The world’s first ever implant surgery with a 3D printed sternum — made from Titanium – was successfully performed in Spain.

The patient had lost a significant number of bones in his chest because of a chest wall sarcoma, a type of cancer. The intricate geometrical shapes in the area — and the need for strong, durable materials — ruled out the possibility of using traditional prosthetics. So the surgeons investigated the possibility of 3D printing a custom sternum and rib cage from titanium.

The doctors used high-resolution CT scans to develop a custom solution, including ribs for the prosthetic to be securely bolted on to the remaining bones. The CAD file was then given to Melbourne-based implant experts Anatomics, who customized the design to achieve a perfect fit for the patient.

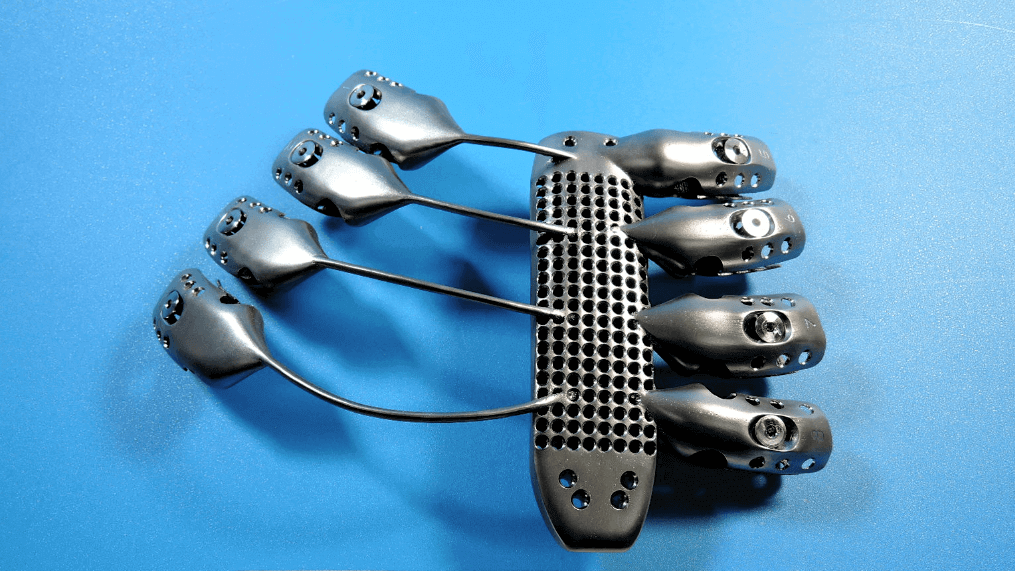

3D Printed Sternum made with Electron Beam Melting technology

The actual materialization of the 3D printed sternum and rib cage was undertaken by CSIRO, which is an Australian government scientific organization employing experts in all kinds of engineering. CSIRO used an Arcam Electron Beam Melting (EBM) metal printer to produce a very high quality print in their dedicated 3D printing lab.

The titanium prosthetic was couriered to Spain and the surgeons performed the implant surgery with great success. The patient was discharged from the Salamanca hospital only twelve days later, becoming the first person to ever receive an implant of this kind.

As high-quality and accurate 3D printers become more accessible for hospitals, doctors will acquire the ability to create highly customized solutions for their patients, offering medical services in levels that were never possible before. The patient with the 3D printed sternum is very likely going to be the first of many.

License: The text of "World First: Cancer Patient receives 3D Printed Sternum" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.