What does the future hold for 3D printed food? And how close are we to fine dining with 3D printed food in a Michelin starred restaurant?

It’s easy to fall back on images from popular culture when thinking about 3D printed food. From the Star Trek replicator to robot Rosie cooking for the Jetsons, food from a machine is key to how we imagine the future. But what does the future of 3D printed food really look like? A recent series of articles from Forbes digs in.

Don’t try this at home

The first thing to note is just how many challenges there are to bringing 3D printed food to the table. While you might be able to feed coffee filament through your MakerBot, you can’t use it to print a coffee mug made of edible coffee (yet!).

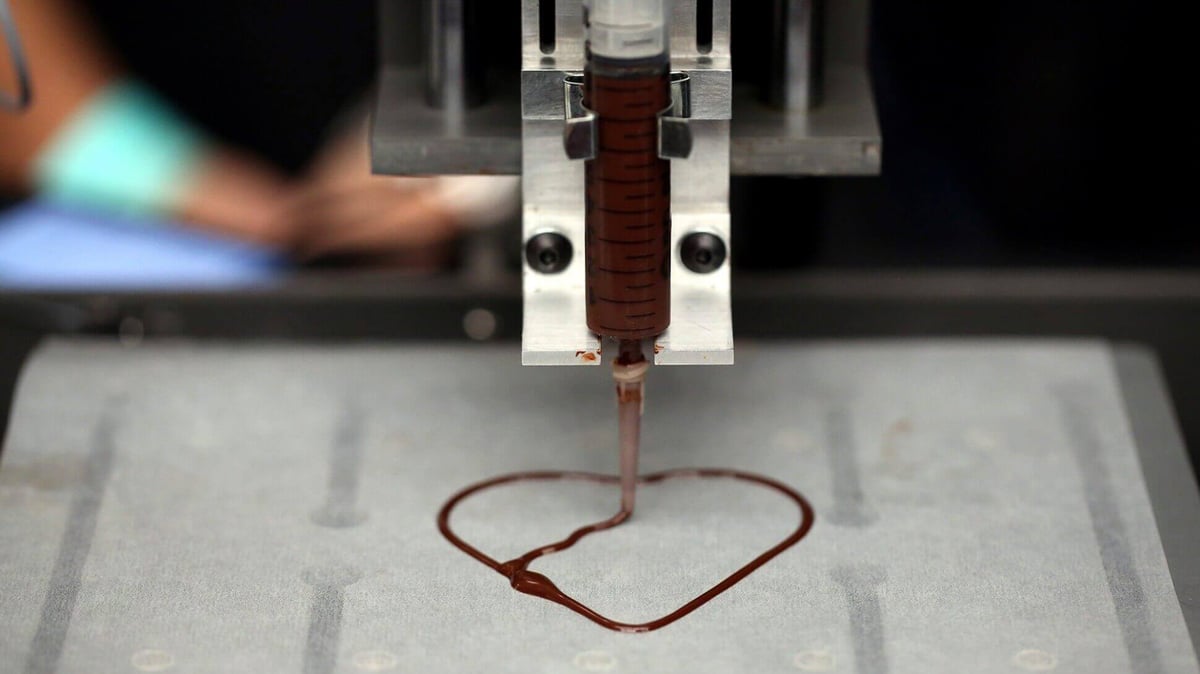

The first obstacle to the widespread use of 3D food printers is their cost and relatively limited production: these extruders are specialized — and expensive — machines, many of them first-generation models. Some, though, are mixed-materials printers like 3D By Flow, which can switch from a food-safe nozzle to others that print metals or ceramics.

There are also limitations to the materials that these machines can print. One of the most popular models, the ChefJet Pro, is pretty much sweets-only, designed to build up thin layers of sugar. Other printed food materials need to be sturdy enough to hold their shape, but flexible enough to pass through the precise nozzle of the printer. If liquids are set with agar-agar, a vegetarian gellifying agent, for example, these proportions must be set carefully and recalibrated in advance of each batch.

Nor is this process instant. When the average diner is presented with a 3D printed honeycomb sphere made out of honey, they might imagine it being printed like a laser printer — quickly, to order. But additive food printing takes a long time, from 10 minutes to an hour per plate.

Will 3D printing food disrupt the entire concept of fine dining?

In addition to questions of these printers’ readiness, there are also much bigger questions that 3D printing raises for fine dining. How will 3D printing change the very concept of fine dining itself? Will it “disrupt” fine dining the way that some predict it will manufacturing?

Some, like Columbia University professor Hob Lipson, think so — they argue that 3D printing will democratize fine dining. He imagines that one might walk into a store and buy a cartridge ready to print a celebrity chef’s signature sauce or dessert — that 3D printer schematics might be exchanged, bought, or sold as recipes.

Whether you agree with Lipson or think that 3D printed food will remain an elite novelty, the question of food’s relationship to technology is still a relatively divisive one.

Where have all the “deconstructed” dishes gone?

There does seem to be a recent trend towards elite, fine dining that stresses its authenticity and earnestness, not its tech-savviness (noma, we’re looking at you!). This “authentic,” “clean food” trend pushes against former food innovators using technology in the kitchen — chefs whose bubbles, foams, and “deconstructed dishes” have been associated with the terms “moleculary gastronomy” and “the New Cookery.”

But even though chemistry-heavy El Bulli and New York’s wd50 have closed, that doesn’t mean the end of technology and food’s partnership. It may be the beginning. As culinary innovation moves away from the restaurant and towards centers that are completely devoted to culinary innovation — like the Nordic Food Lab or the El Bulli Lab — these expensive and innovative technologies might take root in an environment that is not dependent on nightly sales to recoup these investments.

To chefs like three-Michelin-starred Heston Blumenthal, 3D printers don’t pose a threat, but a unique and exciting challenge. As the Culinary Creative Directors at 3D Systems Liz and Kyle von Hasseln state, a turn towards 3D printing is “putting more capabilities into chefs’ hands and tapping those skills to bridge the gap between hard earned manual artisanship with a new form of digital artisanship.” They are so committed that they have recently opened a Culinary Lab in LA that will host workshops and demonstrations of the applications of 3D printing for fine dining.

For 3D printers to find their way into restaurant kitchens, chefs, engineers, and designers will have to work together closely to make these ideas a reality. And that collaboration will be exciting — and unprecedented. The upshot? A sample meal by chef Mateo Blanch at the 3D Printshow in London featured not only confections, but octopus served with a potato frame and caviar crackers.

The image above is from chef Mei Lin’s demo at the LA Culinary Lab, a collaboration with 3D Systems. The passionflower, printed from dehydrated passionfruit puree, is designed to crumble and mix into the already-fanciful dessert below of dehydrated strawberry powder, bee pollen, and something advertised as toasted yoghurt (we’re as curious as you are!).

And that’s what’s encouraging chefs to tinker with the technology: they’re already artists and innovators in the first place. For a playful culinary mind, or a master chef, a 3D printer opens up a great many possibilities. It’s inconceivable that new tools like the food printer could stay out of the kitchen for very long.

License: The text of "When Will We be Fine Dining with 3D Printing?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.