Why you should read this: Because 3D printing has the potential of producing less waste, and because it has an impact on our environment? Yeah, right. You might want to know some facts first.

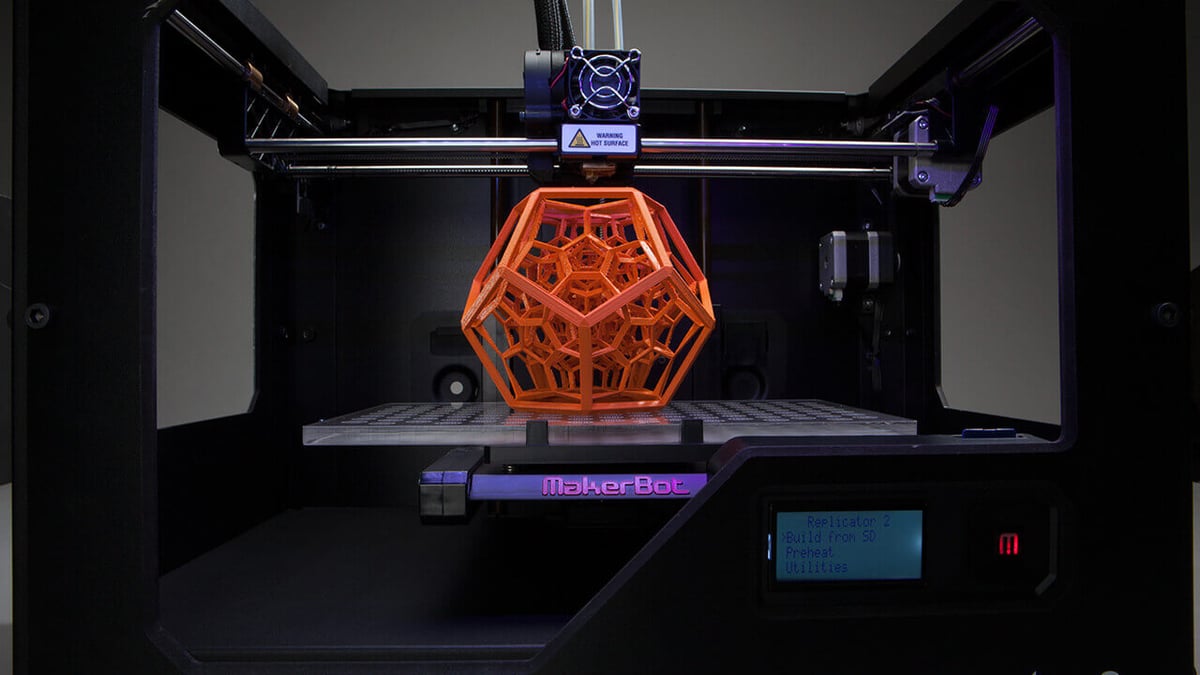

3D printing is a very disruptive technology. It enables us to produce items that would otherwise cost a lot of money and time to build traditionally. For parts you only need once, like prototypes or spares, production on demand isn’t even possible. There are too many of them; they are too different, and it would be costly to let them get produced. So 3D printers can save a lot of money and valuable time. You don’t have to wait until something gets shipped from around the world. Producing items can mostly be done ad hoc. No other manufacturing technology can do all that so easily.

3D printing seems to have an enormous ecological advantage. When you only use up the material needed to build the exact object and don´t have to package and transport it across the globe, 3D printing finally puts a solution to save the environment right in our hands.

Or are we missing something? The big picture, any important details?

The big picture

The impact of a 3D printed product on the environment can’t be easily determined. You have to include every step from the mining of raw materials, from refineries until the actual manufacturing process of the object takes place. Finally, you have to consider if a product lifecycle is as short as one use or if the product may outlive yourselves.

The ecological footprint of oil is lousy to say the least. Oil pollution, waste from oil refineries, the emissions from burning oil and oil-based fuels when you transport anything…

3D printing can´t gain ground in this aspect.

The energy use of 3D printing can also be relatively high. On the one hand, with plastic parts you need to produce in large quantities, the impact of injection molding is less. With metal objects, on the other hand, 3D printing often wins against traditional manufacturing. Small numbers of objects are easier done without the whole molding process to spare the environment.

Also a problem when heating plastics are the fumes. Toxic in most cases and often existing as fine particles, they should best be filtered. So the manufacturing process does gain ground depending on the use case.

One plastic is not like another

The difference between ABS and PLA plastic comes into effect not only regarding object properties, but especially environmental impact. PLA is the most commonly used plastic in home 3D printers. It is biodegradable and should, therefore, be relatively eco-friendly. PLA is made from starch, and that’s where it is hard to get conclusive numbers. How many plants, how many fields that could otherwise be used for the production of food are used to produce plastic? How much waste is produced in the process of making PLA?

The plastic consumption as a 3D printing material today is estimated at 13.6 million kilograms per year, and it’s projected that this value will see an annual growth of 40% until 2020. Most of this 3D printing filament is made from virgin plastic – that means fresh plastic made from oil. The petroleum used to produce 1 kilogram of plastic (a single standard 3D printer cartridge) equals almost four times as much in carbon emissions. By 2020, approximately 1.4 million barrels of oil will be used to produce only 3D printing filament, generating 363 thousand tons of carbon emissions.

These numbers aren’t good. By using recycled plastics, the carbon footprint of (FDM) 3D printing can be reduced by up to two-thirds. The crowdfunded Dimension Polymers 3D printing filament does just that- producing filament spools from recycled ABS plastics. Their product is made from at least 95% recycled ABS plastic and the spool and packaging are made from recycled materials.

Know your Mnemonics

So if you want to 3D print and produce the minimum amount of pollution, I’ve got a few mnemonics:

- PLA > ABS

- Mass production: Injection molding > 3D printing

- Prototypes and small quantities: 3D printing > injection molding

- With metal objects: 3D printing > CNC milling

- Hollow objects = saved material =saved environment

- Print multiple parts at once if possible

- Print at low temperatures

- Local on demand production is a big win

- Waste is waste, no matter where it comes from

- Think twice, print once!

License: The text of "Will 3D printing save our environment?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.