxeljet’s PPC² process work?

Building on the established PMMA technology, Voxeljet harnesses a high-definition printhead that prints at a resolution of 600 dpi. It is also capable of reducing the grain size and layer thickness.

However, the technology will be limited to Voxeljet’s own 3D printers. The company will use it as a selling point for its VX200 3D printer that features a build volume of 274 x 174 x 127 mm.

Voxeljet’ product manager, Tobias Gruen, promises that “the use of a new and more compatible binder ensures that our industrial printheads have an increased lifetime that performs at a consistent printing quality.”

In case you are interested in the new PPC² process, Vvoxeljet offers benchmark parts that can be ordered from both its headquarter in Germany and its US subsidiary.

Voxeljet will present the new 3D printing process at the investment casting conference ICI, in Covington, Kentucky that takes place October 15th to 18th 2017.

License: The text of "Voxeljet’s PPC²-Technology Promises Better Quality of Investment Casting Parts" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.