Who should read this: Anyone who’s interested in taking a 3D printing workshop at a FabLab.

The newly reopened FabLab Berlin is offering workshops in various processes involved with 3D printing. I am an absolute newcomer to the field. So I booked a 3D Printing Introduction workshop for €15 ($17) on a summer evening. In the large sunlit co-working space of the purpose-built lab at Prenzlauer Allee 242, the workshop participants gather around a table with laptops. There is chilled-out music and we are in wonderful facilities, surrounded by new equipment.

One idea behind FabLabs is about making the technology available to everyone, not just students.Our group includes an Australian who works in metal fabrication and wants to learn more digital skills, a machinery saleswoman from Taiwan and a German who is considering buying her own 3D printer. We pass around objects printed at the FabLab including an intricate architectural model and a representation of a woman’s bottom.

Covering the basics with this 3D Printing Workshop

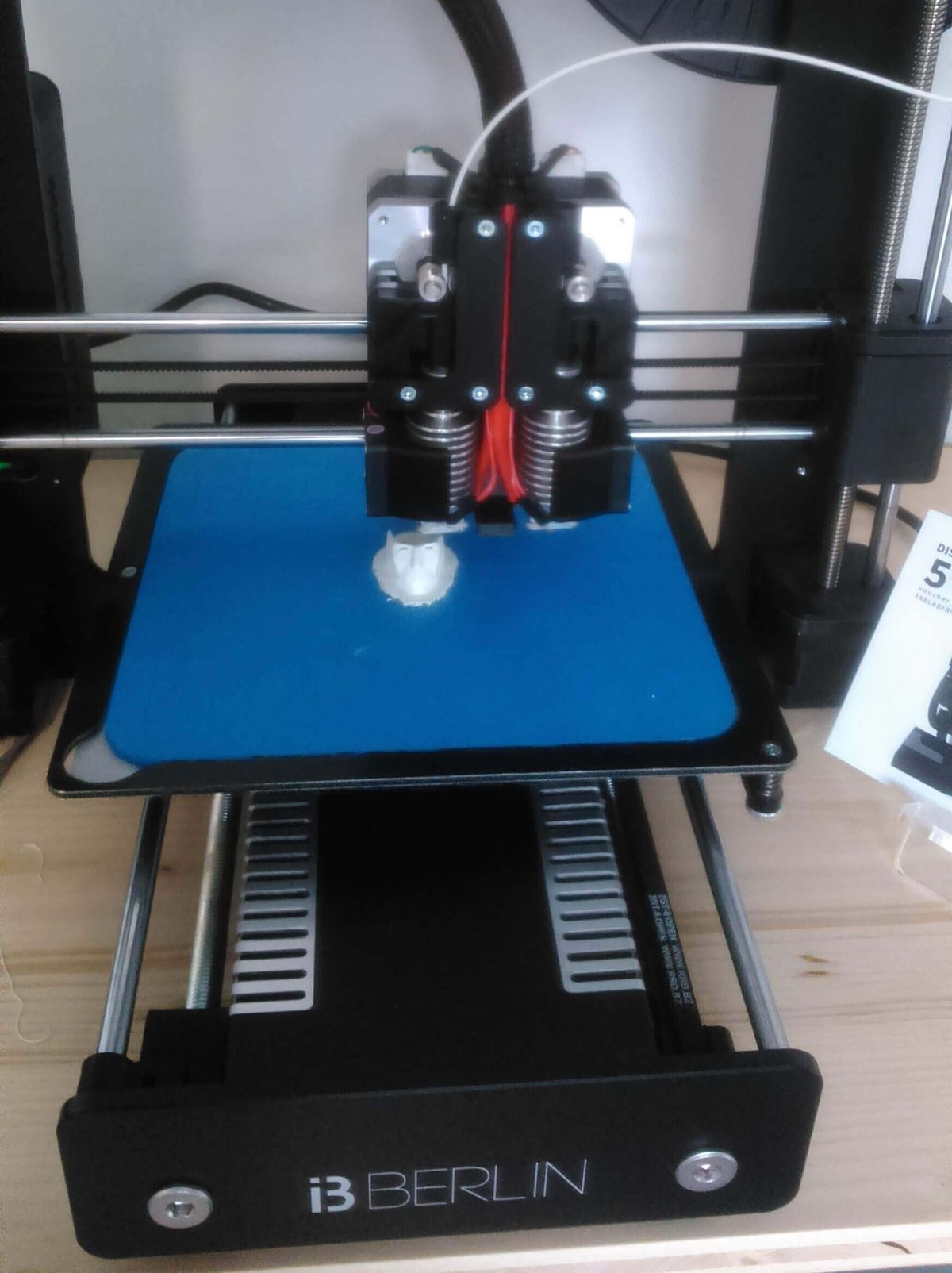

The workshop is billed as allowing us to learn the basic principles of 3D printing and make our own object using one of the FabLab’s I3 Berlin printers, built locally. The workshop is led by Park, who speaks clearly and precisely. He describes the very basics for novices like me: how 3D printing is the process of making a virtual file into a physical object. He then gives a quick explanation of various printing methods including FDM (Fused Deposition Modelling), which we will be using today, Selective Laser Sintering (SLS) and Stereolithography.

Park explains how the first stage is the model and about using 3D modelling software. We then discuss the next stage: the slicing programme, which translates the model into coordinates that a 3D printer can understand.

This evening, we are using Cura, an open-source slicing program. On Cura, we enter lots different numbers: including layer height (the smaller the layer, the smoother the end product) and shelf thickness (Park explains that 3D prints are mostly hollow which saves time and material and how CURA automatically creates an internal grid for the objects which makes them stable). We are also shown how to set the print speed (we want to be as fast as possible but at a certain point vibration increases the likelihood of the print failing) and print temperature (today it’s 200 degrees C).

3D Print Your First Object

I am then able to choose an object to make from the FabLab collection on Thingiverse.com. The objects include ornaments, iPad accessories and cookie moulds. They are all ‘short prints’ of twenty to thirty minutes. I choose a ring decorated with a robotic mask face, because it looks cool and it will be nice to have a piece of jewellery that I can wear. I download the files into Cura then transfer them (in .gcode format) onto an SD card.

We are shown how to insert the SD card into the printer and start printing. On the display, I watch the bed heat up. Then it begins to print: I watch it extrude filament (in this case, PLA from plant material) in layers, first marking out the base then beginning to build up my ring.

By seeing with my own eyes, I begin to understand how the bed moves in X direction while the extruder moves Y and Z. Layer-by-layer, a tiny face emerges: chin, then nose then eyes. It’s exquisite to see the printer in action and exciting to see an object emerge that a moment ago had just been a model on a screen.When the print is finished, after around twenty minutes, the ring is peeled off the print bed and the ‘raft’ or base is snapped off. It fits my finger perfectly.

When the print is finished, after around twenty minutes, the ring is peeled off the print bed and the ‘raft’ or base is snapped off. It fits my finger perfectly.

I am wearing it now, as I type this, as a memento of my first journey into learning about this amazing technology. The workshop gave me an excellent first basic understanding of 3D Printing, meaning I can now start to imagine its applications and possibilities.

Thanks Fab Lab Berlin!

(Image source: Fablab Berlin)

If you want to print out the ring for yourself, you can get the files at Thingiverse.

If you don’t own a printer and want to order it, you can use our 3D Printing Price Comparison to find the best online 3D printing service.

For more information, here’s All3DP’s interview with FabLab Berlin, which took place at 3D Printshow Berlin 2015.

License: The text of "What To Expect From a 3D Printing Workshop at Fablab Berlin" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.